Internal nitriding of high entropy alloys

F. Lukáča,d, M. Klementováb, M. Lac, L. Cvrčekc, P. Minárikd, J. Kozlíkd

aInstitute of plasma physics, Czech Republic

bInstitute of Physics of the Czech Academy of Sciences, Czech Republic

cFaculty of Mechanical Engineering, Czech Technical University in Prague, Czech Republic

dMathematics and physics faculty, Charles University in Prague, Czech Republic

lukac@ipp.cas.cz

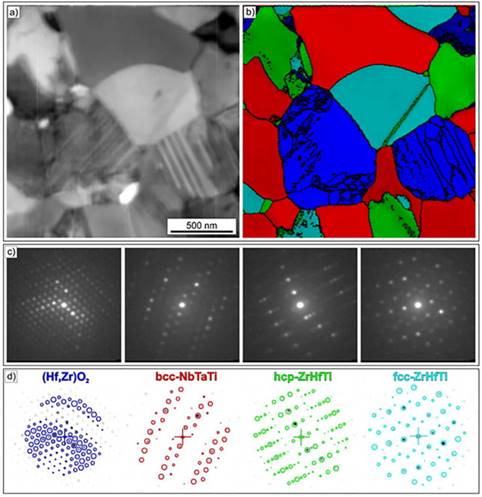

Spark plasma sintering (SPS) is a well-recognized method in powder metallurgy which produces ultra fine grained materials with outstanding properties. Short times are sufficient for mutual appliance of pressure and temperature during powder sintering and simultaneously the grain growth is significantly reduced. This highly depends on the homogeneity, purity and size distribution of powder feedstock. In our study, high energy milling in various atmospheres was used to prepare HfNbTaTiZr powders and phase composition of sintered materials was investigated providing huge impact on material properties. It was found to be the formation of very fine microstructure of interconnected BCC phase and unexpected FCC phase, see Figure 1. Detailed TEM investigation revealed that the formation of ZrHfTi-rich oxo-nitrites has taken place during sintering of powders milled in air or in oxygen atmosphere [1]. Correlation of oxygen and nitrogen content with FCC phase volume was investigated. The Rietveld refinement analysis coupled with whole powder pattern modelling was performed. It provided the essential information about the phase fractions and stoichiometry of ZrHfTi(O,N)x complexes. Promising mechanical properties like very high hardness and high temperature wear resistance were tested.

Figure 1. ACOM phase mapping. a) virtual BF image, b) phase map, c) experimental diffraction patterns (DP) and d) DPs overlaid with matching templates of the respective phases.

1. Lukáč, F et al.: The origin and the effect of the fcc phase in sintered HfNbTaTiZr, Materials Letters, 286, (2021), 129224, https://doi.org/10.1016/j.matlet.2020.129224

This project is suuported by Czech Science Foundation grant no. 22-24563S