Residual stresses, strain, morphology and orientation relation in Cr and Mo layers deposited on various substrates

Petr Cejpek, David Rafaja, Mykhaylo Motylenko, Christian Schimpf, Astrid Leuteritz, Shail Shah

Institute of Materials Science, TU Bergakademie Freiberg, Gustav-Zeuner-Str. 5, 09599 Freiberg, Germany

The study presented here is a part of the project focused on the fundamental description of the laser ablation process. The laser ablation could introduce craters into a material which can play an important role in a modification of local material properties, especially microstructure. The microstructural properties inside the craters could then work as post mortem probes of condition (temperature, pressure) during ablation itself.

However, to describe these microstructural changes properly, well known original state of a material is the necessary prerequisite. For this purpose, the 100 nm thick epitaxial layers of Cr and Mo were deposited by magnetron physical vapour deposition (PVD) on various substrates: amorphous SiO2 and single-crystalline MgO(100), MgO(110) and corundum Al2O3(0001). The microstructural properties such as residual stresses, grain sizes, layer morphology and crystallographic orientation have been studied in the mean of the X-ray diffraction and electron microscopy.

With the use of an amorphous substrate SiO2, both Cr and Mo layer grows with the 110 fibre texture. Here, the surface energy plays the decisive role, which is the lowest at 110 crystallographic plane (Cr and Mo are both bcc metals).

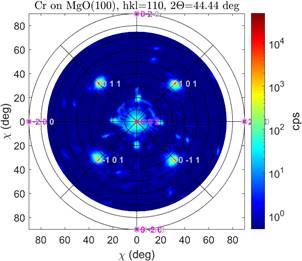

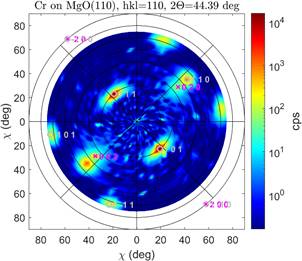

Using a single crystalline substrate, the minimalization of the deformation energy leading from the lattice misfit between the layer and substrate will play an important role. Therefore, deposited layers will grow in the specific orientation relation with the substrate. However, a presence of several variants with different orientation was observed in some cases. Individual orientation relations were deduced from the measured pole figures (example in Figure 1a and 1b) and are shown in Table 1.

The residual stresses obtained by sin2ψ

method are shown in Table 1. The results show, that the layers

posses quite high residual stresses in the order of several GPa.

In comparison to the yield strength (0.131 GPa for Cr and

0.324 GPa for Mo [1]), this points to a fact that there should be an

inner mechanism leading to the material hardening. The analysis of the diffraction

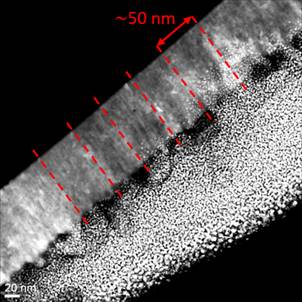

peaks broadening and also transmission electron microscopy show that the

deposited layers consist of the small columnar crystallites with the size of d = 20-50 nm

(see Figure 1c). The presence of such crystallites leads to an increase

of the yield strength through the Hall-Petch relation ![]() [2].

[2].

Table 1: Out-of-plane orientation of studied layers and their residual lateral stress σlat.

|

|

substrate |

|||||||

|

MgO(100) |

MgO(110) |

Al2O3(0001) |

||||||

|

out-of-plane orientation |

σlat (GPa) |

out-of-plane orientation |

σlat (GPa) |

out-of-plane orientation |

σlat (GPa) |

|||

|

layer |

Cr |

100 |

1,4 |

Twins with 211 |

4,2 |

unspecific fibre texture |

- |

|

|

Mo |

100 and 2 variants with 110 (Δϕ=90°) |

-1,5 -0,8 -0,8 |

Twins with 211 |

3,5 |

3 variants with 110 (Δϕ=60°) |

1,5 |

||

a) b)

c)