Abnormal crystallite grains in twined ScN/MgO thin films

E. de Prado, J. Duchoň, J. More Chevalier, S. Cichoň, L. Fekete. J. Lančok

FZU-Institute of Physics of the Czech Academy of Sciences, Na Slovance 2, 18200 Praha 8, Czechia

prado@fzu.cz

Rock-salt-structured scandium nitride thin films are of high interest in material science due to their physical properties such as high melting point and high electron mobility [1-3]. It has been demonstrated that the presence of defects and impurities affects thermoelectric properties [4]. Planar defects, such as twins, have been reported for ScN thin films grown with different orientations. While the (111) oriented films have been thoroughly studied [5,6], the (001) and (001)+(111) bi-oriented cases still lack comprehensive research. Furthermore, larger defects, such as abnormally oriented grains (AOGs), were widely analyzed for the ternary ScxAl1-xN fims [7-10], but their presence in pure ScN films has not been fully studied yet.

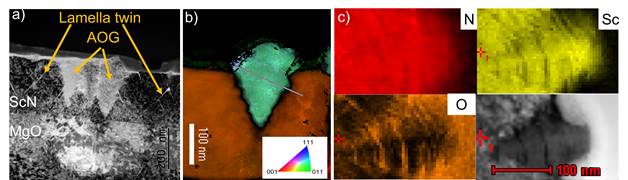

In this work, we fill the gap and present the study of the AOGs in (001) and (111)+(001) bi-oriented twinned ScN films deposited on MgO (001) substrates by DC reactive magnetron sputtering. Transmission electron microscopy (TEM) measurements confirmed the presence of twin lamellas of several nanometers (3-6 nm) thickness and also revealed that some of the AOGs are growing from the twins present in the films. In addition, energy-dispersive X-ray spectroscopy (EDX) measurements indicated increased concentration of oxygen around these AOGs, which is of great importance since the presence of oxygen defects affects the ScN films properties [11].

Figure 1: TEM measurements for the (001) oriented ScN film. a) Bright field image showing the abnormal oriented grains (AOGs) and lamella twins; b) ASTAR-TEM orientation map; c) EDX performed around one AOG.

1. D. Gall, I. Petrov, N. Hellgren, L. Hultman, J.E. Sundgren, J.E. Greene, J. Appl. Phys, 84 (1998), pp. 6034–6041.

2. A.R. Smith, H.A.H. AL-Brithen, D.C. Ingram, D. Gall, J. Appl. Phys, 90 (2001), pp. 1809–1816.

3. J.P. Dismukes, W.M. Yim, V.S. Ban, J. Cryst. Grow. 13-14, (1972), pp. 365–370.

4. S. Kerdsongpanya, B. Alling, and P. Eklund, Phys. Rev. B, 86, (2012), 195140.

5. M. A. Moram, T. B. Joyce, P. R. Chalker, Z. H. Barber, and C. J. Humphreys, Appl. Surf. Sci., 252 (2006), pp. 8385–8387.

6. S. Acharya, A. Chatterjee, V. Bhatia, A.I.K. Pillai, M. Garbrecht, B. Saha, Mater. Res. Bull., 143, (2021), 111443.

7. C. S. Sandu, F. Parsapour, S. Mertin, V. Pashchenko, R. Matloub, T. LaGrange, B. Heinz, P. Muralt Phys. Status Solidi A, 216, (2019), 1800569 .

8. M. Li, K. Hu, H. Lin, and Y. Zhu, IEEE Int. Ultrason. Symp. (2021).

9. M. Li, J. Xie, B. Chen, N. Wang, and Y. Zhu, IEEE Int. Ultrason. Symp. (2019), pp. 1124–1126.

10. C. Liu, M. Li, B. Chen, Y. Zhang, Y. Zhu, and N. Wang, J. Micromech. Microeng. 32, (2022), 034002.

11. J. More-Chevalier, U.D. Wdowik, D. Legut, S. Cichoň, E. de Prado, I. Gregora, J. Bulíř, M. Novotný, L. Fekete, J. Lančok, Appl. Surf. Sci., 615, (2023), 156203 .

The work has been supported by the Ministry of Education, Youth and Sports, Czech Republic, project no. SOLID21CZ.02.1.01/0.0/0.0/16_019/0000760. Authors acknowledge Petr Svora for the preparation of the lamellas.