Metastable aluminas in plasma sprayed coatings

F. Lukáč1,2, R. Mušálek1, T. Tesař1, Jan Medřický1, Jonáš Dudík1,3

1Institute of Plasma Physics of the Czech Academy of Sciences, Za Slovankou 3, 182 00, Prague 8, Czech Republic

2Faculty of Mathematics and Physics, Charles University in Prague, V Holešovičkách 2, 180 00, Prague 8, Czech Republic

3Faculty of Nuclear Sciences and Physical Engineering, Czech Technical University in Prague, Trojanova 13, 120 01 Prague, Czech Republic

email: lukac@ipp.cas.cz

Plasma sprayed coatings are materials with history of extreme thermal conditions. Very fine ceramic powder particles are carried by gas into high enthalpy plasma stream generated by plasma torch and molten droplets are projected onto cooled substrate. Solidified splats of added material are being layered and become a heat-sink for next incoming overheated liquid droplets. Therefore, interesting chemical compounds may be formed on the interface between splats despite high cooling rate. Moreover, recent advances in plasma technology enable injection of secondary material into the plasma torch by feeding of liquid suspension or solution. Using ethanol or water carriers influences already harsh conditions and new parameters of freedom for tailoring of coatings are available. Recently, we utilized hybrid plasma spraying process by simultaneously feeding the plasma stream with both powder and liquid feedstocks [1]. Very fine splats formed from liquid precursors may act as a cohesion improving agent for better durability of coatings.

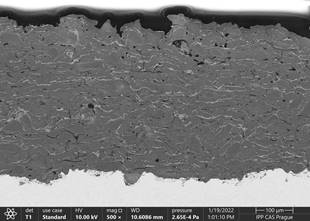

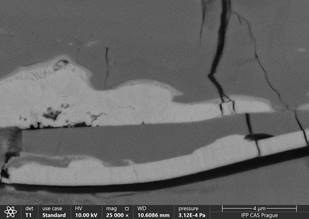

Figure 1 shows an example of hybrid coating sprayed from Al2O3 powder and a water based TiO2 suspension. At the interface of splats between alumina and titania, the newly formed Al2TiO5 phase was identified. However, only on the upper interfaces where the large alumina droplet interacted with already deposited miniature TiO2 and the interdiffusion happened. Figure 2 shows the X-ray diffractogram of such coating. Major part of peaks intensity is in metastable phases d and g-Al2O3 whose defected spinel structure is still not well describable by Rietveld refinement fitting. Therefore, combination of standards of powder deposited coatings with XRF method is necessary to achieve accurate phase ratios.

|

|

Figure 1. Micrographs of plasma sprayed coating of Al2O3 fed as a powder (dark) and TiO2 fed as a liquid suspension (white). Interface between splats shows formed Al2TiO5 phase formed during cooling process.

|

Figure 2. Micrographs of plasma sprayed coating of Al2O3 fed as a powder (dark) and TiO2 fed as a liquid suspension (wihte). Interface between splats shows formed Al2TiO5 phase formed during cooling process.

1. R. Musalek, T. Tesar, J. Dudik, J. Medricky, J. Cech, F. Lukac, J Therm Spray Tech (2022).

Authors would like to acknowledge the financial support from the Grant Agency of Czech Republic by project 22-21478S.