Line profile analysis and rocking curve evaluation of 3D diffraction data

Gergely Farkas1, Jishnu Bhattacharyya2, Gyula Zilahi3, Kristián Máthis4, Sean R. Agnew5

1Nuclear Physics Institute of

the CAS, Řež, Czech Republic

2University of Virginia, Charlottesville, USA

3D UK Atomic Energy Authority, Oxfordshire, United Kingdom

4Department of Physics of Materials, Charles University, Prague,

Czech Republic

afarkas@ujf.cas.cz

Diffraction patterns from ~100 individual grains of a solutionized and quenched metastable β-Ti alloy were obtained by high energy synchrotron diffraction during in-situ tensile deformation experiments. The diffraction patterns of select grains were analyzed per an established single-crystal line profile analysis technique to assess the dislocation density evolution on individual slip systems. Further, a new technique to estimate the geometrically necessary dislocation (GND) density from rocking curves is introduced. The results provide a powerful complement to previously published comparisons between measured and crystal plasticity simulated internal elastic strains (and stresses). In particular, they reveal there is no preference for ½<111> Burgers vector dislocations to reside on a particular glide plane, since they have similar densities on {110} and {112} planes. In addition, an explanation for the observation of strain softening in some of the grains is hypothesized as form of “plastic buckling.” A select number of strain softening grains exhibit higher lattice curvature (GND density) than other grains, indicating that the grains have “broken up” into smaller domains which are deforming in distinct ways from one another, and more easily than they would have together.

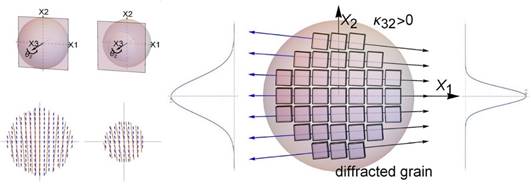

Figure 1. Rocking curve broadening vs grain curvature