Studies of precipitation in engineering materials using small-angle neutron scattering

V. Ryukhtin1, P. Strunz1, A. B. Yildiz2, P. Beran1,3, S. Bakardjieva4

1 Nuclear Physics Institute ASCR, v.v.i., Øež, Czech Republic

2Department of Materials Science and Engineering, KTH Royal Institute of Technology, SE-100 44 Stockholm, Sweden

3ESS ERIC, Lund, Sweden

47Institute of Inorganic Chemistry CAS, 250 68 Husinec-Øež, Czech Republic

ryukhtin@ujf.cas.cz

Precipitations microstructure in alloys is strongly connected with their physical properties such as hardness or ductility. Usually, conventional methods of electron microscopy are used for assessing the morphological characteristics of the precipitates. Nevertheless, in some cases, the small-angle neutron scattering (SANS) technique can be more efficient due to its unique abilities. Here, we would like to demonstrate few examples.

Influence of copper on precipitations during aging was studied in medium carbon spring steel [1]. It was found that alloying by copper significantly improves material characteristics (increases yield stress, increases corrosion resistance, causes “self-healing” of ultrafine cracks). Magnetic SANS (MSANS) was used for accurate characterization of nanosized copper particles nucleated by tempering at 400-500°C. In this case, MSANS was very effective and, potentially, it can be used for in-situ study of Cu precipitation kinetics in similar alloys.

Another example is investigation of sintering of composite tungsten (W) grains in cobalt (Co) binder. In vanadium-doped tungsten carbide (WC) − Co composite material system, in-situ and ex-situ SANS and ultra-small-angle neutron scattering (USANS) experiments helped to explain how additions of vanadium (V) affect the nano- and microstructure during sintering, and result in smaller WC grains [2]. Whereas SANS quantified the nano-scale interfacial layers responsible of grain coarsening inhibition, USANS was applied to study microstructural refinement.

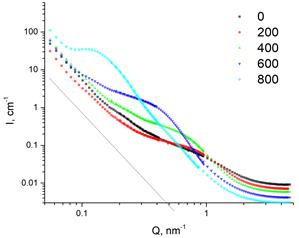

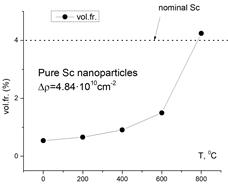

SANS was also applied for the investigation of the Sc-doped TiO2 anatase as material for photocatalysis [3]. Growth of Sc precipitations was observed with increasing aging temperature due to its expelling from anatase crystallites. It was showed by SANS with agreement of jointly refined neutron and X-rays diffraction data, that entire scandium content at aging temperature above 800°C was driven out of grains and formed particles at TiO2 grain boundaries.

a)

a) b)

b)

Figure 1. SANS data of Sc-doped TiO2 aged at temperatures (a) and fitted volume fraction of Sc precipitates from corresponded SANS data (b)

1. A. Gokhman, Z. Nový, P. Salvetr, V. Ryukhtin, P. Strunz, P. Motyèka, J. Zmeko, J. Kotous, Materials, 14, (2001) 1445.

2. A. B. Yildiz, J. Weidow, V. Ryukhtin, S. Norgrend, G. Wahnström, P. Hedström, Scripta Mat. 173, (2019) 106-109.

3. S. Bakardjieva, J. Mares, E. Koci, J. Tolasz, R. Fajgar, V. Ryukhtin, M. Klementova, Š. Michna, H. Bibova, R. Holmestad, R. Titorenkova, M. Caplovicova, Nanomaterials, 12, (2022) 750.

V. Ryukhtin and P. Strunz acknowledge partial support from the long-term conceptual development project RVO 61389005 of the Nuclear Physics Institute of the Czech Academy of Sciences and from the Czech Academy of Sciences in the frame of the program “Strategie AV21, No. 23”. USANS measurements were conducted at CANAM infrastructure supported by MŠMT projects LM2015056 and LM2018120. V. Ryukhtin acknowledges beamtime at V4 SANS facility granted by HZB.