Structural analysis of nanoporous gold obtain by dealloying

Adrien Chauvin1, Lukas Horak1, Elen Duverger-Nédellec1, Milan Dopita1, Pierre-Yves Tessier2, and Abdel-Aziz El Mel2

1Charles University in Prague, Ke Karlovu 3, 121 16 Praha 2, Czech Republic

2Institut des Matériaux Jean Rouxel, Université de Nantes, CNRS, 2 rue de la Houssinière B.P. 32229, 44322 Nantes cedex 3, France

andrien.chauvin@karlov.mff.cuni.cz

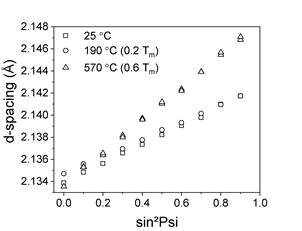

Nanoporous materials are of great interest since a few decades due to their high specific surface area and their three-dimensional porosity. These materials, constituted of interconnected ligament structure, can be used in a wide range of areas such as biotechnology [1], electronics [2] or energy storage [3]. The most used technique for the creation of a nanoporous structure is the dealloying process. Briefly, it consists in the dissolution of the less noble metal from an alloy resulting in the formation of a three-dimensional skeleton of the more noble element at nanoscale. Nowadays, lots of work has been devoted to tune the final nanoporous structures, i.e. ligament sizes and porosity, and improve their properties. These techniques include, for example, the modification of the dealloying kinetic or by further annealing the nanoporous structure. However, only a few studies report on the modification of the morphology of as-grown alloy. Indeed, controlling the morphology and the residual stress in thin films after the growth of materials is crucial to tailor their properties. Although the presence of residual stress in a thin film is in general considered as a drawback, however in some particular cases, it can be of real benefit for the desired application. In this contribution, I will show how the residual stress in a deposited gold copper alloy by magnetron co-sputtering can be used to tune the morphology of nanoporous gold after dealloying. Deposition of a gold copper thin film was performed over a substrate at different temperature leading to different morphologies of the thin film according to Thornton diagram. Dealloying those thin films in nitric acid lead to an island-like nanoporous morphology for high deposition temperature. The origin of such innovative morphology is attributed to the remaining stress in the sample after deposition (Figure 1). More precisely, it has been demonstrated that the residual stress is mostly due to the thermal stress induced during deposition. In this study, the remaining stress in as-grown films was studied by X-ray diffraction analysis and the nanoporous structure was probed by Small Angle X-ray Scattering and Scanning Electronic Microscopy. Such nanostructured gold thin film with a double level of porosity can be considered as potential candidates for the development of advanced sensors and actuators.

Figure 1. Evolution of the d-spacing as a function of sin2Ψ in as-grown thin film at different temperatures.

1. W. Gao and J. Wang, Nanoscale, 6, (2014), 10486.

2. A. Chauvin, W. Txia Cha Heu, J. Buh, P.-Y. Tessier and A.-A. El Mel, NPJ Flexible Electronics, 3, (2019).

3. X. Lang, A. Hirata, T. Fujita and M. Chen, Nature Nanotechnology, 6, (2011), 232.

The authors acknowledge the financial support from the project NanoCent—Nanomaterials Centre for Advanced Applications, Project No. CZ.02.1.01/0.0/0.0/15_003/0000485, financed by ERDF.