Thermally induced changes in modulated structure of 10M Ni50Mn27Ga22Fe1 martensite

P. Veøtát1,2, L. Straka2,3, O. Pacherová2, M. Klicpera3, A. Sozinov4, O. Heczko2

1 Faculty of Nuclear Sciences and Physical Engineering, Czech Technical University in Prague, Prague, 11519, Czech Republic.

2 Institute of Physics, Czech Academy of Sciences, Prague, 18221, Czech Republic.

3 Faculty of Mathematics and Physics, Charles University, Prague 2, 12116, Czech Republic.

4 Material Physics Laboratory, LUT University, Lappeenranta, 53850, Finland.

vertat@fzu.cz

The observation of magnetic shape memory (MSM) effect in Heusler alloy Ni2MnGa by Kari Ullakko [1] stimulated tremendous scientific interest in this class of materials. The MSM alloys possess many practical applications in sensors [2], actuators [3, 4], micropumps [5] and energy-conversion devices [6]. From the fundamental point of view, the MSM effect includes the magnetically induced thermoelastic martensitic transformation and magnetically induced structural reorientation of martensite, where the extremely mobile twin boundaries of martensite play and essential role.

The structure of martensite of the Ni-Mn-Ga-based alloys is often modulated, depending on composition and temperature. Although the modulated structure is decisive in the aforementioned extremely mobile twin boundaries of Ni-Mn-Ga alloys, the character of modulation is still under discussion – especially for the 10M modulated martensite, for which the highest twin boundary mobility is found. For different compositions, the "10M martensite" was reported to have commensurate or incommensurate modulation [7-10] or to be nanotwinned [11, 12]. Both incommensurate and nanotwinned structure can result in similar apparent changes in modulation vector. Considering the incommensurality approach, it has been shown that the modulation vector changes gradually with temperature [7, 9].

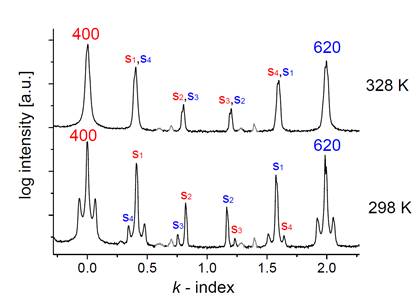

Using neutron and X-ray diffraction on single crystal of Ni50Mn27Ga22Fe1 alloy, we discovered transition between commensurate and incommensurate modulated structure with changing temperature (Fig. 1) and followed its evolution in 10M martensite. We observed that doping of the Ni-Mn-Ga alloy with Fe leads to accentuation of the modulation satellites and it also leads to shifting of the temperature ranges of occurrence of different martensites, which is likely favourable for the applications.

We found that the discovered transition exhibits thermal hysteresis around the room temperature. Owing to the hysteresis, sample can be prepared in commensurate or incommensurate state at the same temperature using appropriate heating/cooling procedure. Observed transition was confirmed by resistivity measurements and by scanning electron microscopy. The investigation whether the incommensurality is proper or only apparent caused by nanotwinning is the subject of ongoing research.

Figure 1. Measured q-scans in the [110] direction of the reciprocal space. At 298 K, the measurement indicates incommensurate 10M modulated martensite. Upon heating to 328 K, the structure transforms to commensurate 10M. Modulation satellites belonging to 400 and 620 reflections are marked red and blue. The slight splitting of the peaks is caused by the mosaicity of the crystal and a/b twinning. Reflections from the sample holder are marked grey.

1. K. Ullakko, J. K. Huang, C. Kantner, R. C. O’Handley, V. V. Kokorin, Applied Physics Letters, 69, (1996), 1966.

2. J. M. Stephan, E. Pagounis, M. Laufenberg, O. Paul, P. Ruther, IEEE Sensors Journal, 11, (2011), 2683.

3. R. C. O’Handley, K. Ullakko, High-strain, magnetic field-controlled actuator materials, US patent US5958154A, 1997.

4. J. Tellinen, I. Suorsa, A. Jääskeläinen, I. Aaltio, K. Ullakko, in Proceedings of the 7th International Conference on New Actuators, Actuator 2002, Bremen, Germany, edited by H. Borgmann, 2002, pp. 566-569.

5. A. R. Smith, D. Fologea, P. Müllner, in Proceedings of the 18th International Conference on New Actuators, Actuator 2008, Bremen, Germany, edited by H. Borgmann, 2018.

6. N. M. Bruno, C. Ciocanel, H. P. Feigenbaum, A. Waldauer, Smart Materials and Structures, 21, (2012), 094018.

7. L. Righi, F. Albertini, A. Paoluzi, S. Fabbrici, E. Villa, G. Calestani, S. Besseghini, Materials Science Forum, 635, (2010), 33.

8. T. Fukuda, H. Kushida, M. Todai, T. Kakeshita, H. Mori, Scripta Materialia, 61, (2009), 473.

9. A. Çakir, M. Acet, L. Righi, F. Albertini, M. Farle, AIP Advances, 5, (2015), 097222.

10. S. O. Mariager, T. Huber, G. Ingold, Acta Materialia, 66, (2014), 192.

11. S. Kaufman, U. K. Rößler, O. Heczko, M. Wuttig, J. Buschbeck, L. Schultz, S. Fähler, Physical Review Letters, 104, (2010), 1457029.

12. L. Straka, J. Drahokoupil, P. Veøtát, M. Zelený, J. Kopeèek, A. Sozinov, O. Heczko, Scientific Reports, 8 (2018), 11943.

This work was supported by the Grant Agency of the Czech Technical University in Prague, grant No. SGS19/190/OHK4/3T/14.