Application of powder X-ray diffraction for heavy mineral prospection in the Czech Republic

M. Čurda, F. Laufek, T. Sidorinová, M. Štrba

Czech Geological Survey, Geologická 6, 152 00 Praha

michal.curda@geology.cz

The government of the Czech Republic has adopted a resolution no. 717 concerning the economic interests of the Czech Republic in the area of super strategic minerals resources and other minerals resources. Consequently, the state company DIAMO and the Czech Geological Survey were charged with a task to perform the evaluation and an update of strategic minerals resources of the Czech Republic [1].

A regional prospection for heavy minerals (i.e. minerals with density higher than 2.9 g/cm3) is an integral part of this project. This activity involves collection of selected samples in the field, mineral separation and subsequent quantitative phase identification. Traditionally, optical identification of separated mineral grains using binocular microscopes has been the most used method for such task. However, this method has several disadvantages, e.g. difficulties in identification of some mineral phases, high-time demands and others. Moreover, only well-qualified and experienced analyst can produce reliable results.

Another way of quantitative phase analysis of heavy minerals is an application of so-called automated mineralogy methods. Automated mineralogy analytical solutions are characterised by integrating largely automated measurement techniques based on Scanning Electron Microscopy (SEM) and Energy-dispersive X-ray spectroscopy (EDS). In addition to the quantitative phase analysis, this method can provide information concerning the size and shape of analysed grains, relations between minerals (e.g. their intergrowns) [3].Nevertheless, there are several disadvantages including e.g. the difficulty to distinguish between mineral polymorphs (e.g. TiO2 or Al2SiO5 polymorphs) or complex preparation of studied samples. The price of such analysis is also relatively high, which complicates its routine application.

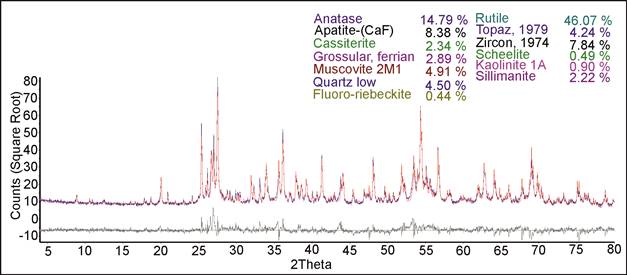

Powder X-ray diffraction (PXRD) with subsequent Rietveld data analysis seems to be an effective alternative method for such task. Preliminary analyses were performed at Laboratory of X-ray Diffraction of the Czech Geological Survey at Bruker D8 Advance diffractometer. The CuKα radiation, positive-sensitive detector Lynx Eye XE and 9-position sample changer (Flipstick) for reflection were used for measurement. Application of fast positive-sensitive detector and sample changer enabled fast data collection and high output from the Laboratory including automated nights measurements. Using the above-mentioned instrumentation, it is possible to measure 18 samples per day. Contrary to the methods of automated mineralogy, it is possible to distinguish between different polymorphs and the preparation of samples is relatively easy. On the other hand, a careful mineral separation of heavy minerals sample into several concentrates is necessary. Prior to diffraction analyses, the heavy minerals samples are separated according to their specific gravity and magnetic properties. The resulted fractions are weighted and subsequently analysed by PXRD. Qualitative analysis is performed in the HighScore program, subsequent quantitative analysis is carried out by the Rietveld method. A program Topas 5 is used.

In this contribution, fist experiences and preliminary results of quantitative phase analysis of heavy minerals concentrates by PXRD will be discussed. It seems that PXRD might be an interesting method for such a mineralogical analysis.

Figure 1. Typical Rietveld plot of the heavy mineral concentrate showing wt.% of minerals.