X-ray diffraction analysis of epitaxial layers with depth-dependent composition

E. Dobročka

Institute of Electrical

Engineering, Slovak Academy of Sciences, Dúbravská cesta 9,841 04 Bratislava, Slovak Republic

edmund.dobrocka@savba.sk

High

resolution mode is a special branch of X-ray diffraction techniques devoted to

the analysis of single crystalline epitaxial layers. One of the most important

tasks in epitaxial technologies is the determination of the layer composition.

For epitaxial systems with high degree of perfection, e. g. Si- or GaAs-based

compounds, the recorded diffraction curves have rather complex form and the

layer parameters are routinely determined by computer simulation of the model

structure. For epitaxial layers based on materials with lower quality and/or

larger lattice mismatch, the fine features of the diffraction curves are

missing and only more or less separated diffraction maxima of individual layers

can be observed. Typical examples of such materials are the

III–nitride semiconductors as AlN, GaN, InN and their ternary alloys. These materials

have great potential for use in optoelectronic and high-temperature electronic

devices due to their wide range of bandgaps and high-temperature stability [1-3].

If the layers are perfectly matched to the substrate,

it is sufficient the measuring of one symmetric

diffraction of the type ![]() . But in

the case of layers exhibiting certain degree of relaxation, in addition to the

symmetric diffraction, at least one asymmetric diffraction has

to be measured. From the position of the diffraction spots the

composition as well as the degree of relaxation can be determined. For the GaN based compounds the most convenient and accessible

asymmetric diffraction is

. But in

the case of layers exhibiting certain degree of relaxation, in addition to the

symmetric diffraction, at least one asymmetric diffraction has

to be measured. From the position of the diffraction spots the

composition as well as the degree of relaxation can be determined. For the GaN based compounds the most convenient and accessible

asymmetric diffraction is ![]() . There

are six equivalent diffractions of this type in hexagonal materials but if the

lattice tilting does not take place, it is, in principle, sufficient to measure

only one of these diffractions. However, measuring of several diffractions

increases the precision of the evaluation. Further simplification stems from

the symmetry of the stress state of the layer. Hexagonal c-oriented epitaxial

layers are transversely isotropic, i.e. the deformation of the layer is

completely described by two nonzero strain components:

. There

are six equivalent diffractions of this type in hexagonal materials but if the

lattice tilting does not take place, it is, in principle, sufficient to measure

only one of these diffractions. However, measuring of several diffractions

increases the precision of the evaluation. Further simplification stems from

the symmetry of the stress state of the layer. Hexagonal c-oriented epitaxial

layers are transversely isotropic, i.e. the deformation of the layer is

completely described by two nonzero strain components:

|

|

(1) |

where ![]()

![]() and

and ![]() ,

, ![]() are the lattice parameters of strained (and

measured) and fully relaxed layer, respectively [4]. These components are

connected by the relation

are the lattice parameters of strained (and

measured) and fully relaxed layer, respectively [4]. These components are

connected by the relation

|

|

(2) |

where ![]() and

and ![]() are the composition dependent stiffness constants

of the material. Alternatively,

instead of in-plane strain

are the composition dependent stiffness constants

of the material. Alternatively,

instead of in-plane strain ![]() , the degree of relaxation

, the degree of relaxation ![]() defined as

defined as

|

|

(3) |

is often used to describe the strain state of the

epitaxial layer. It has to be pointed out that the parameter ![]() characterizes the strain state of the layer

with respect to the substrate lattice.

characterizes the strain state of the layer

with respect to the substrate lattice.

The values of ![]() and

and ![]() can be calculated from the reciprocal

co-ordinates

can be calculated from the reciprocal

co-ordinates ![]() and

and ![]() of the layer diffraction spot

of the layer diffraction spot ![]() as [5]

as [5]

|

|

(4) |

The unknown composition parameter ![]() and the in-plane strain

and the in-plane strain ![]() can be obtained by solving the system of

equations in (1) and (2). A simple iterative procedure that

uses

can be obtained by solving the system of

equations in (1) and (2). A simple iterative procedure that

uses ![]() and

and ![]() in (4) as input parameters is outlined in [6].

The method supposes linear dependence of the parameters

in (4) as input parameters is outlined in [6].

The method supposes linear dependence of the parameters ![]() ,

,

![]() and

and ![]() ,

,

![]() on the composition

on the composition ![]() .

.

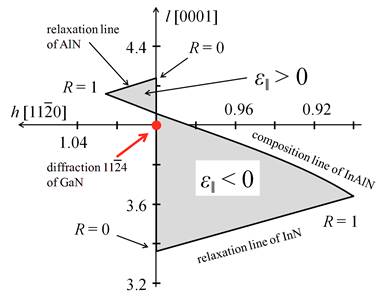

The complete information on the state of the epitaxial

layer can be obtained by measuring the reciprocal space map (RSM) around a

suitable asymmetric diffraction. For the later purposes it is reasonable to

introduce the presentation of the admissible positions of the layer spots in

reciprocal space in dependence of the layer composition and the degree of

relaxation. It follows from simple geometrical considerations that in the case

of AlGaN/GaN and InGaN/GaN systems the possible positions of the layer

diffraction spot are confined to triangular region in the vicinity of GaN

diffraction. This area is bounded by the so called relaxation line connecting

the AlN or InN layer diffraction spots for fully strained and completely

relaxed state [7]. The third vertex of the triangle is the GaN substrate (or

buffer layer) diffraction spot. However, for the system InAlN/GaN this area

comprises two triangular regions as shown in Fig. 1. This is a consequence of

the fact that the lattice parameters of GaN are in between the parameters of

InN and AlN lattices. The common vertex of these triangles corresponds to the

composition of the InxAl1-xN for which the layer is

perfectly matched to the GaN lattice. It is worth noting that this point in

reciprocal space does not coincide with the GaN diffraction spot. This is a

general property of hexagonal epitaxial systems and it stems from different

values of aspect ratios of InxAl1-xN and GaN lattice.

Figure 1. Schematic drawing

of the admissible positions of the  diffraction spot of InAlN

layer for various composition

diffraction spot of InAlN

layer for various composition  and degree of relaxation

and degree of relaxation  . Note the sign of the in-plane strain component

. Note the sign of the in-plane strain component  is opposite in Al rich and In

rich regions. For the sake of clarity the width of the area is 6-times

enlarged.

is opposite in Al rich and In

rich regions. For the sake of clarity the width of the area is 6-times

enlarged.

If InxAl1-xN layer is grown on GaN buffer

layer in sequence (without breaking the growth after GaN), unintentional

Ga-auto-incorporation into InxAl1-xN layer is an obvious problem, as

reported in [8-10]. Sources of Ga could be the deposited Ga-containing-residues

on the reactor wall, susceptor or shower head during GaN growth. Due to the

Ga-incorporation in InAlN, intended InxAl1-xN ternary alloy actually becomes

InxAlyGa1-x-yN quaternary

alloy. This has a significant consequence for the evaluation of X-ray

diffraction measurements, e. g. for the interpretation of the RSM. In the case

of ternary compounds each couple of lattice parameters a and c of

strained layer measured by X-ray diffraction has a unique solution ![]() ,

, ![]() ,

,

![]() and

and ![]() . Evidently,

this is not valid for quaternary compounds. In this case the composition of the

layer is described by two parameters, e. g. InxAlyGa1-x-yN,

and the measured values of strained lattice parameters

. Evidently,

this is not valid for quaternary compounds. In this case the composition of the

layer is described by two parameters, e. g. InxAlyGa1-x-yN,

and the measured values of strained lattice parameters ![]() and

and ![]() can be interpreted by an infinite number of

can be interpreted by an infinite number of ![]() ,

, ![]() values resulting in different relaxed lattice

parameters

values resulting in different relaxed lattice

parameters ![]() ,

,

![]() and

different degree of in-plane strain

and

different degree of in-plane strain ![]() . As an illustration,

in Tab. 1 five different compositions of quaternary InxAlyGa1-x-yN

layer resulting in the same values of measured lattice parameters are listed.

. As an illustration,

in Tab. 1 five different compositions of quaternary InxAlyGa1-x-yN

layer resulting in the same values of measured lattice parameters are listed.

Table 1. Five compositions

of quaternary InxAlyGa1-x-yN layer for the same

values of measured lattice parameters and corresponding relaxed lattice parameters

![]() ,

, ![]() and in-plane strain component

and in-plane strain component ![]() .

.

|

Ga [%] |

In [%] |

Al [%] |

|

|

|

|

0.0 |

18.4 |

81.6 |

0.31898 |

0.51134 |

– 0.14 |

|

5.0 |

17.2 |

77.8 |

0.31884 |

0.51147 |

– 0.09 |

|

10.0 |

16.0 |

74.0 |

0.31870 |

0.51160 |

– 0.05 |

|

15.0 |

14.7 |

70.3 |

0.31856 |

0.51173 |

– 0.006 |

|

20.0 |

13.5 |

66.5 |

0.31843 |

0.51187 |

0.04 |

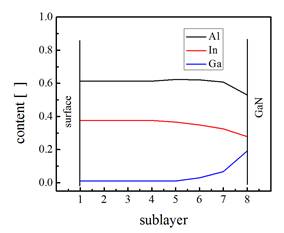

This example clearly demonstrates that in the case of

quaternary compounds the X-ray measurements alone are insufficient for the

determination of the layer composition and further independent analytical

technique is required for the evaluation of the structural parameters of the

layer. Moreover, the concentration of Ga atoms in the InxAl1-xN

layer is strongly dept-dependent with higher value at the bottom close to the

GaN buffer layer. The depth distribution of the elements in the quaternary

layer can be determined e. g. by Rutherford backscattering spectrometry (RBS),

X-ray photoelectron spectroscopy etc. An example of depth profile of the layer

composition obtained by RBS measurement is given in Fig. 2. It is seen that the

highest concentration, almost 20%, of Ga is at the bottom of the layer and from

the middle up to the layer surface the Ga content is negligible. The distance

between the adjacent sublayers is ~ 40 nm. The total layer thickness is ~280

nm. These measurements can be combined with the X-ray results in the way

outlined in the following.

|

|

|

Figure 2. Depth profile of InAlGaN layer composition. The distance between the adjacent sublayers is ~ 40 nm. |

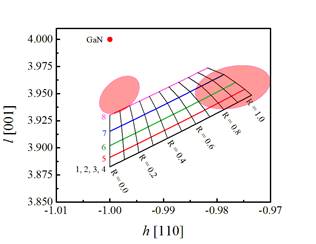

Figure 3. Composition & Relaxation diagram of InAlGaN layer. The position of two maxima revealed by X-ray RSM are schematically shown as ellipses. |

The data describing the depth distribution of the

elements in the layer are used as input parameters and the theoretical

relaxation lines are calculated for all sublayers with their particular composition

obtained by RBS analysis. The set of calculated relaxation lines plotted in

reciprocal space build up a special mesh – the composition & relaxation

diagram. Each relaxation line in this diagram is connected with a sublayer in

different depth, hence at favourable circumstances the eventual depth

distribution of the relaxation can be established simply by comparison of the

diagram with the measured RSM (not shown here). Such a comparison is given in

Fig. 3.

It is seen that in

addition to the basic GaN diffraction ![]() two distinct but rather broad maxima

corresponding to epitaxial layer were revealed. They are schematically depicted

in the diagram as transparent red ellipses. The curves of constant degree of

relaxation

two distinct but rather broad maxima

corresponding to epitaxial layer were revealed. They are schematically depicted

in the diagram as transparent red ellipses. The curves of constant degree of

relaxation ![]() are also shown. It can be concluded that the

InAlN layer with incorporated Ga atoms is apparently divided into two layers.

The maximum on the left side can be ascribed to the bottom layer with high Ga

content. The layer is almost perfectly matched to the GaN buffer layer. It is

also evident that the Ga content provided by RBS measurement is somewhat

underestimated, the maximum does not lie on the deepest relaxation line having

the highest Ga content. The right side maximum can be related to the upper

layer with negligible Ga content. The layer is almost fully relaxed.

are also shown. It can be concluded that the

InAlN layer with incorporated Ga atoms is apparently divided into two layers.

The maximum on the left side can be ascribed to the bottom layer with high Ga

content. The layer is almost perfectly matched to the GaN buffer layer. It is

also evident that the Ga content provided by RBS measurement is somewhat

underestimated, the maximum does not lie on the deepest relaxation line having

the highest Ga content. The right side maximum can be related to the upper

layer with negligible Ga content. The layer is almost fully relaxed.

1.

J. Kuzmík, IEEE

Electron Device Lett., 22,

(2001), 510.

2.

Y. Yue, Z. Hu, J. Guo, B. Sensale-Rodriguez, G.

Li, R. Wang, F. Faria, T. Fang, B. Song, X. Gao, IEEE Electron Device Lett., 33,

(2012), 988.

3.

J. Kuzmík, A.

Georgakilas, IEEE Trans. Electron Dev.,

58, (2011), 720.

4.

A. Krost, A. Dadgar, G.

Strassburger, R. Clos, phys. status solidi A, 200, (2003), 26.

5.

E. Dobročka, S.

Hasenöhrl, P. Chauhan, J. Kuzmík, Appl.

Surf. Sci. 461, (2018), 23.

6.

P. Chauhan, S.

Hasenöhrl, E. Dobročka, Ľ. Vančo, R. Stoklas, J. Kováč, P. Šiffalovič, J.

Kuzmík, Appl. Surf. Sci. 470, (2019), 1.

7.

U.

Pietsch, V. Holý, T. Baumbach, High-Resolution

X-Ray Scattering, second ed., Springer, New York, 2004.

8.

S. Choi, H. J. Kim, Z.

Lochner, J. Kim, R. D. Dupuis, A. M. Fischer, Yu. R. Juday, T. L. Huang, J. Y.

Huang, F. A. Ponce, J.-H. Ryou, J. Cryst.

Growth, 388, (2014), 137.

9.

J. Kim, Z. Lochner,

M.-H. Ji, S. Choi, H. J. Kim, J. S. Kim, R. D. Dupuis, A. M. Fischer, Yu. R.

Juday, T. L. Huang, J. Y. Huang, F. A. Ponce, J.-H. Ryou, J. Cryst. Growth, 388,

(2014), 143.

10.

M. Hiroki, Y. Oda, N.

Watanabe, N. Maeda, H. Yokoyama, K. Kumakura, H. Yamamoto, J. Cryst. Growth, 382,

(2013), 36.

The author gratefully

acknowledges S. Hasenöhrl for providing the

sample and D. Machajdík for RBS measurement.