In-situ SANS study of precipitates nanostructure of single crystal Ti-15Mo

V. Ryukhtin1, P. Strunz1, P. Kadletz1, P. Zhaňal2, U. Keiderling3, D. Wallacher3

1Nuclear Physics Institute v.v.i. ASCR, 250 68 Řež, Czech Republic

2Department of Physics of Materials, Charles University, Ke Karlovu 5, 12116 Prague, Czech Republic

3Helmholtz Zentrum Berlin for Materials and Energy, D-14109 Berlin, Germany

ryukhtin@ujf.cas.cz

Titanium alloys have plenty of applications in industry and medicine due to unique combination of high strength, low density, and excellent biocompatibility [1]. Ti-15Mo (in wt.%) is called β-stabilized binary alloy, it contains mostly β-phase (bcc) and also encloses metastable precipitates of ω (hexagonal) and α (hcp) phases [2]. Microstructure of the precipitates has great impact on mechanical properties and thermal stability of the alloy. Thanks to nanometres size of the precipitates and partitioning of molybdenum content in different phases small-angle neutron scattering (SANS) instrument can be effectively used for the in-situ investigation of this microstructure.

In the present studies SANS data were measured at three orientations of the single crystal sample – (111)β, (110)β and (100)β of β-phase with correspondent plane perpendicular to incident neutron beam direction. Samples were installed in vacuum high temperature furnace and heated with heating rates of 1 K/min from room temperature up to 600 0C. SANS data were recorded in so-called list-mode and afterwards binned by time frames of 5 minutes, which corresponds to temperature range of 5 K. The measured data were calibrated using water and corrected by standard measurements of cadmium background. Scattering of the sample in high temperature furnace was used as “buffer” background.

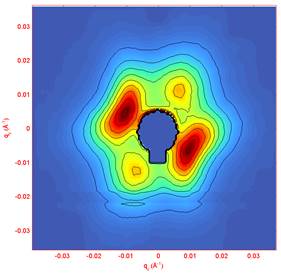

Figure 1. SANS pattern of Ti-15Mo sample in [100]β orientation for temperature range 410 0C ÷ 415 0C during in-situ measurements with 1 K/min heating rate.

2D pattern of SANS for sample orientation [100]β parallel to incident neutron beam at temperature range 410 0C ÷ 415 0C taken at sample-to-detector distance SD=12 m with collimated neutron beam of 5 Å (±0.5 Å) wavelength is shown in Figure 1. The observed reflexions are formed by interparticles structure factor, due to high ordering of ω-precipitates. This ordered microstructure exists in wide temperatures range (up to about 560 0C), however the reflexions were observed in limited Q-range due to fixed SD and wavelength of the instrument. With increasing of temperature positions of the peaks decrease. Mean interparticle distances obtained from peak positions and intensities for [110]β at SD=16 m is shown in Figure 2.

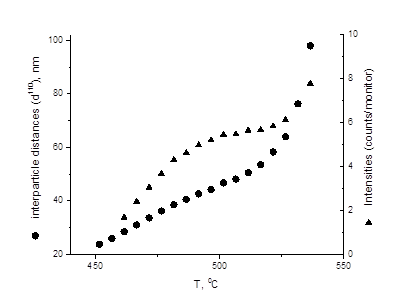

Figure 2. Interparticle distances (circles) and intensities (triangles) of peaks for [110]β sample orientation in dependence on sample temperature.

Observed spots at SANS patterns at temperatures lower than about 560 0C were formed by so-called isothermal ωiso precipitates. Symmetry of the interpaticles peaks corresponded to simple cubic ordering of the particles and basis axis are parallel to bcc axis of β-phase. Increasing of temperature leads to exponential growth of volume fraction of the ω precipitates and increasing of interparticle distance due to coalescence of smaller precipiates into larger ones.

Scattering from ωiso phase became invisible at maximum instrumental resolution (SD=16 m) after temperature exceeded 560 0C due to strong intensities from very long α particles. Time resolved SANS by cooling from 600 0C have showed that α precipitates structure do not change significantly and ωiso particles were not observed.

The presented investigations were supported by CSF project 14-36566G: Multidisciplinary research centre for advanced materials. Allocation of neutron beamtime at SANS instrument V4 is acknowledged to HZB.

1. Lutjering G, Williams JC (2007) Titanium. Engineering materials, processes. Springer, Berlin, pp 1–39. doi:10.1007/978-3-540-73036-1.

2. B.S. Hickman, The Formation of Omega Phase in Titanium and Zirconium Alloys: A Review J. Mater. Sci. 4 (6) (1969) 554.