Structure Evaluation of Dual Phase Steels by EBSD Method

M. Černík, R. Gburík, I. Kohútek, P. Vranec,

U.S.Steel Košice, s.r.o., Vstupný areál U.S. Steel, 044 54 Košice

mcernik@sk.uss.com, rgburik@sk.uss.com, ikohutek@sk.uss.com, pvranec@sk.uss.com

For the development of new steel grades, it is necessary to know the microstructure and texture of rolled steel substrate because every technological process forms specific microstructure and texture of the material. Laboratory diffraction methods XRD (X-ray diffraction) and EBSD (Electron Back-Scattered Diffraction) are suitable for the knowledge of microstructure and texture. Both methods describe the texture in the form of pole figures, orientation distribution function (ODF) and selected texture fibers. Texture is very important for the materials with high anisotropy. For the dual phase (DP) steels the microstructure is more important. The content of retained austenite and martensite fraction in the ferrite are parameters which define the steel properties. For the DP steels with hardness of 1000 MPa the amount of austenite was measured at 6%. The most precise and efficient measurement of austenite is by means of XRD. The sample is polished and for the inhibition of anisotropy, the sample rotates during the measurement. Determination of austenite content was not done precisely by means of EBSD as the measurement is highly dependent on the perfect sample preparation for the measurement.

However, EBSD method provides many advantages which are not provided by classical optical microscopy methods of microstructure investigation. This includes many parameters, i.e. image quality (IQ) map, inverse pole figure (IPF), grain average misorientation (GAM), kernel average misorientation (KAM), geometrically necessary dislocations (GND), grain size and others. All these parameters comprehensively describe the microstructure of DP steels. IQ parameter is very important for the determination of martensite fraction. This parameter makes provision for distortion of the lattice, therefore it is very suitable to determine the martensite fraction, what is used by many authors [1]. This method was also used by K. Radwanski [2] for the determination of the deformed ferrite fraction. The martensite content can be also calculated from fitted XRD pattern by TOPAS software which uses Rietveld method of fitting. It is necessary to enter the structures – ferrite, martensite or austenite.

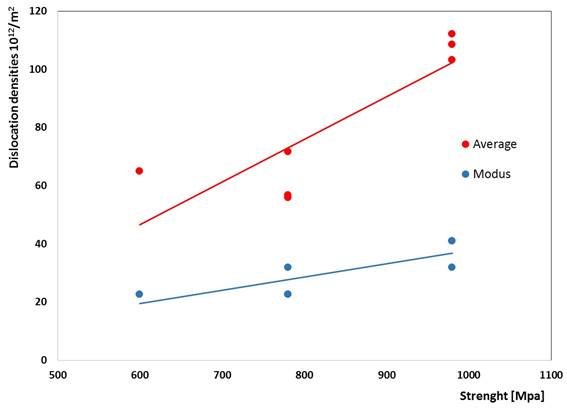

Both parameters KAM and GND include information about microtensions and disorders in the grain which are expression of increased content of low-angle boundaries. Increased amount of misorientation of 0° – 5° is in general mainly observed for grain boundaries and in martensitic grains. By entering the lattice parameter and slip system it is possible to calculate the value of geometric dislocation density using GND [3]. It was found that average value of geometric dislocation density increases with the increased hardness of DP steels, see Fig. 1.

Calculation of several physical properties is possible in the software used for evaluation of the EBSD data, such as OIM or Channel5. Using these programs, it is possible to form the maps or distribution separations of Taylor and Schmidt factors. However, these programs are not able to determine the R – Langford factor which is very suitable for practical metallurgy. This model parameter is still possible to calculate by popLA software from XRD measurements.

[ 1 ] Chaowei Du: Micro-Plasticity Characterization of Martensite, Ferrite, and Dual-Phase Steel, Technische Universiteit Eindhoven, (2016)

[ 2 ] K. Radwanski: Aplication of FEG-SEM and EBSD Methods for the Analzsis of the Restoration Processes Occuring During Continuous Annealing od Dual-Phase Steel Strips, Steel Research, Vol. 86, (2015), p.1379

[ 2 ] L. Schemmann, S. Zaefferer, D. Raabe, F. Friedel, D. Mattissen: Alloying effects on microstructure formation of dual phase steels, Acta Materialia 95 (2015) 386–398

Figure 1. The effect of GND (geometrically necessary dislocations) on the strength of DP steel.