SURFACE STRUCTURE OF CHEMICALLY MODIFIED POLYMERIC NANOFIBERS STUDIED BY MOLECULAR MODELING

Petr Ryšánek, Marek Malý, Pavla Čapková

Faculty of Science, J. E. Purkyně University, České mládeže 8, 400 96 Ústí nad Labem

Polymeric nanofibers – nylon 6 prepared by electrospinning were modified by various antimicrobial agents in order to optimize antimicrobial effect and structure stability of modified nanofibrous textile for application in air filtration. Three different antimicrobial agents have been tested for practical use. chlorhexidine (CHX), 1-dodecyltrimethylammonium bromide (DTAB), benzyltrimethyammonium bromide (BTAB). Modified nanofibers were studied by analytical techniques (XRD, XPS, SEM, Zeta potential measurements) and also by molecular modeling. The aim of molecular modeling studies was to confirm the stability of modification and also to clarify the surface arrangement of modified nanofibers.

Molecular modeling calculations have been carried out in Materials Studio and Amber modeling environment. Our previous XRD study revealed [1] that nylon 6 nanofibers prepared by electrospinning contain both alpha and gamma phase, where alpha phase is in core and gamma phase in surface shell in nylon 6 nanofibers. Therefore for our study we use gamma phase interacting with modifying agents.

The calculations in Materials Studio, COMPASS II forcefield, were made for single molecule of modifying agent. the motivation for this study was calculate interaction energy between modifying agent and the nanofiber surface. From the interaction energy, the stability of modification could be confirmed. The calculated interaction energies for all three modifying agents are in Table 1.

Table 1: Calculated interaction energy PA6 surface/ligand using two different force fields COMPASSII and GAFF2.

|

Sample |

Interaction energy (kcal/mol) COMPASSII |

Interaction energy (kcal/mol) GAFF2 |

|

PA6/DTAB |

-43.13 (3.14) |

-53.06 (6.58) |

|

PA6/BTAB |

-31.40 (4.65) |

-48.35 (3.18) |

|

PA6/CHX |

-57.62 (3.75) |

-70.91 (4.76) |

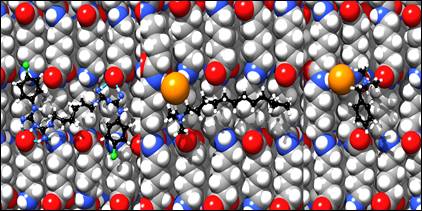

The calculations in Amber 16, GAFF2 force field, were also made for single molecule of ligands to confirm the interaction energies calculated by COMPASS II force field. The values of interaction energies are in Table 1. The comparison of the values shows good agreement between selected force fields calculations. The representative positions of single molecules of aditives are in the Figure 1.

Figure 1: Representative positions of isolated ligands CHX (left), DTAB (middle) and BTAB (right) on the crystalline surface of nylon 6 (gamma phase).

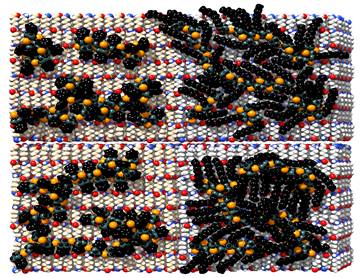

Ambrer software was also used for calculation using realistic concentratuions of DTAB and BTAB. The cvoncentrations of aditives were determined by XPS analysis, which provide information about surface chemistry to the depth about several nanometers [2]. These calculations were made for the clarifying of the surface structure of modified nanofibers. The simulated surfaces are in the Figure 2.

Figure 2: Simulated systems of BTAB (41 molecules) and DTAB (38 molecules) molecules on the crystalline surface of nylon 6 (gamma phase)

Molecular simulations helped us to confirm the stability of modification of nanofibers by antibacterial aditives. Very important result was also the simulation of nanofiber surface with realistic concentration of aditives, which showed, that the concentration used is sufficient to cover almost whole surface of the nanofiber. This is important for future applications.

References:

1. P. Čapková, A. Čajka, Z. Kolská, M. Kormunda, J. Pavlík, M. Munzarová, M. Dopita, D. Rafaja, Journal of Polymer Research 22 (2015), 101.

2. P. Ryšánek, M. Malý, P. Čapková, M. Kormunda, Z. Kolská, M. Gryndler, O. Novák, L. Hocelíková, L. Bystrianský, M. Munzarová, Journal of Polymer Research 22 (2017), 208.

The authors acknowledge the assistance provided by the Research Infrastructure NanoEnviCz, supported by the Ministry of Education, Youth and Sports of the Czech Republic under the project No.: LM2015073. Project of Internal Grant Agency SGS UJEP: Modification of polymeric nanofiber textile project No.: UJEP‑SGS‑2016‑53‑003-3 is also acknowledged.