Structural evolution of Ta-alloyed Ti-Al-N hard coatings

T. Roch, M. Janík, M. Mikula, M. Truchlı, D. Plaienka, M. Pleva, P. Kú

Department of Experimental Physics, Faculty of Mathematics Physics and Informatics, Comenius University in Bratislava, Mlynska Dolina, 842 48 Bratislava, Slovakia

roch@fmph.uniba.sk

Well known Ti-Al-N hard coatings commercially used for abrasive wear protection in machine industry exploit combination of extreme hardness with good oxidation resistance. But inherent brittleness limits their applications. In general, hard coatings have to show high toughness, elasticity and good adhesion to substrate, while keeping hardness and thermal stability at reasonable levels. Enhancement of toughness in terms of ductility increase was predicted for TiAlN (cubic B1) alloyed with transition metal, with best results for Ta, Mo and W [1]. Compelling improvements were predicted by numerical simulations and some experiments by means of low tantalum alloying (y < 0.1) of Ti1-x-yAlxTayN coating material [2,3]. Hardness increased up to 40 GPa and spinodal decomposition process shifted from 900 °C to 1200 °C.

Here, we investigated this material with even higher Ta content y. Our aim was the detailed X-ray diffraction structural analysis of Ti1-x-yAlxTayN (TATN) coatings as-deposited on monocrystalline Si (001), Al2O3 (0001) and on polycrystalline tungsten carbide substrates with y = 0 - 0.6. Deposition was performed using reactive unbalanced DC magnetron co-sputtering from TiAl and Ta tilted targets in a flowing Ar + N2 mixture atmosphere at 0.5 Pa. Samples were mounted on the heated holder at different positions with respect to the targets, yielding different Ta content in TATN thin films. The chemical elemental composition determined by energy dispersive spectroscopy showed monotonic increase of Ta content with the decrease of (sample, Ta-target) distance.

|

(a) |

(b) |

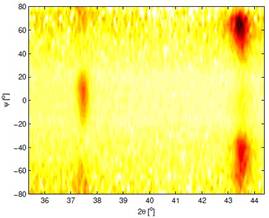

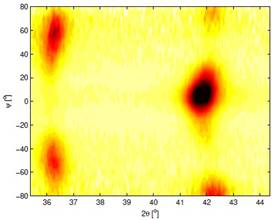

Figure 1. 2q/q-y area map around 111 and 002 reflections of sample with (a) y = 0 and (b) y = 0.46. |

|

The XRD analysis involved microstructure determination, texture specification by pole figures measurement and residual stress analysis using sin2y method. Figures 1a and 1b show measurements of area maps with combined 2q/q -scans at varying y tilt positions of sample without Ta (TiAlN) and sample with higher Ta content (y = 0.46), respectively. These patterns show very clearly presence of various structural effects together. With increasing tantalum content, the phase remains cubic NaCl type, the lattice parameter increases and coherent domain size decreases. Regardless of substrate type in all coatings the texture evolves from 111 (for y = 0) to 001 orientation

with increasing y. Polar figures in 111 reflection show presence of another preferential orientation within plane nearly parallel to the surface. The texture is mainly influenced by the effect of directional sputtering on tilted substrates. Residual stresses evolved from tensile stress of 1.2 GPa in the coatings without tantalum (y = 0) to compressive stress up to −4.4 GPa with increasing Ta content.

The investigation of mechanical properties supported by density functional theory simulations show relatively stable hardness ~30 GPa and monotonic decrease of elastic stiffness with the increase of Ta content. Calculations suggest progressive modification of the metal-N bonding character from ionic (y = 0) to more covalent (y > 0). Analysis of structural and mechanical properties on wide set of samples enabled to indirectly estimate their correlation with growth processes.

1. D. G. Sangiovanni, L. Hultman, V. Chirita, Acta Mater., 59, (2011), 2121.

2. R. Rachbauer, D. Holec, P. H. Mayrhofer, Surf. Coat. Technol., 211, (2012), 98.

3. R. Rachbauer, D. Holec, P. H. Mayrhofer, Appl. Phys. Lett., 97, (2010), 151901.

Authors would like to acknowledge a support by the Research & Development Operational Program funded by ERDF supporting the project implementation: ITMS 26220220004.