STRUCTURE ANALYSIS OF ANTIBACTERIAL FILTRATION MEDIA

P. Ryšánek1, P. Čapková1, L. Hocelíková1, M. Gryndler1, L. Bystrianský1, M. Malý1, M. Munzarová2

1Faculty of Science, J. E. Purkyně University, České mládeže 8, 400 96 Ústí nad Labem

2Nanovia, s. r. o., Litvínov, Podkrušnohorská 271, 436 03 Litvínov – Chudeřín

Polymer nanofibers are used in wide range of activities in everyday life, such as: filtration [1], protective closing, pharmaceuticals [2], etc. Due to very small size of pores, these nanofiber in the form of nanotextile are widely used as nanofilters [3]. These nanofilters can capture bacteria [4] and also some kind of viruses [5].

The most versatile method for nanofiber preparation is electrospinning. The industrial application of electrospinning is Nanospider technology, which can produce nanotextiles in high amounts.

We have studied two representatives of polymers (nylon 6, polyvinylidene fluoride (PVDF)) which are used as nanofilters. By one step synthesis we have prepared antibacterial nanofilters by adding antibacterial agents to the solution for electrospinning. We have chosen chlorhexidine (CHX), 1-dodecyltrimethylammonium bromide (DTAB) and benzyltrimethylammonium bromide (BTAB) for modification of nylon 6, and only DTAB for modification of PVDF. We focused our research on structure determination of pristine nanotextiles and on structural changes after the modification by antibacterial agents. We have also studied surface chemistry of the samples, antibacterial properties and with the help of molecular modeling the interactions between polymer and the antibacterial agent.

Nylon 6

Structure of nylon 6 polymer is very well known. It was resolved that nylon 6 is polymorphic and has two crystal structures: alpha form which was described by Brill [6] and Holmes [7] and gamma form which was determined by Holmes [7]. Both structures are monoclinic and differ from each other by density and arrangement of polymeric chains.

It is known that the electrospinning preparation of nylon 6 nanofibers leads to three structural phases: alpha, gamma and amorphous phase of nylon 6. The dependence of nylon 6 structure on the Nanospider arrangement was investigated. It has been determined, that the phase composition of nylon 6 nanofibers (i.e. the content of alpha, gamma and amorphous phase) depends on electrode distance. In our previous work the core-shell structure model has been suggested, based on combination of XRD and XPS measurements [8]. The fibers exhibit also very strong texture in direction (010).

After the modification by antibacterial agents, there has been significant change of the phase composition of nylon 6 in the case of modification by CHX and BTAB. The representative diffraction diagrams of pristine nylon 6 and nylon 6 modified by CHX are on Figure 1.The results of phase composition are in Table 1. Modification also caused smoother and broader diffraction profiles, which indicated lower crystallinity and smaller crystalline domains in modified samples.

Figure 1 : Diffraction profile for pure PA6 (a) and for modified PA6/CHX (b). Calculated profiles for α phase of PA6 (green) and γ phase of PA6 (red) are shown.

Table. 1: Phase composition of investigated samples.

|

Sample |

a phase [wt. %] |

g phase [wt %] |

|

PA6 |

64 ± 5 |

36 ± 5 |

|

PA6/DTAB |

67 ± 5 |

33 ± 5 |

|

PA6/BTAB |

54 ± 5 |

46 ± 5 |

|

PA6/CHX |

54 ± 5 |

46 ± 5 |

PVDF

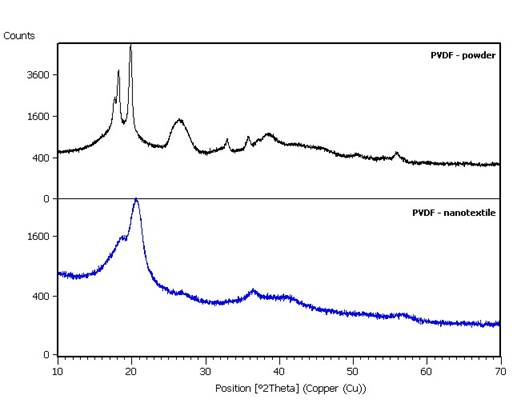

Structure of PVDF has been also studied [9, 10]. PVDF is a semicrystalline polymer with 5 possible conformations [11]. We have studied the changes of structure of the polymer after the electrospinnig process and also after the modification by antibacterial agent. For modification of PVDF we have chosen only DTAB, because it had the best antibacterial properties. Typical diffraction diagrams of polymer powder and nanotextile are on Figure 2. It is evident, that the alpha phase of PVDF is dominant in powder pristine polymer. For nanotextile there are smaller crystalline domains and possible phase transformation from alpha to alpha - beta phase mixture.

Figure 2. XRD diagrams of powder and nanotextile PVDF.

1. H. R. Ant, M. P. Bajgai, Ch. Yi, R. Nirmala, K. T. Nam, W. Baek, H. Y. Kim, Colloids and Surfaces A: Physicochemical and Enginering Aspects. 370 (2010) 87-94.

2. P. Raghavan, X. Zhao, J. K. Kim, J. Manuel, G. S. Chauhan, J. H. Ahn, C. Nan, Electrochimica Acta 54 (2008), 228-234.

3. O. Labban, C. Liu, T. H. Chong, V. J. H. Lienhard, Journal of Membrane Science. 521 (2017), 18–32

4. M. T. Amin, A. A. Alazba, and U. Manzoor, Advances in Materials Science and Engineering vol. 2014, article ID 825910.

5. T. Burnouf, M. Radosevich, H. A. Goubran, H. Willkommen, Current Nanoscience, 1 (3) (2005), 189-201

6. R. Brill, Zeitschrift für Physikalische Chemie B 53 (1943), 61-66.

7. R. Holmes, C. W. Burn, D. L. Smith, Journal of Polymer Science 17 (1955), 619-624.

8. P. Čapková, A. Čajka, Z. Kolská, M. Kormunda, J. Pavlík, M. Munzarová, M. Dopita, D. Rafaja, Journal of Polymer Research 22 (2015), 101.

9. A.J. Lovinger, Poly(vinylidene fluoride), in: D.C. Bassett (Ed.), Developments in Crystalline Polymers, Applied Science Publishers, London, 1982 (Chapter 5).

10. F.J. Lu, S.L. Hsu, Polymer 25 (1984) 1247.

11. A.J. Lovinger, Macromolecules 15 (1982) 40.

The authors acknowledge the assistance provided by the Research Infrastructure NanoEnviCz, supported by the Ministry of Education, Youth and Sports of the Czech Republic under Project No. LM2015073.

The authors also acknowledge the support by the student project UJEP-SGS-163-07‑02 “Modification of polymeric nanofiber textiles for antibacterial filtration and biomedical applications“.