Textural and microstructural analysis by EBSD method in the USSK conditions

M. Černík, P. Vranec, L. Hrabčákova

1U.S.Steel Košice, s.r.o., Vstupný areál U.S. Steel, 044 54 Košice

mcernik@sk.uss.com, pvranec@sk.uss.com, lhrabcakova@sk.uss.com

The analysis of rolled steel plates is significant part of the metallographic analyses. Since the 1971 up to 2006 the textures have been analyzed only by methods of x-ray diffraction (XRD) using XRD device with texture goniometer. Important knowledge extension about the textures occurred with application of the diffraction methods of back-scattered electrons EBSD. This method offers possibility to analyze the sample not only from the texture point of view, but also from the microstructure point of view (grain size, high and low angle grain boundaries, grain misorientation, twins).

Database, which includes cold and hot rolled sheets, continual and batch annealed samples, double reduced samples, was created by analyzing many samples (ca. 2000) of steel plates. From the material point of view these are mainly samples of tinplates, dynamo sheets, automotive sheets, deep-drawn, IF plates. Except of these materials also plates from austenitic steels, plates with residual austenite in TRIP steels were also analyzed.

New microscope with EBSD camera with the speed of nearly 1000 frames per second for the perfectly prepared sample was purchased last year. The older camera reached only 40 frames per second at the same quality of the measurement. The advantage of the new system is also a possibility of continual sample scanning (large area mapping). Thanks to this property it is possible to measure samples with big grains, ca. 300 microns. Samples with such structure are unable to be measured via classic XRD device, as there is insufficient amount of grains for orientation distribution function (ODF) calculations on the measured area. These samples are only possible to be measured by neutron radiation, as the sample volume and penetration of neutron radiation is dimensionally in cm.

Powerful software for the processing of the measured EBSD data allows processing of large files of measured data ca. 5 millions, the ODF calculation, texture fibers, inverse pole figure map, grain size distribution, misorientation, grain boundaries, twins etc. The main problem of this method is sample preparation. For common ferritic steels the standard metallographic procedure is enough – grinding, polishing on diamond paste and final polishing in vibration polisher in colloid solution with nano particles of ca. 40 – 50 nm size. Such procedure is however insufficient for samples containing austenite. At our department the procedure with finishing by electrolytical polishing was approved as sufficient. The best results were obtained for cooling the electrolyte to ca. 0 – 10°C, voltage of ca. 10 V in the perchloric acid and ethanol in the 1:10 ratio.

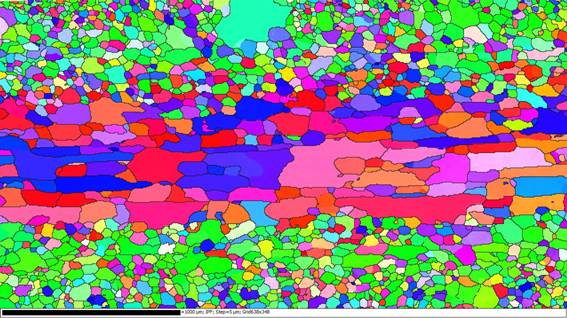

An example of dynamo sheet with coarse-grained structure, which was measured by sequential scanning of the pictures through the whole sample area, is given in Fig. 1. The dimensions of the sample are approximately 25 mm of length and 2 mm of thickness. The results are comparable to the results measured using the neutron radiation.

Figure 1. IPF map of hot rolled non-oriented steel sheet.