Measuring of residual stresses in strongly textured thin films

E. Dobročka1, P. Novák2, D. Búc3

1Institute of Electrical Engineering, Slovak Academy of Sciences, Dúbravská cesta 9,841 04 Bratislava, Slovak Republic

2Institute of Nuclear and Physical Engineering, Faculty of Electrical Engineering and Information Technology, Slovak University of Technology, Ilkovičova 3, 812 19 Bratislava, Slovak Republic

3Institute of Electronics and Photonics, Faculty of Electrical Engineering and Information Technology, Slovak University of Technology, Ilkovičova 3, 812 19 Bratislava, Slovak Republic

edmund.dobrocka@savba.sk

The presence of

residual stresses in the near surface region of bulk materials and in thin

films is a general problem of various technologies. Among a number of methods

developed for stress analysis, X-ray diffraction methods are of special

importance due to their capability to analyze the depth variation of the

residual stresses. Since the first stress determination by X-ray diffraction in

the 1930s a large variety of measuring methods and evaluation procedures were

developed. While the standard ![]() method can be easily used for bulk materials, it is not applicable

for thin films, where steep stress gradient perpendicular to the sample surface

can be present. In this case the methods based on grazing incidence (GI) set-up

are more appropriate. The constant (and usually small) angle of incidence α,

that is a characteristic feature of GI X-ray diffraction, ensures that the

information depth does not change during the measurement. The GI method of

stress determination is classified as multiple {hkl} mode in comparison

with the

method can be easily used for bulk materials, it is not applicable

for thin films, where steep stress gradient perpendicular to the sample surface

can be present. In this case the methods based on grazing incidence (GI) set-up

are more appropriate. The constant (and usually small) angle of incidence α,

that is a characteristic feature of GI X-ray diffraction, ensures that the

information depth does not change during the measurement. The GI method of

stress determination is classified as multiple {hkl} mode in comparison

with the ![]() method, that uses only one set of {hkl} planes while the

angle of sample inclination χ varies. The GI method is based on the fact

that all diffraction vectors contributing to the GI diffraction pattern make

different angles with the surface normal of the sample and provide sufficient

set of data for stress evaluation. However, this method of stress measurement

fails if the analyzed layer is strongly textured. In this case the orientation

of the diffraction vectors is sharply localized and the number of diffractions

registered in the measurement performed at constant α and χ

(usually

method, that uses only one set of {hkl} planes while the

angle of sample inclination χ varies. The GI method is based on the fact

that all diffraction vectors contributing to the GI diffraction pattern make

different angles with the surface normal of the sample and provide sufficient

set of data for stress evaluation. However, this method of stress measurement

fails if the analyzed layer is strongly textured. In this case the orientation

of the diffraction vectors is sharply localized and the number of diffractions

registered in the measurement performed at constant α and χ

(usually ![]() ) may be insufficient for the evaluation of the stress state.

) may be insufficient for the evaluation of the stress state.

In the presented

contribution a modified method combining multiple {hkl} and multiple χ

modes of stress measurements is outlined. Measuring at ![]() can significantly increase the number of accessible diffractions. The

analyzed film is supposed to have a fibre texture with the texture axis

can significantly increase the number of accessible diffractions. The

analyzed film is supposed to have a fibre texture with the texture axis ![]() parallel to the surface normal. The most probable values of angles ψ

between the diffraction vectors and the direction

parallel to the surface normal. The most probable values of angles ψ

between the diffraction vectors and the direction ![]() are calculated from single crystal data. In order to measure the

diffraction with Bragg angle θ at selected angle of incidence α, the tilting angle χ and the rotation angle ω of the

goniometer have to be calculated according to relations

are calculated from single crystal data. In order to measure the

diffraction with Bragg angle θ at selected angle of incidence α, the tilting angle χ and the rotation angle ω of the

goniometer have to be calculated according to relations

![]()

and

![]()

Due to rotational symmetry of the texture there is no specific restriction for the azimuthal angle ϕ.

The described

method was used for evaluation of biaxial stress in ZnO layers deposited on

(111) GaP substrates. The stress measurements were performed on as deposited

samples and repeated after annealing at 300 °C for 1 hour in N2

atmosphere. The details of sample preparation are given elsewhere [1]. The

layers exhibit strong fibre texture with [001] axis perpendicular to sample

surface, the 002 pole figure is shown in Fig. 1. Due to this texture, only

three diffractions (002, 103 and 203) with sufficient intensities can be used

for stress evaluation, when the diffraction pattern is recorded in standard GI

set-up with ![]() and

and ![]() . However, polycrystalline

hexagonal ZnO provides 20 diffractions in the range

. However, polycrystalline

hexagonal ZnO provides 20 diffractions in the range ![]() (for Cu Kα radiation) with relative intensities above 1%, 17

of them are accessible by an appropriate choice of angles χ and ω

for a constant angle of incidence

(for Cu Kα radiation) with relative intensities above 1%, 17

of them are accessible by an appropriate choice of angles χ and ω

for a constant angle of incidence ![]() . Ten strongest diffractions were measured for different values of ψ

around the ideal angle corresponding to single crystal data.

. Ten strongest diffractions were measured for different values of ψ

around the ideal angle corresponding to single crystal data.

|

|

|

Figure 1. 3D Pole figure 002 of ZnO layer measured within the angular range χ = 0° - 30°. |

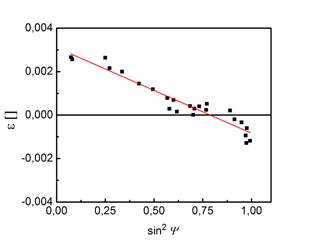

Figure 2. sin2ψ plot based on the combination of multiple hkl and multiple χ mode of stress measurement. |

The results for

annealed sample are collected in standard ![]() plot in Fig. 2. It

is seen that the points cover almost uniformly the whole range of the parameter

plot in Fig. 2. It

is seen that the points cover almost uniformly the whole range of the parameter

![]() . The crystallite group method proposed for thin films with fibre

texture [2] was employed for the calculation of biaxial stress. The appropriate

relation for hexagonal crystals with this type of texture has the form

. The crystallite group method proposed for thin films with fibre

texture [2] was employed for the calculation of biaxial stress. The appropriate

relation for hexagonal crystals with this type of texture has the form

![]()

It was found that the stress in ZnO layers is compressive and its value decreased significantly upon annealing from 3 GPa to 0.5 GPa.

The method

enables to analyze also the depth variation of the stress by changing the angle

of incidence α. However, approaching the critical angle for total

external reflection, an appropriate correction of measured diffraction angles

has to be made. In addition, for inclined geometry (![]() ) the plane of refraction does not coincide with the diffraction

plane and the standard corrections have to be modified [3]. Further

improvements can be achieved by applying more sophisticated models developed

for thin films [4].

) the plane of refraction does not coincide with the diffraction

plane and the standard corrections have to be modified [3]. Further

improvements can be achieved by applying more sophisticated models developed

for thin films [4].