Study of ω particle growth in titanium alloys using x‑ray diffraction

Jana Šmilauerová, Václav Holý, Zdeněk Matěj, Jiří Pospíšil

Faculty of Mathematics and Physics, Charles University in Prague, Ke Karlovu 5, Praha 2, 121 16, Czech Republic

jana.smilauerova@gmail.com

Metastable β titanium alloys exhibit unique mechanical and functional properties, such as high specific strength, excellent corrosion resistance and good biocompatibility [1]. Therefore, metastable β titanium alloys are prospective materials for a number of application fields, including automobile and aircraft industry or biomedical devices. Metastable β titanium alloys contain a sufficient amount of β-stabilizing elements to retain the high temperature β phase (body-centred cubic) in a metastable state upon rapid cooling to room temperature. However, the thermodynamically stable composition consists of a mixture of the β phase and particles of the low temperature α phase (hexagonal close-packed) [2]. Phase transformations occurring in these alloys are very complex, as several additional metastable phases can form. One of the most intriguing of these phases is the ω phase which occurs as nanoparticles of hexagonal structure homogeneously distributed throughout the β matrix. These particles display an ellipsoidal morphology and are coherent with the β matrix. The ω particles form by a diffusionless displacive transformation from the parent β phase [3] and upon ageing at elevated temperatures further evolve by a diffusion-driven process [4]. The exact mechanisms of ω particle formation and growth are still neither satisfactorily described, nor fully understood.

This research was conducted on TIMETAL LCB

(Ti-6.8Mo-4.5Fe-1.5Al in wt.%) metastable β titanium alloy. For the purpose of

this study, single-crystals of this alloy were grown in an optical floating

zone furnace [5]. The resulting

single-crystals were solution treated above the β-transus temperature and

quenched to water. Subsequently, different conditions were prepared from this

material by ageing at 300 °C for 8 h, 16 h, 32 h, 64 h,

128 h and 256 h. Then we measured coplanar reciprocal space maps

around the ![]() ω maximum of

the ω phase and around the {112}β

maximum of the β matrix in all the samples, see Fig. 1 and Fig. 2,

respectively. The ω maxima exhibited an ellipsoidal shape which was fitted

using a model of diffusely scattered intensity. The

shape of {112}β peaks substantially differ

from the ω maxima, as it is affected by diffuse scattering from ω particles and

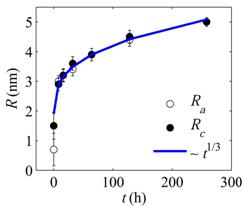

other defects in the structure. From the fit of the shape of ω peaks, the mean

ω particle sizes along its c-axis (denoted by Rc) as

well as along its a-axis (Ra) were calculated, see

Fig. 3. It was found out that the size of the aged ω particles is almost

spherical and that the radius obeys a

ω maximum of

the ω phase and around the {112}β

maximum of the β matrix in all the samples, see Fig. 1 and Fig. 2,

respectively. The ω maxima exhibited an ellipsoidal shape which was fitted

using a model of diffusely scattered intensity. The

shape of {112}β peaks substantially differ

from the ω maxima, as it is affected by diffuse scattering from ω particles and

other defects in the structure. From the fit of the shape of ω peaks, the mean

ω particle sizes along its c-axis (denoted by Rc) as

well as along its a-axis (Ra) were calculated, see

Fig. 3. It was found out that the size of the aged ω particles is almost

spherical and that the radius obeys a ![]() dependence, where t is the ageing

time. This dependence was observed also for a number of other systems and is

known as the Lifshitz, Slyozov and Wagner model [6]. This law holds for diffusion-controlled growth of particles under

the influence of precipitate-matrix interface energy. The components of the

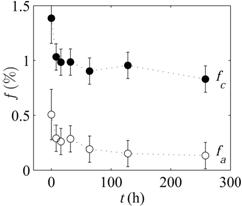

misfit of the ω lattice with respect to the lattice of the β matrix were also

determined, see Fig. 4. The largest misfit is observed in the solution

treated sample. With increasing ageing time, the misfit is decreasing. This

effect is most likely caused by an outward diffusion of alloying elements from

the volume of the ω particles which accompanies the growth of the ω phase

particles.

dependence, where t is the ageing

time. This dependence was observed also for a number of other systems and is

known as the Lifshitz, Slyozov and Wagner model [6]. This law holds for diffusion-controlled growth of particles under

the influence of precipitate-matrix interface energy. The components of the

misfit of the ω lattice with respect to the lattice of the β matrix were also

determined, see Fig. 4. The largest misfit is observed in the solution

treated sample. With increasing ageing time, the misfit is decreasing. This

effect is most likely caused by an outward diffusion of alloying elements from

the volume of the ω particles which accompanies the growth of the ω phase

particles.

|

|

|

Figure 1. Coplanar

reciprocal space maps measured in the

|

Figure 2. Coplanar reciprocal space maps measured in the {112}β maximum of the β matrix. Solution treated sample (a) and samples after ageing for 8 – 256 h (b ‑ g). |

|

|

|

Figure 3. The dependence of the ω particle radii on the ageing time. |

Figure 4. The dependence of the misfit components along the two main axes of the hexagonal ω lattice on the ageing time. |