MStruct extension for line profile analysis of individual diffraction peaks – application to materials with anisotropic line broadening

Z. Matěj1, T. Brunátová1, L. Matějová2,3, V. Valeš1,4,

D. Popelková5, R. Kužel1

1Faculty

of Mathematics and Physics, Charles University in Prague,

Ke Karlovu 5, 121 16 Praha 2, Czech Republic

2VŠB-Technical University of Ostrava, 17. listopadu 15, Ostrava – Poruba

3Institute of Chemical Process Fundamentals of the ASCR, v.v.i., Rozvojova 2, Praha 6

4J. Heyrovsky Institute of Physical Chemistry of the ASCR, v.v.i., Dolejškova 3, Praha 8

5Institute of Macromolecular Chemistry of the ASCR, v. v. i., Heyrovského nám. 2, Praha 6

Keywords: XRD, anisotropy, strain, nanorods

Abstract

Application of an extension of the MSTRUCT powder diffraction software for refinement of individual diffraction line profile parameters is illustrated on the case studies of nanocrystalline anatase TiO2 particles, Na2Ti6O13 titanate nanorods and CeTi2O6 titanate samples with strong anisotropic size and strain diffraction line broadening.

Introduction

The Rietveld and whole powder pattern modelling (WPPM) methods [1] are the most common approaches used for powder diffraction analysis nowadays. They can profit from general as well as material specific structural models and overcome the peak overlap problem. This is especially true for low symmetry and multiphase materials. Due to complexity of these methods it can be difficult to understand how particular model parameters are related to experimental data. This is less difficult within the methods of analysis of individual lines, such as the Williamson-Hall plot method or without restrictions to line profile analysis (LPA) also e.g. the sin2(y) method. They offer direct relation between relevant effects in experimental data and model parameters. Unfortunately peak overlap or other difficulties can limit their applicability.

An extension of the Rietveld/WPPM like MSTRUCT software [2] for refinement of profile parameters of individual diffraction peaks is presented. With this extension it is possible to switch off particular physical effects for individual hkl diffraction lines. On the contrary additional pseudo-Voigt profiles can be included in the convolution kernel for these reflections. In this way additional peak shifts or broadening effects can be introduced for specific (strong or not overlapped) diffraction lines whereas the rest of the pattern can be described by a more general “average” (micro)structural model. This is especially useful for fitting diffraction patterns with many peaks from low symmetry and multiphase materials. The refined hkl parameters (shifts, line widths etc.) can later be analysed by other methods. Similar features are available also in TOPAS [3] or Pm2K [4] software.

Crystal properties are anisotropic in nature. This is reflected in dependence of diffraction line parameters on hkl indexes and sample orientation. This anisotropy can be a principal footprint which reveals the presence and nature of important (micro)structure aspects of the studied material, e.g. the presence of specific defects (dislocations, planar faults), crystallites shape anisotropy or a presence of residual stresses.

The Williamson-Hall plot method with LPA parameters refined using the MSTRUCT extension was applied to (1) anatase TiO2 nanoparticles and (2) Na2Ti6O13 and (3) CeTi2O6 titanates.

MSTRUCT extension for refinement of idividual hkl profile parameters

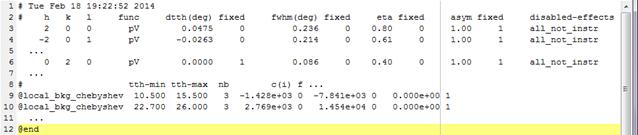

In MSTRUCT there was a possibility to include additional position and broadening correction for individual hkl lines already earlier (before 2013) within the “HKLpVoigtA” effect. Recently the effect was extended with options to save the profile parameters into a separate file (Fig. 1) and switch off specific effects for arbitrary hkl. Usually a general model is used to fit the most of the powder pattern. For few selected hkl reflections of the crystalline phase under study these general models are switched off, with an exception of the instrumental broadening, and an additional phenomenological pseudo-Voigt profile can be included (Fig. 1). The refined profile parameters can be later visualized and analysed by other software.

|

natio.imp

Phkl_HKLeNa2Ti6O13.dat

|

|

Figure 1. Definition of the MSTRUCT “HKLpVoigtA” effect for fitting of individual hkl lines. It contains line profile parameters settings (dtth-shift, fwhm, eta, asym) and definition of local backgrounds (in the bottom). |

Application to anatase nanoparticles

The method was applied to nanocrystalline TiO2 samples prepared by hydrolysis of titanium alkoxides and subsequent calcination [5,6]. The dominant crystalline phase – anatase – can form bipyramidal crystals truncated by (001) lattice planes [6,7]. This would induce strong anisotropic line broadening [6], which is however not observed for the studied samples. It was shown for a certain ratio of (101) and (001) facets the broadening is close to isotropic and simple model of spherical crystallites can be used [6,7].

|

|

|

|

Figure 2. Parts of the measured diffraction pattern of

a sodium-titanate nanotubes sample heated at 850°C for 105 min in air. |

Figure 3. Integral line widths (bhkl) of selected Na2Ti6O13

diffraction lines plotted vs. the Scherrer constant (Khkl) for the model of rod-like crystallites with oval

basis [8]. |

Na2Ti6O13 titanate nanorods

The full potential of the MSTRUCT extension was utilized in the analysis of powder patterns from sodium-titanate nanorods formed by thermal heating of titanate nanotubes [8] (above 850°C). Beside the main titanate phase with about 100 reflections there are strong peaks from anatase and rutile phases in the experimental patterns. This complicates extraction of line profile parameters. Nevertheless it is evident in the measured patterns that broadening effects are strongly anisotropic (Fig. 2, 3) and the effect is related to nature of this material to form nanorods with axis parallel to the crystal monoclinic axis [8].

|

|

|

Figure 4. Williamson-Hall plot for selected CeTi2O6

diffraction lines. Shadow circles mark reliable hkl widths which were used for an initial guess (black line) of

parameters of the Popa anisotropic strain broadening model. Blue dashed line

shows a dependence of model predicted widths for other analysed reflections. |

Anisotropic strain broadending in CeTi2O6 titanates

Contrary to two previous cases in CeTi2O6 titanate samples prepared by heating of sol-gel Ti-Ce mixed oxides at temperatures above 750°C the anisotropic strain broadening was the dominant effect [9] (Fig. 4). It was possible to describe this effect by the phenomenological model developed by Popa [10]. According to this model the microstrain (ehkl) is described by 9 model parameters (E1, … E9) [10]

|

|

(1) |

where Hhkl = 1/dhkl is the diffraction vector length, “a“ is the lattice parameter and ehh is an additional microstrain scaling parameter.

Summary

The presented MSTRUCT extension can be utilized for refinement of individual hkl lines profile parameters in whole diffraction patterns from low symmetry or multiphase materials with many overlapped reflections. Specific size broadening models accounting for natural crystal shapes were used to describe size broadening in case of anatase nanoparticles and sodium-titanate nanorods. Anisotropic microstrain in CeTi2O6 titanate samples was described by the phenomenological model of Popa. The case studies here illustrate that analysis of individual diffraction lines and the whole pattern modeling approach are complementary methods. The former one offers a qualitative description, ideas and initial parameters for the starting model. The later method gives qualitative results.

References

1. P. Scardi, M. Leoni, Acta Cryst. A, 58, (2002), 190.

2. Z. Matěj, R. Kužel, MSTRUCT, www.xray.cz/mstruct (May 20, 2014)

3. Coelho software, TOPAS Academic, www.topas-academic.net (May 20, 2014)

4. M. Leoni, T. Confente, P. Scardi, Z. Kristallogr. Suppl., 23, (2006), 249.

5. L. Matějová, Z. Matěj, O.

Šolcová, Micro. Mesoporo. Materials, 154, (2012), 187.

6. Z. Matěj,

L. Matějová, R. Kužel, Pow. Diffr.,

28, (2013), S161.

7. Z.

Matěj, R. Kužel, Materials Struct. Chem. Biol. Phys. Tech., 19(2), (2012), 121, www.xray.cz/mstruct.

8. T. Brunatová, Z. Matěj, P. Oleynikov, S. Daniš, D. Popelková, X. Zou, R. Kužel, submitted to Mater. Character. (Feb 2014).

9. V. Valeš,

L. Matějová, Z. Matěj, T. Brunátová, V. Holý, J. Phys. Chem. Sol., 75, (2014), 265.

10. N. C. Popa, J. Appl. Cryst., 31,

(1998), 176.

Acknowledgements.

This work has been supported by the Grant Agency of the Czech Republic (project no. 14-23274S) and within the Charles University Research Center “Physics of Condensed Matter and Functional Materials” (no. UNCE 204023/2012).

,

,