auxiliary programs for

diffraction experiments

Jiří Čapek1,

a, Zdenek Pala1, 2

1Department of Solid State

Engineering, Faculty of Nuclear Sciences and Physical Engineering, Czech

Technical University in Prague

2Institute of Plasma Physics, Academy

of Sciences of the Czech Republic

acapekjir@fjfi.cvut.cz

Because of recurring pleas of

colleagues who are frequent users of X-ray diffraction results and who wanted

to know the relevant volume of material which was irradiated, programs for

calculation of penetration depth and linear absorption coefficients of

crystalline phases were written in MatLab environment. In addition to it, we

were often faced with oddly positioned Debye rings obtained in back reflection

experiment. Debye rings’ convenient location on area, 2D, detector was, thus,

achieved by repeatedly performing the experiments. That had led us to create a

program which would visualize the outcome for selected experimental parameters.

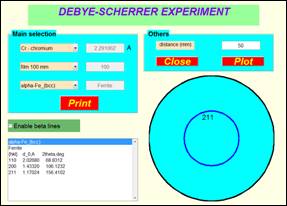

Debye software was created as a visual aid for users

doing the so called the back reflection experiment (or backscattering

Debye-Scherrer experiment) [1]. It is a basic method for qualitative

determination of real structure of materials. In materials only planes, which

are oriented in the manner satisfying the Braggs’ law, can diffract. The

diffracted radiation has a character of diffraction cones with the apex angle

of 4θ. If this diffracted radiation impacts on a 2D detector, the so

called Debye rings are detected. The user can make a model of the experiment

upon changing the experimental parameters and also can check an expected result

for untextured polycrystalline fine-grained materials. This is especially

helpful for setting the right distance between the irradiated sample and 2D detector

when the dimension of the detector is known. In Fig. 1, there is the result for

standard alpha-ferrite steel in the distance of 50 mm from the detector when

radiation from X-ray tube with chromium anode is used.

|

|

|

|

Figure 1. User interface of the debye software. |

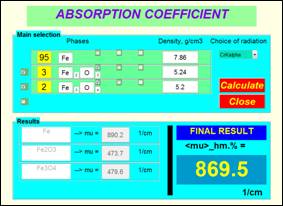

Figure 2. User interface of the absorption coefficient software. |

Absorption coefficient software was created because

it is de rigueur to know the values of linear absorption/attenuation

coefficients when the penetration depth is to be calculated since it describes

the reduction of an energy beam upon passing through a specific material [2].

For calculation of a linear absorption coefficient it is necessary to know the

amount of each phase in material, densities and chemical formulas of the

phases. In Fig. 2, there is the user interface of the program with the result

of alpha-ferrite steel with oxidation layer (again for CrKα radiation). This constant is subsequently applied in the

calculation of corresponding penetration depth as seen in Fig. 3.

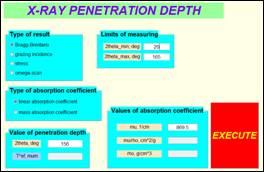

X-ray penetration depth software was created because

the users of XRD results must be informed about the volume of the material to

which the results are relevant. Irradiated volume is given by irradiated

surface, defined by experimental set-up and the inserted slits, multiplied by

penetration depth. Most commonly, the penetration depth is represented by

values of the so called effective

penetration depth Tef which defines the thickness of surface

layer that gives rise to 63 % of diffracted intensity [1]. Hence, this software provides the opportunity to

furnish users with Tef values,

or courses, for the given radiation penetrating the irradiated material. Final

values generally depend on an incidence, a rebound angle and on an absorption

coefficient. The user can choose between four types of experimental set-up.

Except for standard Bragg-Brentano geometry and grazing incidence diffraction,

courses of Tef during

residual-stress-aimed diffraction experiment for ω diffractometer can be

visualized for all measured tilts and Tef

for ω-scans can be plotted as well [3]. User interface of this program

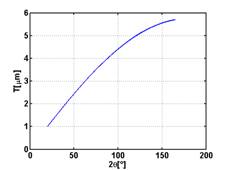

is in Fig. 3 on the left while on the right; there is the result of Tef course for linear

absorption coefficient calculated above and Bragg-Brentano geometry.

|

|

|

|

Figure 3. User interface of the X-ray penetration depth software. |

|

The programs are available for users who have at their disposal MatLab

from http://electron.fjfi.cvut.cz/drupal/software-laborator-strukturni-rentgenografie.

1.

I.

Kraus, N. Ganev, Difrakční analýza mechanických

napětí. Praha: ČVUT, 1995. ISBN 80-01-01366-9.

2.

B.

D. Cullity, S. R. Stock, Elements of

X-ray Diffraction. New Jersey: Prentice Hall, 2001. ISBN 0-201-61091-4.

3.

M.

Birkholz, Thin Film Analysis by X-ray

Scattering. Weinheim: WILEY-VCH, 2006. ISBN 978-3-527-31052-4.

This work was supported by the Grant Agency of the

Czech Technical University in Prague, grant No. SGS13/219/OHK4/3T/14.