Fe2O3/TiO2

nanoparticles – a complex structural study

V. Valeš1,

M. Buljan2, S. Bernstorff3, S. Mangold4, V. Holý1

1Faculty of Mathematics and Physics,

Charles University, Ke Karlovu

5, 121 16 Praha, Czech Republic

2Ruder Bošković

Institute, Bijenička cesta

54, 10000 Zagreb, Croatia

3 Elettra –

Sinctrotrone Trieste S. C. p. A., Strada

Statale 14, 34149 Basovizza,

Italy

4 ANKA Synchrotron Radiation Facility,

KIT, Hermann-von-Helmholtz-Platz 1, D-76344 Eggenstein-Leopoldshafen, Germany

vales@mag.mff.cuni.cz

Titania (TiO2)-based

systems have been very intensively studied in last decades because of their

photocatalytic activity, which found broad commercial applications [1]. Functionalized titania

composites, especially Fe2O3/TiO2 systems

attracted a lot of attention recently, since they make it possible to improve

the photocatalytic performance of titania [2]. The ε-phase of Fe2O3 exhibits a very large

magnetic coercivity at room temperature so that Fe2O3/TiO2

in solutions can easily be manipulated by external magnetic field. Fe2O3/TiO2

compact thin layer composites as a photocatalyst can respond to visible light

due to the narrow band-gap of Fe2O3. The optical and

electronic parameters of Fe2O3/TiO2

nanoparticles substantially depend on the width of their size distribution.

In our previous work [3] we dealt with semiconductor

nanoparticles in amorphous silica matrix and we demonstrated that a self-ordering

mechanism of the nanoparticles occurs during the deposition of multilayers. A

spontaneous ordering of nanoparticles resulted in narrowing of the particle

size distribution. In this work we use this approach for the improvement of the

structure of Fe2O3/TiO2 nanoparticle systems,

namely we study the growth of (Fe2O3+TiO2)/SiO2

multilayers and the crystallization of the mentioned nanoparticles during

post-growth annealing. We investigated the ordering and the size distribution of the particles using grazing-incidence small-angle

x-ray scattering (GISAXS) and the inner crystalline structure by x-ray

diffraction (XRD) and x-ray absorption spectroscopy (EXAFS).

The studied (Fe2O3

+ SiO2)/(TiO2 + SiO2)/SiO2 samples

were grown by a sequential deposition, in which 10-period multilayers (with a

layers thickness 0.6, 1 or 2 nm and the SiO2 spacer thickness of 10

nm) were deposited by electron beam evaporation onto rotating Si substrates at

room temperature. The deposition rates were 10 Å/s for SiO2

and 1 Å/s for both Fe2O3 and TiO2. The

samples have been subsequently annealed for 1 h at various temperatures in

vacuum, air or forming gas (FG – Ar + 4% H2). The partial results

have already been published [4].

The powder xrd curves have

been measured by a laboratory diffractometer with a standard x-ray tube (CuKα, 1.4 kW). We used a parallel-beam setup with a

parabolic multilayer mirror in the primary beam and a parallel-plate collimator

and a flat graphite monochromator (to reduce the fluorescence signal from Fe

atoms) in the diffracted beam. The angle of incidence of the primary beam was

kept constant at 0.5 deg to suppress the substrate signal. Small angle grazing

incidence x-ray scattering has been carried out at ELETTRA synchrotron at the SAXS

beamline with the photon energy of 8 keV. The

incidence angle was a few tenths deg above the critical angle of total external

reflection. The scattered radiation was recorded by MAR image plate (2000 ×

2000 pixels). The necessary angular resolution was achieved by a large

sample-detector distance of about 1.9 m; the air scattering was suppressed by

an evacuated flight-tube. The x-ray absorption spectroscopy has been performed

at XAS beamline at ANKA synchrotron. We measured the spectra in the range 150

eV below and 650 eV above the absorption edge of both Fe and Ti in the

fluorescence mode. The measured data have been processed and analyzed by the

standard software package of the programs Athena

and Artemis.

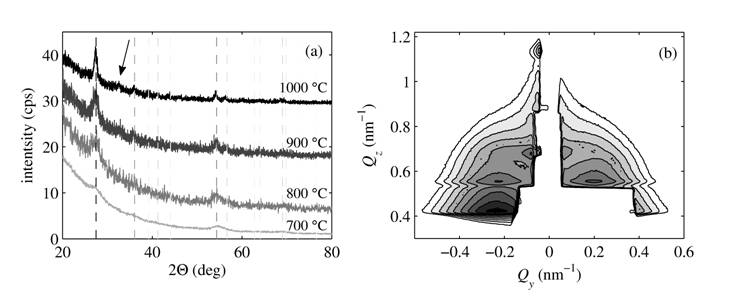

The xrd data show clearly

visible peaks corresponding to the rutile-TiO2. An example of the

evolution of the crystallinity with annealing temperature of the samples with

the layer thickness of 2 nm annealed in the air is displayed in the Fig. 1(a).

The crystallite size obtained by the Sherrer equation

applied to the 110 rutile peak exhibits a systematic growth with annealing

temperature ranging from 4 nm at 700 °C to 13 nm at 1000 °C. For the sample

annealed at the highest temperature, additional peak, which may correspond to

hematite-Fe2O3, arises.

The findings from the xrd data

have been validated by the EXAFS measurements. The absorption spectra around Ti

edge revealed the presence of rutile-TiO2 as expected. From the

measurements around Fe edge we supposed to get information on the local

structure around Fe atoms that we did not obtain form the xrd.

The data were simulated with a model assuming that the sample consists of two

components. The first component is one shell of octahedrally

coordinated oxygen atoms around an iron atom and the second one is two-shell

hematite structure. We observed a systematic increase of the two-shell

component at the expense of simple octahedrons.

The measured GISAXS maps have

been compared to the simulations carried out by our software using a model of

disordered particles in a hexagonal two-dimensional array including interface

roughness. Individual layers are expected to be laterally fully disordered due

to the fact that the particles grow during annealing after multilayer growth.

An example of nicely ordered particles (expressed by well-defined lateral

maxima in the GISAXS map) is displayed in the Figure 1(b). The results from the

GISAXS maps simulations show that with increasing annealing temperature

particle size increases as well as the degree of ordering. At the temperature

of 1000 ºC the particle arrangement as well as inter-layer structure is

broken, probably due to coalescence of particles from different layers. The

particle sizes obtained from GISAXS are in the agreement with those obtained

from xrd.

|

|

|

Figure 1. The evolution of diffraction profiles of samples annealed in the air (a) with diffraction peaks corresponding to rutile (the dashed lines, the grey scale corresponds to the relative peak intensity). The arrow denotes an additional peak corresponding to hematite-Fe2O3. In the panel (b) the GISAXS map in the logarithmic scale with the contour step of 100.15 from sample annealed in the air at 900 ºC is displayed. |

From the analysis of all the data from all

experiments we found out that titanium oxide tends to form ordered rutile

particles from the annealing temperature of 700 ºC with increasing

crystallinity and better ordering for higher temperatures. The particles are

smaller and closer together for thinner samples and vice versa. The multilayer

structure is preserved up to temperatures around 900 ºC. On the other

hand, iron atoms form only very small particles that are not recognizable by

xrd and most of the atoms is surrounded only by octehdrally coordinated oxygen atoms. The best arrangement

of (rutile) particles has been achieved for the sample annealed at 900 ºC

in the air.

1. M.

Hoffmann, S. Martin, W. Choi, D. Bahnemann, Chemical Reviews, 95,

(1995), 69.

2. H.

Cui, W. Ren, W. Wang, Journal of Sol-Gel Science and Technology, 58,

(2011), 476.

3. M.

Buljan, U. Desnica, M. Ivanda, N. Radić, P. Dubček, G. Dražić, K. Salamon, S.

Bernstorff, V. Holý, Physical Review B, 79, (2009), 035310.

4. V.

Valeš, V. Holý, M. Buljan, V. Janicki, S. Bernstorff, Thin Solid Films, 520,

(2012), 4800.