Small-Angle Neutron Scattering contribution to development of some novel materials

P. Strunz1, D. Mukherji2, M. Petrenec3[*], R. Gilles4, G. Schumacher5, G. Pigozzi6, U. Keiderling5, T. Geue7, U. Gasser7, J. Šaroun1 and J. Rösler2

1Nuclear Physics Institute ASCR, CZ-25068 Řež near Prague, Czech Republic

2TU Braunschweig, Institut für Werkstoffe, Langer Kamp 8, 38106 Braunschweig, Germany,

3IPM Brno, Czech Republic and TESCAN, a.s., Czech Republic

4TU München, Forschungsneutronenquelle Heinz Maier-Leibnitz (FRM II), Lichtenbergstraße 1, 85747 Garching, Germany

5Helmholtz Centre Berlin for Materials and Energy GmbH, Glienickerstr. 100, D-14109 Berlin, Germany

6Laboratory for Corrosion and Materials Integrity, EMPA Duebendorf, Switzerland

7Laboratory for Neutron Scattering, Paul Scherrer Institute, CH-5232 Villigen, Switzerland

strunz@ujf.cas.cz

Basic advantages and disadvantages of neutron radiation and its interaction with matter - with respect to materials research by means of neutron diffraction - are listed. The areas of Small-Angle Neutron Scattering (SANS) [1] application in materials science are discussed.

Several examples of the use of SANS to microstructural characterization of technologically important metallic materials are shown. First, a contribution of in-situ SANS to a solution of an open question in INCONEL polycrystalline superalloy load characteristics is reported. Secondly, evolution of γ’-precipitate morphology in pre-deformed single-crystal Ni-base superalloy at elevated temperatures is determined. Afterwards, characterization of a porous membrane prepared by selective phase dissolution process from the single-crystal Ni superalloy is presented. Further, SANS characterization of Ni3Si-type nanoparticles dispersed in a mixture of H2O/D2O using the contrast variation method is shown. Finally, the investigation of a model system (Al-Pb) for testing liquid-phase dispersion strengthening is discussed.

Precipitate

microstructure evolution in exposed IN738LC superalloy

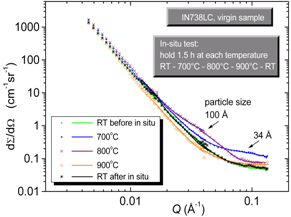

Nickel-base superalloy IN738LC has been studied after low-cycle fatigue by SANS [1,2]. Samples subjected to high-temperature low-cycle fatigue [4] were annealed at various temperatures to change the size and the distribution of precipitates. Ex- and in-situ SANS and high resolution TEM studies were performed. It was found by SANS that additional precipitates are produced either during slow cooling from high temperatures or after reheating above 570°C (Fig. 1). Their size and distribution were evaluated. The precipitates arise regardless the application of the mechanical load. Nevertheless, these small precipitates influence low-cycle fatigue resistance. From the SANS data, it can be also deduced that the equilibrium volume fraction of γ’-precipitates at temperatures from room temperature to 825°C is significantly higher than previously reported 45%. The kinetics of formation of small and medium-size γ’ precipitates at 700 and 800°C was determined as well.

Morphology

changes of γ' precipitates in pre-deformed single-crystal Ni-base superalloy

Exposure of a superalloy to an external load results in anisotropic coarsening of the γ’ precipitates (rafting). γ’ rafting can also occur as a result of purely thermal treatment, without the simultaneous presence of an external load, if the specimen has been pre-deformed at relatively low temperature. The evolution of γ’ morphology in pre-deformed specimens of SCA425 Ni-base superalloy was examined [5]. SANS data provide indication of rafting during the subsequent heating after severe compressive pre-straining (2%).

Pore

structure characterization in nanoporous membrane

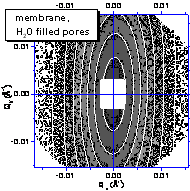

Using a selective phase dissolution technique, nano-porous membrane can be produced from simple two-phase metallic alloys. It contains through-thickness elongated channel-like pores of only a few hundred nanometer width and has a number of prospective applications. Knowledge of microstructural parameters is essential for membrane optimization. Non-destructive characterization of the pore microstructure was carried out by SANS technique [6]. The combined results from pinhole (Fig. 2) and double-crystal facilities enabled to determine microstructural parameters of the nanoporous membrane (pore-to-pore distance, raft thickness, pore volume fraction, specific interface). The contrast variation using D2O and H2O helped to conclude on scattering length density of both γ' pore walls as well as the original γ-phase matrix.

|

|

|

|

Figure 1. In-situ SANS for non-cycled sample: in-situ heating RT-700-800-900°C-RT (hold at each temperature during the in-situ SANS was always 1.5 hour). |

Figure 2. 2D cross-section dΣ/dΩ(Qx,Qy) is shown (left) for H2O filled pores of the porous membrane (scheme shown on right). The grey scale map shows measured 2D data and the white equi-intensity lines depict the fitted curves. V4 pinhole SANS, BENSC, HZ Berlin. |

Characterization

of core-shell nanoparticles

The Ni3Si-type nanoparticles dispersed in a mixture of H2O/D2O were characterized by SANS using the contrast variation method. The nanoparticles were produced by extracting precipitates from a bulk Ni-13.3Si-2Al (at.%) alloy using electrochemical phase separation technique and were pre-characterized by X-ray diffraction and transmission electron microscopy. The existence of a core-shell structure in the nanoparticles with a Ni3Si(Al) core and amorphous SiOx shell was confirmed by the SANS measurements [7]. By comparing the precipitate morphology in the Ni-Si-Al alloy with the extracted nanoparticles, it was clearly established that the size of precipitates is unaffected by the extraction process and that the amorphous shell forms on top of the particle core.

Metal-matrix

composite containing liquid-phase dispersion

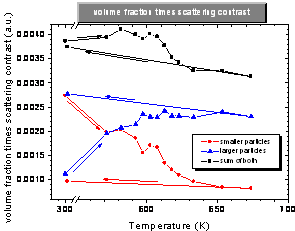

Al-Pb binary system is a suitable model system for testing liquid phase dispersion strengthening in bulk materials for structural applications. Liquid Pb islands can be finely dispersed in still solid Al matrix due to the substantial difference of melting points. The Al-Pb system prepared by means of Equal Channel Angular Pressing (ECAP) process was investigated by Small-Angle Neutron Scattering technique (SANS) which enables in-situ measurement of size and morphology parameters of Pb inclusions at elevated temperatures. It was observed that the lead particles were elongated roughly in the direction of ECAP [8]. During the subsequent in-situ thermal cycle RT-400°C-RT, the elongated Pb particles transformed to nearly spherical shape. The change of scattering contrast during melting of Pb mapped the transform of the confined lead particles to the liquid phase. The center of the transition region is around 342°C (615K) for both the as-cast and the ECAP deformed samples, which is a significant shift with respect to the free Pb melting point 327°C (600K). For the ECAP sample, the transition is not sharp, indicating a broad size distribution of lead particles (Fig. 3).

|

|

|

|

Figure 3. The temperature dependence of volume fraction times scattering contrast of confined Pb particles in the Al-4%Pb ECAP sample during the thermal cycle. |

|

References

1. G. Kostorz, in: Neutron Scattering (Treatise on materials science and technology), G. Kostorz (Eds.), Academic Press, New York, 1979, pp.227-289.

2. P. Strunz, M. Petrenec, U. Gasser, in Proceedings of the 15th International Small-Angle Scattering Conference, Sydney, Australia, 18-23 November 2012. D. McGillivary, J. Trewhella, E.P. Gilbert, T.L. Hanley (Eds.), Australian Nuclear Science and Technology Organisation, ISBN 1 921268 15 8, paperlessevent.com.au/SAS2012.zip

3. P. Strunz, M. Petrenec, U. Gasser, J. Tobiáš, J. Polák and J. Šaroun, submitted to Journal of Alloys and Compounds, 2013

4. M. Petrenec, J. Tobiáš, J. Polák, M. Šmíd, A. Chlupová, R. Petráš, in Proc. of XVI International Colloquium Mechanical Fatigue of Metals, J. Polák, T. Kruml, J. Man (Eds.), ISBN 978-80-87434-05-5, ÚFM AVČR, Brno, 2012, pp. 245-250.

5. P. Strunz, G. Schumacher, H. Klingelhöffer, A. Wiedenmann, J. Šaroun, U. Keiderling, J. Appl. Cryst. 44 (2011) 935–944.

6. P. Strunz, D. Mukherji, J. Šaroun, U. Keiderling, J. Rösler, Journal of Physics: Conference Series 247 (2010), 012023, doi:10.1088/1742-6596/247/1/012023.

7. P. Strunz, D. Mukherji, G. Pigozzi, R. Gilles, T. Geue, K. Pranzas, Appl. Phys. A 88 (2007) 277-284

8. P. Strunz, D. Mukherji, R. Gilles, T. Geue and J. Rösler, J. Phys.: Conf. Ser. 340 (2012) 012098, doi: http://iopscience.iop.org/1742-6596/340/1/012098

Acknowledgements.

The support by GACR project No. P204/11/1453 is gratefully acknowledged. The authors thank SINQ (PSI Villigen, Switzerland), NPL (CANAM), NPI Řež, Czech Republic) and BENSC (HZB Berlin, Germany) for providing beamtime and support for the SANS measurements. Infrastructure projects support (NMI3-II EC project No. 283883 and CZ MSMT project No. LM2011019) are gratefully acknowledged as well.