Cylindrical

image plate diffractometer – orienting and indexing of large compact samples

in reflection mode

Z. Matěj1, J. Šmilauerová1, J. Pospíšil1,

T. Brunátová1, P. Harcuba1, V. Holý1,

R. Kužel1

1Faculty of Mathematics and Physics,

Charles University in Prague,

Ke Karlovu 5, 121 16 Praha 2, Czech Republic

matej@karlov.mff.cuni.cz

Introduction

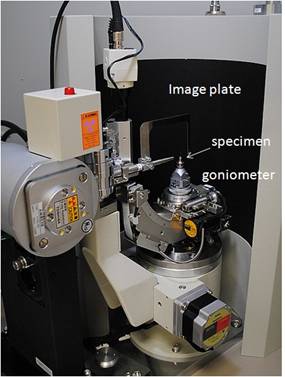

Rigaku RAPID II

installed in the X-ray lab at MFF UK [1] is a versatile diffractometer

proposing diverse options for material analysis by X-rays. It is equipped with a

three-axis goniometer and a large curved image plate (IP) detector. The

instrument can be routinely utilised for single crystal structure solution as

well as for powder diffraction. Residual stress or texture studies were also reported [2].

The aim of this contribution is a discussion of possibilities and limitations

of this instrument, which is not as common as the Bragg-Brentano or parallel

beam diffractometers. Its unique advantage, that large parts of the reciprocal

space are explored simultaneously, is illustrated on an example application of

the analysis of (coherent) inclusion nanoparticles in Ti-alloys.

|

|

|

|

Figure 1. Rigaku R-Axis Rapid II diffractometer with

image plate system. |

Figure 2. Florescent target mounted in the sample position.

During a typical experiment two goniometer axes are set to fixed positions (omega = 210°, psi = 55°) and the sample is

spinning/oscillating around the axis (phi)

perpendicular to the sample surface. |

Diffractometer,

large samples and reflection geometry

The

diffractometer is depicted in Fig. 1. Its standard applications include

analysis of small (~ 0.01-1 mm) single crystal samples or powders filled in glass/capton

capillaries. These experiments can be done directly in transmission geometry

and the advantage of the large cylindrical IP detector to capture a wide

range (~ 200°) of

scattering angles is fully utilised. Contrary, for large (~ 10 mm) compact samples of

a “coin” size and thickness, which are of main interest here, the

reflection geometry is the only reasonable option. A typical experiment is

depicted in Fig. 2. The sample surface is roughly aligned to be

perpendicular to the (phi) spin axis.

Other two goniometer axes (omega, psi) are set to general fixed positions.

A quick (20-30 min) “survey” experiment can be done with sample (phi) spinning or a series of pictures

can be acquired with crystal oscillating in small (phi) intervals during an “overnight” experiment.

|

|

|

Figure 3. Analysis of Debye rings from the NIST standard Si

powder sample for calibration of beam and sample displacement instrumental

corrections. Diffracted intensity in the bottom right corner of the IP is

shadowed by the goniometer head. |

Reference

samples

In order to

understand the diffraction geometry in detail and test the accuracy of the

experiment the NIST standard Si powder sample and a high quality defect free Si

wafer were measured under conditions described above. The analysis of the Debye

rings from the powder sample is illustrated in Fig. 3. In the first step

diffracted intensity at several (beta)

positions on the rings was fitted with Cu-Kalpha doublet profiles. The refined

experimental 2Theta positions were then

compared with that calculated for the nominal lattice parameter and including

zero-beam and sample displacement [3] corrections. This difference was smaller

than ~ 0.05° on all the Debye rings. If in addition the lattice parameter

was refined, the discrepancy from the nominal value was about ±0.001 Å.

For single crystal data the accuracy reached was slightly worth. About 15-40

diffraction maxima were analysed. The differences in 2Theta positions were practically same ~ ±0.05° and the (beta) positions on the rings were

predicted with ~ 0.1° error. Unfortunately the discrepancy in the lattice

parameter was ±0.003 Å for the single crystal experiments.

|

|

|

Figure 4. A preliminary analysis of the quick “survey”

measurement of the LCB beta-Ti alloy single crystal using the Rigaku 2DP software. Simulated green Debye

rings are related to the (bcc) beta-Ti matrix phase. Contrary red lines come

from the minor omega-Ti nanoparticles. The lattices of both phases are

coherent hence some beta-Ti green rings are overlapped with red rings of

(hexagonal) omega-Ti. |

Orienting and

indexing of single crystals of LCB Ti-alloy

Indexing of

LCB beta-Ti alloy [4] is a challenging problem. The single crystals

consist of a metastable bcc beta-Ti matrix and of a large fraction of

(coherent) inclusion nanoparticles of hexagonal-Ti. The samples were analysed

also by pole figures (PF) measurements and reciprocal space mapping in [5].

A preliminary

analysis of the quick “survey” experiment using the Rigaku 2DP software is

depicted in Fig. 4. Diffraction maxima from two different crystal systems

(bcc beta-Ti matrix and inclusion of hexagonal omega-Ti phase) are simply

identified. A large part of the reciprocal space is examined in this rapid

experiment. This is an advantage especially if we consider that e.g. for PF

measurements the line (2Theta)

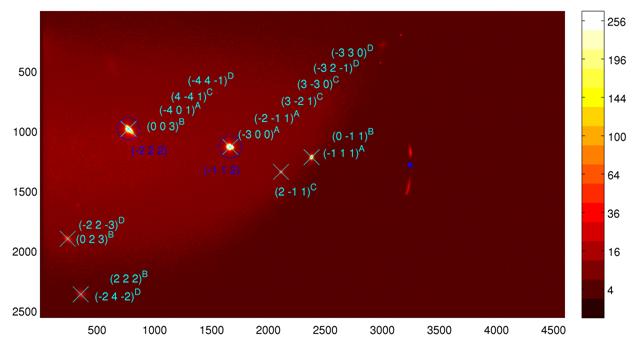

position must be known a priory. The longer “overnight” experiments

brilliantly simplify the orientation and indexing procedures and enhance signal

from weak diffraction maxima. An image from such a measurement is depicted in

Fig. 5. Finally it was indexed by the beta-Ti matrix and four families of

omega-Ti inclusions [5].

|

|

|

Figure 5. Possible indexing of an image taken in the

oscillation mode. Intensity maxima can be indexed by (bcc) beta-Ti matrix

(blue circles) and by 4 families (subindexes A, B, C, D) [5] of

(hexagonal) omega-Ti (cyan crosses). |

References

1. R. Kužel, Rigaku R-Axis Rapid II at MFF UK: http://www.xray.cz/kfkl-osa/eng/rapid/

(Jul 23, 2013).

2. M. Gelfi, E. Bontempi,

R. Roberti, L.E. Depero, Acta Mat., 52, (2004), 583.

3. N. V. Y. Scarlett,

M. R. Rowles, K. S. Wallwork, I. C. Madsen, J. Appl. Crystallogr., 44, (2011), 60-64.

4. J. Šmilauerová,

J. Pospíšil, J. Cryst. Growth,

(2013), submitted.

5. V. Holý, J. Šmilauerová,

J. Stráský, J. Pospíšil, M. Janeček, Mat. Struct. Chem. Bio. Phys. Tech., 20, (2013),

a contribution in these proceedings.

Acknowledgements.

This

work has been supported by the Grant Agency of the Czech Republic (project no.

P108/11/1539) and within the Charles University Research Center “Physics of

Condensed Matter and Functional Materials” (no. UNCE 204023/2012).