Toward the final explanation of martensitic transformation in shape memory alloy Co-Ni-Al

J.Kopeček1, M. Jarošová2, K. Jurek2, J.

Drahokoupil1, I. Kratochvílová1, L. Fekete1,

L. Bodnárová3, H. Seiner3, P. Sedlák3, M.

Landa3, J. Šepitka4, J. Lukeš4, V.

Kopecký1, O. Heczko1

1 Institute of Physics of the AS CR,

Na Slovance 2, 182 21 Praha

8, Czech Republic

2 Institute of Physics of the AS CR, Cukrovarnická 10/112, 162 00 Praha

6, Czech Republic

3 Institute of Thermomechanics

of AS CR, Dolejškova 5, 182 00 Prague 8, Czech

Republic

4 Laboratory of Biomechanics, CTU in

Prague, Technická 4, 166 07, Prague 6, Czech Republic

kopecek@fzu.cz

Great

success in Ni2MnGa derived alloys [1,2] attracted attention to similar Heusler alloys including cobalt based CoNiAl

and CoNiGa [3,4]. As the NiMnGa

alloys suffer due to their strongly intermetallic

state (brittleness, poor creep and fatigue properties) the cobalt based alloys

seemed to be the interesting candidate for the mechanically stronger and more

resistant FSMAs.

The article

describes the progress in work on Co38Ni33Al29

alloy [5,6]. The defined crystals with

single-crystalline matrix were prepared after long struggling. The influence of

annealing on martensitic transformation was

investigated. Both post-mortem XRD and in-situ neuron

diffraction confirmed the martensitic phase

transformation of alloy matrix B2 « L10 and stable amount of

A1 particles (fcc cobalt

solid solution) in alloy, Fig. 1. The image of transformation paths is blurred considering

the results of resonant ultrasound spectroscopy (RUS), magnetic susceptibility

measurements and various microscopies (LOM, SEM,

AFM), which shows transformation temperature significantly higher (about

approx. 70 °C). Without regard to structural confusion all samples perform pseudoelastic behaviour at room temperature, which is

strongly dependent on crystallographic orientation.

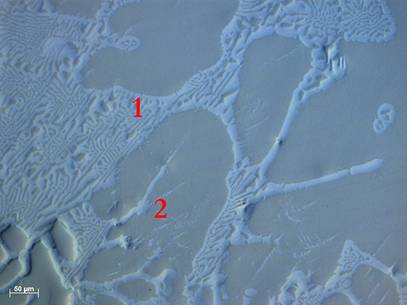

Figure 1. The structure of the samples observed by scanning

electron microscopy. The precipitates marked 1 are interdendritic

A1 fcc cobalt solid solution

particles. The precipitates marked 2 are L12 ordered precipitates of

the phase (Co,Ni)3Al.

Nevertheless,

the role of nanoprecipitates resulting from

segregation in oversaturated matrix after annealing

or other changes in matrix induced by quenching seems to be indisputable [7].

These precipitates can serve as nucleation centres for the stress induced martensitic transformation. Nanoprecipitates

were observed in annealed samples but in both pseudoelastic

[8] and non-pseudoelastic samples [9]. The wide

variety of nanoprecipitates is described in Ref. [4],

nevertheless their necessity for pseudoelastic

behaviour was not proven. The many micron-sized non-twinned, single and triple

{111}p twinned precipitates with partial L12 ordering

were observed in the austenite matrix after annealing at 1373 K for 72 h and

quenching [10]. The final description of A1 interdendritic

particles dissolution and the role of precipitation after quenching is still under the process.

The more

optimistic view we have now on various results of “transformation” given by

different methods. The strong magnetoelastic coupling

can be documented by the evolution of damping in RUS [11]. Surprisingly the

effect of magnetic field in Co-Ni-Al austenite, considering the external field,

is very weak [12]. We can expect now that the finalization of the oriented cuboid samples will give us the full elastic constants set

in temperature dependence and the story of “martensitic

transformation” in Co-Ni-Al alloys would be finally explained.

1. Heczko O., Scheerbaum N., Gutfleisch O., Magnetic Shape Memory Phenomena, in Nanoscale Magnetic Materials and Applications,

edited by J.P. Liu et al. (Springer Science+Business Media, LLC), 2009, pp. 14-1.

2. Heczko O, Sozinov A, Ullakko K, IEEE Trans.

Magn., 36, (2000), 3266-3268.

3. K. Oikawa, L. Wulff,

T. Iijima, F. Gejima, T. Ohmori, A. Fujita, K. Fukamichi,

R. Kainuma, K. Ishida, Appl.

Phys. Lett., 79, (2001), 3290.

4. Yu. I. Chumlyakov,

I. V. Kireeva, E. Yu. Panchenko, E. E. Timofeeva, Z. V. Pobedennaya, S.

V. Chusov, I.

Karaman, H. Maier, E. Cesari and V. A. Kirillov, Russ. Phys. J., 51, (2008), 1016.

5. J. Kopeček, S. Sedláková-Ignácová, K. Jurek, M. Jarošová, J. Drahokoupil, P. Šittner, V. Novák: Structure

development in Co38Ni33Al29 ferromagnetic

shape memory alloy, 8th th European

Symposium on Martensitic Transformations, ESOMAT

2009, edited by Petr Šittner,

Václav Paidar, Luděk Heller, Hanuš Seiner, 2009, article No. 02013.

6. J. Kopeček, K. Jurek, M. Jarošová, et al., IOP

Conf. Sci.: Mater. Sci. Eng., 7, (2010), 012013.

7. J. Kopeček, V. Kopecký, M. Landa, O. Heczko, Mat. Sci. Forum, 738-739,

416-420, (2013)

8. B. Bártová, N. Wiese, D. Schryvers,

N. J. Chapman, S. Ignácová, Acta

Mater., 56 (2008), 4470-4476.

9. B. Bártová, D. Schryvers, Z. Q. Yang, S. Ignácová,

P. Sittner, Scripta Mater.,

57 (2007), 37- 40.

10. J.B. Lu, H. Shi, S. Sedláková-Ignácová,

R. Espinoza, J. Kopeček, P. Šittner,

B. Bártová, D. Schryvers,

J. Alloys Comp., 572, 5-10, (2013)

11. H. Seiner, J. Kopeček, P. Sedlák, L. Bodnárová, M. Landa, P. Sedmák, O. Heczko, Acta Mater., 61, 5869-5876, (2013)

12. O. Heczko, H. Seiner, P. Sedlák, J. Kopeček, V. Kopecký, M. Landa, Eur. Phys. J. B, 86:(2),

62-1 – 62-5, (2013

Authors

would like to acknowledge the financial support from the Grant Agency of the AS

CR project IAA100100920 and Czech Science Foundation projects 101/09/0702, P107/11/0391.