Crystallization in sandwich nanocomposites of PE, PP and POM polymers

M. Šlouf, T. Vacková, H. Vlková, N. H. Vu, A. Sikora,

J. Kratochvíl,

H. Šandová, M. Steinhart

Institute of Macromolecular Chemistry, Academy of Sciences of the Czech Republic, Heyrovsky Sq. 2, 162 06 Prague 6, Czech Republic; slouf@imc.cas.cz

Keywords: sandwich nanocomposites, nanoparticles, titanium nanotubes, crystallization

Polymer nanocomposites are modern materials, formed usually by a matrix of synthetic polymer (such as polyethylene, PE, polypropylene, PP, polyoxymethylene POM…), which is filled with inorganic nanoparticles (such as oxides, metallic nanoparticles…). The inorganic fillers may influence mechanical, rheological, barrier and other properties of the final nanocomposite. In this study, we focus our attention on nucleation of polymer matrix crystallization: some nanoparticles act as nucleating agents, which means that the polymer spherulites start to grow on their surface. The nucleation effect impacts on the supermolecular structure of polymer matrix (spherulite size, overall crystalinity…) and on the crystallinity-related mechanical properties (modulus, yield strength…).

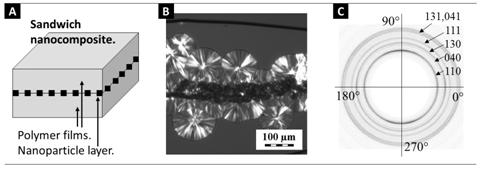

Figure 1. Principle of sandwich method: (a) Scheme of the sandwich nanocomposite. (b) PLM micrograph of the cross-section of PP/TiNT (where TiNT = titanium nanotubes) sandwich nanocoposite showing the PP spherulites growing from the central TiNT layer. (c) 2D-WAXS diffraction pattern of a sandwich nanocomposite, recorded with the beam going through the sandwich along the nanoparticle layer; the anisotropy in polymer crystallization due to nucleated crystallization demonstrates itself in the anisotropy of diffraction intensities.

In this work, we introduce the improvements in our recently developed sandwich method [1, 2]. We also summarize the results achieved for PE, PP and POM sandwich nanocomposites. The sandwich nanocomposites consist of thin (ca 100 micrometers) polymer plates, between which a thin homogeneous layer of nanoparticles is deposited (Fig. 1a). The nucleating activity of the nanoparticles can be studied by a number of methods, such as polarized-light microscopy (PLM; Fig. 1b), differential scanning calorimetry (DSC) and two-dimensional wide angle X-ray scattering (2D-WAXS; Fig. 1c). By means of model sandwich nanocomposites PP/Au and PP/TiX, where Au stands for several types of gold nanoparticles with different morphologies and TiX stands for various TiO2-based nanoparticles we proved that the nucleation activity is connected not only with the size, but also with the morphology and the agglomeration of the filler. The impact of filler morphology on its nucleation activity was observed also in PE/Au, PE/TiX, POM/Au and POM/TiX nanocomposites.

The sandwich method exhibits several advantages as far as the study of nucleating activity of micro- and/or nanoparticles in polymer nanocomposites is concerned: (i) The sandwich nanocomposites are small microscopic samples and, consequently, they are suitable for testing of small amounts of special nanocucleants. (ii) The preparation of sandwich nanocoposites, if performed carefully, is highly reproducible. (iii) The nanoparticles in sandwich nanocomposites do not suffer from agglomeration, which usually leads to not-very-well reproducible results in case of bulk-prepared nanocomposites. (iv) The combination of microscopic (PLM), thermal (DSC) and scattering (2D-WAXS) methods for characterization of crystal structure of polymer matrix in sandwich nanocomposites yields detailed insight into the nucleation activity of the studied nanoparticles.

References

1. E. Pavlova, M. Slouf, H. Sandova, J. Baldrian, A. Sikora, F. Lednicky, R. Masirek, E. Piorkowska, J. Macromol. Sci. Phys., 49, (2010) 392.

2. M. Slouf, A. Sikora, E. Pavlova, H. Vlkova, J. Baldrian, T. Base T, E. Piorkowska, J. Appl. Pol. Sci., (2012), in press, DOI 10.1002/app.36589.

Acknowledgements.

Financial support through projects GACR P205/10/0348 (Grant Agency of the Czech Republic) is gratefully acknowledged and AVOZ40500505(Academy of Sciences of the Czech Republic) is gratefully acknowledged.