Phase transformations of E110G Zr-alloy observed by “in-situ” XRD

J. Říha, P. Šutta

The most

important area of zirconium alloys usage is today the nuclear energetics. In

this sphere the zirconium alloys are mainly used as protective layers of

nuclear fuel rods where they create a first barrier against the reactor core

atmosphere. For this application the Zr-alloys must ensure a very low

absorption cross section for thermal neutrons, high corrosion resistance in

water steam at high pressure and temperature a good mechanical properties. In

this form these alloys are used in pressurized- and boiling-water reactors.

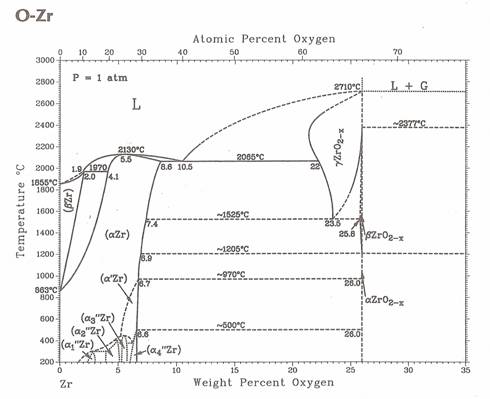

Except of those properties zirconium has a strong affinity for gaseous oxygen,

nitrogen and hydrogen with which they can form stable oxides, nitrides and

hydrides [1, 2]. Physical and mechanical properties of zirconium are influenced

especially by oxygen presence significantly. In form of solid solution oxygen and

also nitrogen stabilize the low-temperature a-Zr modification with HCP lattice and

also increase the zirconium hardness. The phase transformation temperature of pure

zirconium a ® b is

The development

of new Zr-alloys is in nowadays focused on their behaviour optimisation during

the Loss of Coolant Accident (LOCA). This type of reactor accident results in a

rapid moderator escape in time shorter than 10 seconds, followed by a rapid

heating of the Zr-alloy in steam environment at the temperature above

|

|

|

|

Figure 1. Zirconium – oxygen binary phase diagram. |

Figure 2. Zirconium – nitrogen binary phase diagram. |

The Zr-Nb

alloy E110G was used as an experimental material, Tab. 1. This material is today

most often used for nuclear fuel rods protective layers. With regard to

interstitial oxygen and nitrogen influence on phase transformations the samples

of pure Zr supplied by Goodfellow Ltd. were used for the comparison. During

previous experiments [4, 5] was observed, that the phase transformation of

zirconium to b-phase did not proceed even at

|

|

|

Figure 3. Heat treatment of experimental samples |

The XRD

measurements proceeded in high-temperature chamber Anton Paar HTK 1200N being a

part of automatic powder diffractometer Panalytical X’Pert Pro. This instrument

uses a copper X-ray tube (lKa = 0.15406 nm) and an

ultra-fast semiconductor detector PIXcel. The chamber was evacuated with the

aid of turbo-molecular pump Edwards EXT75DX. A dry scroll pump Edwards

XDS5 created the initial vacuum. For the lowest pressure achieving, the

deaeration step at

Table 1. Chemical composition of E110G Zr-Nb

alloy.

|

E110G Alloy |

Element |

|||||||

|

Nb [%] |

Fe [ppm/%] |

H [ppm] |

N [ppm] |

C [ppm] |

O [ppm] |

Ni [ppm] |

Hf [ppm] |

|

|

1,0 - 1,1 |

0,055 |

3 |

20 |

100 |

840 |

- |

~500 |

|

From the XRD results of both types of experimental

materials is evident that they contain a significant amount of nitrogen. This

element is in all samples in form of solid solution – diffraction patterns of

both samples in initial state show only a presence of a-Zr phase. The nitrogen causes an expressive increasing of a ® b phase transformation temperature,

Fig. 2.

A trace

amount of high-temperature b-Zr phase can be identified in E110G

alloy after heating at

|

|

|

|

Figure 4. Partial diffraction pattern of Zr-1Nb_12 |

Figure 5. Partial diffraction patterns of Zr_29 |

|

|

|

|

Figure 5. Partial diffraction pattern of Zr_29 during the heating. |

|

References

1. M. E. Dric,: Svojstva elementov, spravočnik,

Metallurgija Moskva 1985

2. J. Koutský, J. Kočík,: Radiation damage of structural materials. Praha Academia, 1994.

3. A. R. Massih, J. Nucl. Mat., 384, (2009), pp. 330–335

4. J. Říha, O. Bláhová, P. Šutta, Chemické listy, 105, (2011), pp. 210-213

5.

J. Říha, R. Medlín, A. Vincze,

P. Šutta, Vacuum, 86,

(2012), pp. 785-788