Structural and morphological properties of Fe2O3/TiO2

nanocrystals in silica matrix

Václav Valeš1,

Václav Holý1, Maja Buljan2, Vesna Janicki2,

and Sigrid Bernstorff3

1 Department of Condensed Matter Physics,

2

Rudjer Boskovic Institute,

3

ELETTRA Sincrotrone

Titania (TiO2)-based

systems have been very intensively studied in last decades because of their photocatalytic activity, which found broad commercial

applications. Functionalized titania

composites, especially Fe2O3/TiO2

systems attracted a lot of attention recently (see [1, 2], among others), since

they make it possible to improve the photocatalytic

performance of titania. The ε-phase of Fe2O3

exhibits a very large magnetic coercivity at room temperature [3] so that Fe2O3/TiO2

in solutions can easily be manipulated by external magnetic field. Fe2O3/TiO2

compact thin layer composites as a photocatalyst can respond to visible light

due to the narrow band-gap of Fe2O3.

We have studied two types of structures, namely (Fe2O3+SiO2)/SiO2

and (Fe2O3+SiO2)/ (TiO2+SiO2)/SiO2

periodic multilayers. Both types of samples were grown by a co-deposition of

the actual material together with SiO2 and pure SiO2 as

an interlayer spacer. The samples have been subsequently annealed for one hour

at various temperatures in air or forming gas (FG – Ar

+ 4% H2). We prepared a large series of samples with various thicknesses,

annealing temperatures and annealing atmospheres in order to find the optimal

conditions of the preparation; here we report only several characteristic

examples, their basic parameters are summarized in Tab. 1. Samples A – F

consist of 10 periods, samples A – C were annealed in forming gas atmosphere,

while samples D – F at the air. Samples that did not contain titania were prepared under various conditions – thickness

of Fe2O3+SiO2 layer from 0.6 nm to 2.0 nm, annealing temperature from 300 °C to 900 °C at air, forming gas, or vacuum. These samples

consisted of 20 periods.

X-ray diffraction curves of

the samples have been measured by laboratory diffractometer with a standard

x-ray tube (CuKa radiation, 1.5 kW)

using a parallel-beam setup. During the measurement the angle of incidence of

the primary beam was kept constant at 1 deg to suppress the substrate signal.

Small-angle x-ray scattering

in grazing incidence geometry (GISAXS method) has been carried out at ELETTRA

synchrotron source (SAXS beamline) using the photon energy of 8 keV. The incidence angle of the x-ray beam was chosen 0.25

deg, i.e. just above the critical angle of total external reflection.

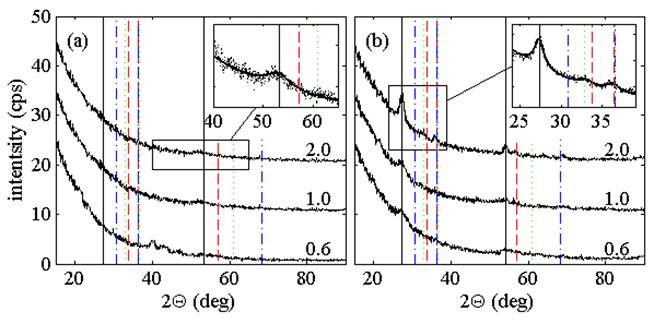

Figure

1. X-ray diffraction curves of samples A, B,

C (a) and D, E, F (b). The insets display the details of the diffraction peaks

along with their fits to theoretical curves (lines). The vertical lines

indicate the theoretical positions of the diffraction peaks for various phases:

black full line – rutile, red dashed line – hematite (a-Fe2O3),

blue dash-dotted line – maghemite (g-Fe2O3),

and green dotted - ε-Fe2O3.

The x-ray diffraction data on

samples without titania

exhibit diffraction maxima neither before, nor after post-growth annealing,

i.e., the Fe2O3

component did not crystallize under the annealing conditions used in this work.

The diffraction curves of samples A-F are presented in Figure 1. From the data

it follows that TiO2 nanoparticles grow during the annealing, from

the positions of their diffraction peaks we identified the tetragonal rutile

phase. More interestingly, in samples E and F we detected also Fe2O3

nanoparticles, however their diffraction maxima are

rather weak, which indicates that the density of these particles is very small.

The positions of the Fe2O3 maxima roughly correspond to

the hexagonal hematite a-Fe2O3

or ε-Fe2O3 phase. We have compared the diffraction

maxima with the simulations based on the Debye-formula approach [2] assuming

spherical particles and from this comparison we estimated the mean particles

sizes (Tab. 1).

Table

1. Parameters of the TiO2-containing

multilayers determined from x-ray diffraction and GISAXS methods, all values

are in nm. d is the nominal thickness

of layers, T is the annealing temperature,

RL, RV are lateral and vertical diameters of particles resp.,

aL,

aV

are mean base lateral and vertical vectors and σL, σV

are their rms.

|

Sample |

d |

T (°C) |

x-ray diffraction |

GISAXS |

||||||

|

RTiO2 |

RFe2O3 |

RL |

RV |

aL |

aV |

sL |

sV |

|||

|

A |

0.6 |

700 |

|

|

1.8 ± 1.0 |

1.8 ± 1.0 |

3 ± 3 |

10.0 ± 0.5 |

2 ± 1 |

5 ± 1 |

|

B |

1.0 |

700 |

|

|

2.5 ± 1.0 |

1.5 ± 1.0 |

3 ± 3 |

11.5 ± 0.5 |

2 ± 1 |

4 ± 1 |

|

C |

2.0 |

700 |

|

|

3.5 ± 1.0 |

1.5 ± 1.0 |

8 ± 3 |

12.5 ± 0.5 |

2 ± 1 |

4 ± 1 |

|

D |

0.6 |

900 |

1.6 ± 1.0 |

|

|

|

|

|

|

|

|

E |

1.0 |

900 |

2.1 ± 1.0 |

|

3.0 ± 0.5 |

2.0 ± 0.5 |

16 ± 5 |

10.0 ± 0.5 |

5 ± 1 |

5 ± 1 |

|

F |

2.0 |

900 |

3.2 ± 1.0 |

2.7 ± 1.0 |

5.0 ± 0.5 |

3.0 ± 0.5 |

16 ± 5 |

11.5 ± 0.5 |

5 ± 1 |

10 ± 1 |

From the fitting of experimental

GISAXS data we found that the (Fe2O3+SiO2)/SiO2

multilayers exhibit no diffraction peaks and no side maxima in GISAXS intensity

maps. Therefore, they remain amorphous and do not form any ordered

structure of amorphous or crystalline particles during post-growth annealing at

temperatures up to 900°C. On the other hand, the

multilayers (Fe2O3+SiO2)/(TiO2+SiO2)/ SiO2 exhibit

both diffraction peaks and GISAXS side maxima after annealing, thus they

contain ordered array of crystalline particles. In these samples, both rutile

TiO2 and hematite a-Fe2O3

are present, the latter with much smaller occurrence. Therefore, the presence

of the TiO2 phase facilitates the crystallization of Fe2O3

during post-growth annealing. Increasing the thicknesses d of the Fe2O3

and TiO2 layers, the mean lateral size of the particles increases;

the vertical size however remains almost constant so that the particles are

disc-shaped for larger d. A similar trend of increasing the lateral

particle size is observed for increasing annealing temperature. The number of

the observed diffraction peaks did not make it possible to determine the

lateral and vertical sizes. The particle size determined from diffraction is

affected by possible deformation of the particle lattice and/or by structural defects,

therefore a detailed comparison of the particle sizes determined from both

methods is not possible. Nevertheless, the particle sizes obtained from x-ray

diffraction and GISAXS data are not in contradiction.

References

1. H. Cui, W. Ren, W. Wang, J. Sol-Gel Sci. Technol. 58, 476 (2011).

2. V.

Valeš, J. Poltierová Vejpravová, V. Holý, V. Tyrpekl, P. Brázda, and S. Doyle,

phys. stat. solidi C 7, 1399 (2010).

3. J. Jin, K.

Hashimoto, and S. Ohkoshi, J. Magn. Magn. Mater. 15, 1067 (2005).

Acknowledgement.

The work was supported by the Czech Science Foundation (project

P204-11-0785) and by the Grant Agency of Charles University in