Investigations of real structure depth

distributions in metals

using diffraction techniques

Z. Pala

Department

of Solid State Engineering, Faculty of Nuclear Sciences and Physical

Engineering, Czech Technical University in Prague, Trojanova

13, 120 00 Prague 2, Czech Republic

zdenek.pala@fjfi.cvut.cz

In the case

of metals, X-ray diffraction (XRD) is often regarded as a surface technique

which reveals structural information about diffracting body only several

micrometers or tens of micrometers in thickness. Yet in comparison with

electron diffraction, assumption about surface sensitivity would be hardly

tenable. On the other end of the penetration scale, neutron diffraction is

firmly anchored because the neutrons penetrate metallic materials more easily

and the resulting data can be gained from depths amounting to centimetres.

Notion of penetration depth, which was

initially introduced by Cullity [1], is of vital

importance from the real structure point of view. The main reason is that metal

objects, especially those with surface treatment history, often show

significant depth gradients of macroscopic and microscopic residual stress,

grain sizes, or even texture. Gradients of these real structure characteristics

have direct impact on the object behaviour in real environment, affecting its

corrosion resistance, dynamic load stability, crack initiation and propagation

and other processes that can contribute to either prolongation or appreciable

shortening of fatigue life [2].

The effective penetration depth is

given by (i) absorption µ of the given volume for the impinging X-ray beam wavelength, (ii)

Bragg angle θ and (iii)

geometric alignment of the goniometer f(θ,ψ). Applying the well known Lambert-Beer

law for absorption, the ratio of intensities diffracted by a layer of thickness

dT

on the very surface and in the depth T

will be

. (1)

. (1)

Upon

setting this ratio to a convenient constant of 1/e and taking a logarithm of

the (1), the term for effective penetration depth Te is calculated:

. (2)

. (2)

Hence, Te determines the thickness

of a layer providing 63.2 % out of the entire diffracted intensity. Rigorously

said, the structural information gained from classical Bragg-Brentano goniometer or even grazing incidence diffraction changes

with the changing 2θ angle and

is, therefore, influenced by possible steep structural gradients. However, when

the gradients are not to be expected within the comparatively small thickness

comparable with Te, the

depth profiling can be performed with combining the chosen XRD technique on a

conventional laboratory diffractometers and

subsequent layer removal. Inherently destructive layer removal should be done

with minimal impact to the structure of the remaining layers; the most widely

used technique is electro-chemical polishing [3]. Even the laboratory diffractometers offer possibility to change X-ray tube and,

accordingly, the used wavelength. This would allow corresponding alteration of Te, yet given the variety of

X-ray tube selection, the scope of Te

for given metal is quite limited.

Another possibility for depth

distribution investigation in metals is to employ synchrotron radiation. Not

only is it tuneable with maximal energies peaking at 150 keV,

but the intensities increase manyfold. The

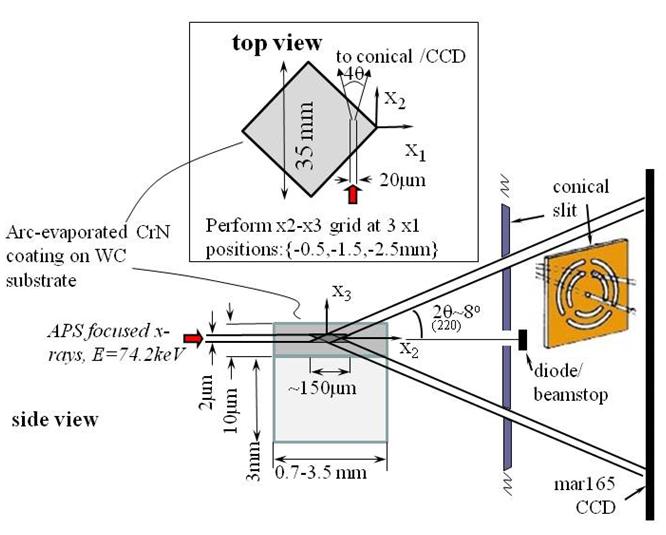

experimental set-up of 1ID C beamline at APS (Advanced Photon Source) in Argonne, USA

depicted in Fig. 1 is almost an ideal tool for defined depth profiling. The

incoming X-ray beam can be focused down to 2×5 μm2 and

with maximal energy of 130 keV can easily penetrate 1

cm of steel, with large detector array High Energy Detector Array or HYDRA© the

minimal acceptable transmission reaches 0.1 %.

Figure 1. Experimental set-up of 1 ID C in APS, Argonne; courtesy of Jonathan Almer.

The presentation will deal with detailed

description of advantages and pitfalls of diffraction experiment at 1 ID C. Furthermore, a mutual comparison

between conventional XRD laboratory and synchrotron experiment results will be

offered. Tangibly, macroscopic residual stress profiles in ground steel will be

compared. Moreover, depth distributions of structure in plasma sprayed tungsten

and copper layers used as plasma facing components in tokamaks

obtained with use of neutron diffraction [4]and synchrotron radiation will be

discussed.

Possibility to measure and study depth

distributions of real structures parameters represent a further step in the

progress of diffraction techniques and bring them nearer to the wider public.

In this case, the industrial applications are, indeed, numerous and

significantly broaden horizons of material scientists and physical engineers

during new material evolution and manufacturing of metal objects used in

hi-tech applications.

1. B.D. Cullity, Elements of X-ray diffraction. Reading:

Addison -Wesley. 1956.

2. A. G. Youtsos, Residual stress and its effect on fracture

and fatigue. Springer 2006.

3. S. Lee, Y. Lee, M. Chung, Metal removal rate of the electrochemical

mechanical polishing technology for stainless steel – the electrochemical

characteristics, IMechE Vol. 220, 2006.

4. V. Luzin, J. Matejicek, T. Gnaupel-Herold, Through-thickness Residual Stress

Measurement by Neutron

Diffraction in Cu+W

Plasma Spray Coatings,

Materials Science Forum 652 (2010) 50-56.

The

research was supported by the Project MSM 6840770021 of the Ministry of

Education, Youth and Sports of the Czech Republic and by the Project

SGS10/300/OHK4/3T/14 of the Czech Technical University in Prague.