Cobalt based ferromagnetic shape memory

alloys

J.Kopeček1,

M. Jarošová2, K. Jurek2, J. Drahokoupil1, I.

Kratochvílová1, L. Fekete1, L. Bodnárová3, H.

Seiner3, P. Sedlák3, M.

Landa3, J. Šepitka4, J. Lukeš4, O.

Heczko1

1 Institute of Physics of the AS CR,

Na Slovance 2, 182 21 Praha 8, Czech Republic

2 Institute of Physics of the AS CR,

Cukrovarnická 10/112, 162 00 Praha 6, Czech Republic

3 Institute of Thermomechanics of AS

CR, Dolejškova 5, 182 00 Prague 8, Czech Republic

4 Laboratory of Biomechanics, CTU in

Prague, Technická 4, 166 07, Prague 6, Czech Republic

kopecek@fzu.cz

Introduction

Ferromagnetic

shape memory alloys (FSMAs) took a lot of attraction in the

past decade [1]. The structural transition initialized by the magnetic field or

just shape change due to martensitic variant’s

reorientation give wide possibilities of applications as sensors or actuators. The NiMnGa based alloys were the most studied among FSMAs and they also

have the biggest potential. The ferromagnetic shape memory effect was described

in stoichiometric compound Ni2MnGa at first [2]. Later various

effects (as magnetically induced transformation or magnetically induced

reorientation) were described in non-stoichiometric alloys and shape change

grew from approx. 0,2 % for stoichiometric alloy up to 14 % in

off-stoichiometric one (for review see Ref. 1).

Great success in Ni2MnGa derived

alloys attracted attention to similar Heusler alloys including cobalt based

CoNiAl and CoNiGa alloys. As the NiMnGa alloys suffer due to their strongly

intermetallic state (brittleness, poor creep and fatigue properties) the cobalt

based alloys seemed to be the interesting candidate for the mechanically

stronger and more resistant FSMAs.

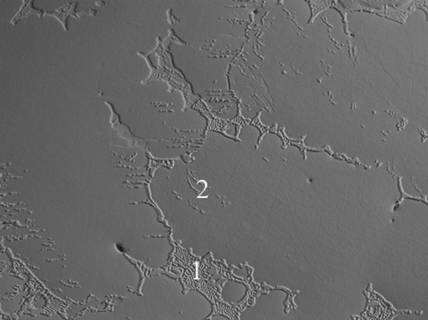

Figure 1.

The structure of the samples observed by light

microscope metallography. In B2 ordered matrix there are the precipitates - interdendritic

A2 fcc cobalt solid solution particles (marked 1) and the ordered precipitates

L12 of the phase (Co,Ni)3Al )marked 2).

The

presentation will describe the progress in work on Co38Ni33Al29

alloy. After long struggle we have managed to prepare the defined crystals with single-crystalline

matrix. The influence of annealing on martensitic transformation in these

crystals was investigated.

Structures

The

structure of the investigated material Co38Ni33Al29

is composed of three phases – an ordered matrix (Co,Ni)Al with space group Pm3m,

structure type B2, and a disordered face centred cubic cobalt solid solution

with space group Fm3m, structure type A2 [3], Fig. 1. According to the phase

diagram L12 structure (Co,Ni)3Al (space group Fm3m) exits

in samples with sufficient amount of nickel. The B2 phase matrix undergoes

martensitic transformation into the tetragonal L10 structure (space

group P4/mmm). The transformation mechanism is very similar to the Ni-Al alloy

including precursors, tweed structure and softening of the phonon modes [4].

The

structure analysis was performed using analytical electron microscopy including

electron back-scattered diffraction (EBSD) as our samples are usually

directionally crystallized structures with extremely large/coarse grains. The

set of the in-situ measurements as a function of temperature on powders was

performed on neutron source at HZB - E9 high resolution powder diffractometer.

Crystal

growth

In order to

study and to apply ferromagnetic shape memory effect (FSME), it is very convenient

to have single-crystalline samples. The samples for crystallization study were

prepared using vertical floating-zone method and Bridgman method [5, 6]. The

findings from it can be summarized in the points:

1.

The

samples grown with a growth rate of 17 mm×h-1 or lower have

tendency to get split into a two-phase mantle (B2 matrix plus A2 interdendritic

precipitates) and a single-phase (only B2) core. Such structures have tendency

to crack during cutting and polishing.

2.

The

composition of the matrix and precipitates seems to be stable within three

categories: Floating-zone sample; Bridgman sample grown with a growth rate of

17 mm×h-1 and Bridgman samples

grown with a growth rate higher than 17 mm×h-1. Both phases in

respective categories have the uniform composition. The last category appears

to be interesting for our investigation, since a variation of the chemical

composition along the Bridgman crystal is realized through the change of the

A2/B2 phase’s ratio.

Sample

annealing

A kind of

metastable (quenched) equilibrium is necessary for the SME performance in these

alloys. It was described in literature that this equilibrium can be reached by quick

cooling after homogenization annealing, but significant changes are observed

mainly in the matrix [7]. Nanoprecipitates of various phases are created by

quenching, which can later support spreading of the habit plane of martensite.

The fcc- and hcp-cobalt solid solution precipitates with a diameter below 100

nm were observed in samples grown with a growth rate 28 and 38 mm×h-1.[8, 9]. Other nanoprecipitates

were described in literature [7].

The

material is very sensitive to the annealing temperature. The sample’s phase composition change significantly as the composition of the

sample is driven by the

A2/B2 phase’s ratio and

annealing temperatures are close to the dissolving limit of A2 phase.

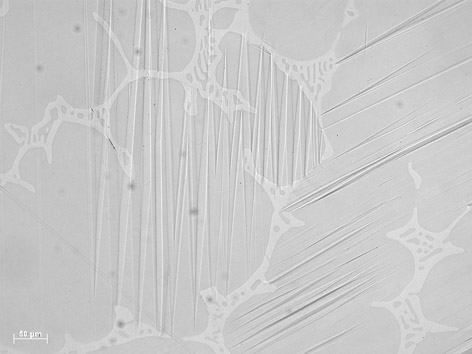

Martensitic

transformation

Older works

[10] reported quite high temperatures of the martensitic transformation, but

using magnetic susceptibility measurements we observed MS ~ −73

°C. The annealing temperature depends only slightly on annealing temperatures from

1250 °C up to 1350 °C. The hysteresis of the martensitic transformation enlarges

with decreasing of the annealing temperature. Although the martensitic

transformation was indicated by magnetic measurement at temperatures below −73

°C, the martensitic structures were observed in various samples at room

temperature. The small amount of martensitic lathes was observed in sample

annealed at 1250 °C, mainly in stressed areas close to

cracks. The sample annealed at 1350 °C contains compact areas of martensitic

lathes confirmed by EBSD. The complex interaction between martensitic lathes

and A2 particles was found. The martensitic lathes are partly pinned on the

grain boundaries and A2 particles, but some of them surround them developing

hierarchical structures close to particle’s surfaces in order to lower elastic

energy, see Fig. 2.

The

transformation temperatures obtained by magnetic susceptibility measurements do

not agree with the results of resonant ultrasound spectroscopy on the same

samples. This discrepancy will be discussed together with the results of the

quasistatic and dynamic nanoindentation.

Figure 2.

The sample annealed at 1350 °C for 1 h and

quenched to the ice-cold water. The martensitic lather are partially pinned on

the A2 particles and partially surround them.

References

1. Heczko

O., Scheerbaum N., Gutfleisch O., Magnetic Shape Memory Phenomena, in Nanoscale

Magnetic Materials and Applications, edited by J.P. Liu et al. (Springer Science+Business

Media, LLC), 2009, pp. 14-1.

2. Heczko O, Sozinov A, Ullakko K, IEEE Trans.

Magn., 36, (2000), 3266-3268.

3. M. Hubert-Protopescu, H. Hubert, Aluminium-cobalt-nickel

ternary alloys: a comprehensive compendium of evaluated constitutional data and

phase diagram. Vol. 4: Al-Cd-Ce to Al-Cu-Ru, edited by G. Petzow & G.

Effenberg (Weinheim: VCH ) 1991, pp. 234.

4. Y. Murakami, D. Shindo, K. Oikawa, R.

Kainuma, K. Ishida, Acta Mater., 50, (2002), 2173.

5. J. Kopeček, K. Jurek, M. Jarošová, et al., IOP

Conf. Sci.: Mater. Sci. Eng., 7, (2010), 012013.

6. J. Kopeček, S. Sedláková-Ignácová, K.

Jurek, M. Jarošová, J. Drahokoupil, P. Šittner, V. Novák: Structure

development in Co38Ni33Al29 ferromagnetic

shape memory alloy, 8th th European Symposium on Martensitic

Transformations, ESOMAT 2009, edited by Petr Šittner, Václav Paidar, Luděk

Heller, Hanuš Seiner, 2009, article No. 02013.

7. Yu. I. Chumlyakov, I. V. Kireeva, E. Yu. Panchenko,

E. E. Timofeeva, Z. V. Pobedennaya, S. V. Chusov, I.

Karaman, H. Maier, E. Cesari and V. A. Kirillov, Russ. Phys. J., 51,

(2008), 1016.

8. B. Bartova, D. Schryvers, Z. Q. Yang, S.

Ignacova, P. Sittner, Scripta Mater., 57, (2007), 37.

9. B. Bartova, N. Wiese, D. Schryvers, N. J.

Chapman, S. Ignacova, Acta Mater., 56, (2008), 4470.

10. K. Oikawa, L. Wulff, T. Iijima, F. Gejima, T.

Ohmori, A. Fujita, K. Fukamichi, R. Kainuma, K. Ishida, Appl. Phys. Lett.,

79, (2001), 3290.

Acknowledgements.

Authors

would like to acknowledge the financial support from the Grant Agency of the AS

CR project IAA100100920 and Czech Science Foundation projects 101/09/0702 and

P107/10/0824.