Fe2O3/SiO2

Nanocomposite – Shape of the e-Fe2O3 Nanocrystals

P. Brázda1, M. Klementová1 and D. Nižňanský2

1Institute of Inorganic Chemistry of

the AS CR, v.v.i., 250 68 Husinec-Řež 1001, Czech Republic

2Dept. Inorg. Chem., Faculty of

Science, Charles University in Prague, Hlavova 8,

12843 Prague 2, Czech Republic

brazda@iic.cas.cz

The

first article dealing with the e-Fe2O3

was published in 1934 [1]. However, its crystal structure described in the

orthorhombic Pna21 was published in 1998 [2]. The structure

of epsilon phase is characterized by the closest packing of the oxygen anions

with ABAC stacking. The stacking planes are parallel to (001). The iron cations

occupy four different sites. Three of them have octahedral and the last one has

tetrahedral coordination polyhedron. The values of the lattice constants are a

= 5.091 Å, b = 8.784 Å and c =

9.472 Å. After a discovery of its giant 2 T room temperature

coercivity in 2005 [3] the epsilon phase attracted more attention as these

properties predestinates it as a promising material for magnetic recording and

information storage. Moreover, in 2009 Namai et al. used this phase as a

high-performance millimeter electromagnetic wave absorber, which opens a

possibility of the applications of this material in high-speed wireless

communication devices [4].

Nanocomposites were prepared by a sol-gel process using complex molecule

of ferric cation and organic molecule H2L bearing two

trimethoxysilyl groups (H2L = bis-[3‑(trimethoxysilyl)propylamide]

of ethylenediaminetetraacetic acid). After hydrolysis and condensation of

Si-OMe groups followed by drying, the xerogels obtained were annealed at final

temperatures between 900 to1100 °C, thus obtaining nanocomposites with 40%

weight concentration of iron oxide [5]. The SiO2 matrix was removed

by reacting the nanocomposite with 5 M NaOH at 80 °C for three days.

The nanocrystals were then washed several times by distilled water and

collected by centrifugation. The transmission electron microscopy (TEM)

measurements were conducted using a JEOL JEM-3010, while the X-ray diffraction (XRD) data were collected using a

PANalytical X’Pert Pro with Cu Ka radiation (λ =

1.5418 Å) at room temperature with the 2θ range between

10° and 110°. Rietveld analyses were performed by the Fullprof program [6]. As

a profile function was used Thompson-Cox-Hastings pseudo-Voigt function. For a

modeling of the anisotropic shape of the crystallites were used spherical

harmonics.

The epsilon phase is stable only in a restricted size range between

approximately 10 to 100 nm. It crystallizes in the Fe2O3/SiO2

system from maghemite and transforms to thermodynamically stable hematite under

prolonged heat treatment. The shape of the epsilon phase crystals depends on

the size of the crystals. The particles obtained at 1100 °C adopt a

disc-like shape flattened in c direction with similar diameters in a

and b directions and they are in almost all cases single crystals. The

largest crystal faces are (001) and (110) as deduced from the HR-TEM images.

These results are in an agreement with XRD data fitting (Figure 1). Table 1

summarizes the volume weighted diameters in the [100], [010] and [001] of the

coherently diffracting domains of the epsilon phase. The fastest growth of the

crystals in the temperature range between 900 °C and 1100 °C is in

the [001] followed by the [100]. The smallest growth is in the [010]. It is

important to note that the viscosity of the silica matrix significantly

increases at about 1000 °C. Under this temperature the growth of the

particles is much slower. To understand this anisotropic growth of the epsilon

crystals it is necessary to understand the basics of the epsilon transformation

from maghemite.

Maghemite has a spinel structure, which is described in the cubic space

group ![]() . The stacking of the oxygen anion layers is along

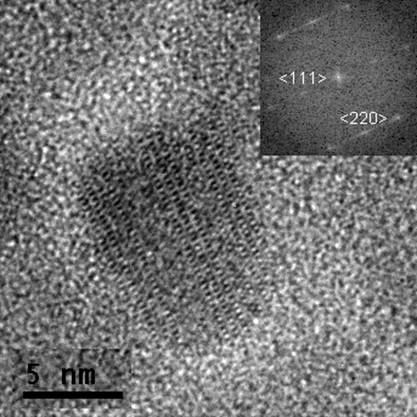

<111>. The maghemite particles with the size close to 10 nm are

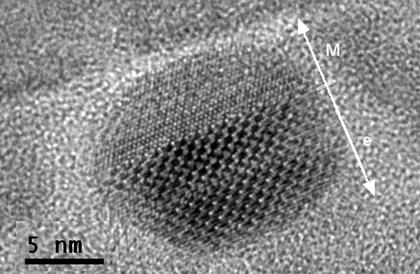

flattened in one of the <111> directions (Figure 2). Some particles

contain domains of both maghemite and epsilon. The contact plane of these

phases was found to be <111>M/[001]e. Evaluation of the FFTs of the HR-TEM images showed that there is a

fixed structural orientation relationship between these two phases (<110>M

is parallel to [010] e and <211>M

is parallel to [100]e, Figure 3). This

orientation relationship is the same as that found by Ding et al. for magnetite

and epsilon [7]. Interestingly, the nanowires of magnetite described in this

work transformed in the epsilon phase only in case when the nanowires grew

along one of the <110> of magnetite (which is the same direction as the

<110> of maghemite), which could explain why is the largest diameter of

the smallest epsilon particles is in the [010]e.

. The stacking of the oxygen anion layers is along

<111>. The maghemite particles with the size close to 10 nm are

flattened in one of the <111> directions (Figure 2). Some particles

contain domains of both maghemite and epsilon. The contact plane of these

phases was found to be <111>M/[001]e. Evaluation of the FFTs of the HR-TEM images showed that there is a

fixed structural orientation relationship between these two phases (<110>M

is parallel to [010] e and <211>M

is parallel to [100]e, Figure 3). This

orientation relationship is the same as that found by Ding et al. for magnetite

and epsilon [7]. Interestingly, the nanowires of magnetite described in this

work transformed in the epsilon phase only in case when the nanowires grew

along one of the <110> of magnetite (which is the same direction as the

<110> of maghemite), which could explain why is the largest diameter of

the smallest epsilon particles is in the [010]e.

In conclusion the transformation of maghemite to epsilon is probably

much faster within a cationic layer than in the direction perpendicular to the

atom stacking as evidenced by the different growing rate of the epsilon phase

in the a, b and c directions.

Figure 1 Comparison of modeled anisotropic

crystal shape (left) with crystals viewed along the corresponding directions in

the HR-TEM images (right) of the sample annealed at 1100 °C.

Figure 2 HR-TEM image of a maghemite

particle observed along <211> direction.

Figure 3 HR-TEM image of a particle

containing both maghemite and epsilon. Arrow points in [111]M and

[001]e. Perpendicular to this direction is

<110>M//[010]e.

Table 1 Volume weighted diameters on e-Fe2O3

as a function of the annealing temperature.

|

Temperature |

[100] |

[010] |

[001] |

|

900 |

6(1) |

11(1) |

3(1) |

|

950 |

10(1) |

10(1) |

5(1) |

|

1050 |

28(2) |

24(2) |

17(2) |

|

1100 |

41(3) |

40(3) |

27(3) |

1. H. Forestier

& G. Guiot-Guillain, C. R. Acad. Sci. (Paris), 199 (1934) 720

2. E. Tronc, C.

Chanéac & J. P. Jolivet, J. Solid State Chem., 139 (1998)

93-104

3. J. Jin, K.

Hashimoto & S. Ohkoshi, J. Mater. Chem., 15 (2005) 1067-1071

4. A.

Namai, S. Sakurai, M. Nakajima, T. Suemoto, K. Matsumoto, M. Goto, S. Sasaki

& S. Ohkoshi, J. Am. Chem. Soc., 131(3) (2009) 1170-1173

5. P. Brázda, D. Nižňanský, J.-L. Rehspringer & J. Poltierová Vejpravová, J.

Sol‑Gel Sci. Technol., 51 (2009) 78-83

6. J.

Rodriguez-Carvajal, Physica B, 192 (1993) 55-69

7. Y. Ding, J. R. Morber, R. L. Snyder & Z. L.,

Wang Adv. Funct. Mater., 17 (2007) 1172-1178