Defect Determination in Epitaxial a-plane GaN Layers

Mykhailo Barchuk,a Václav Holý,a Dominik Kriegner,b

Julian Strangl,b Stephan Schwaiger,c and Ferdinand Scholzc

a Charles University in Prague, Czech Republic.

b Johannes Kepler University, Linz, Austria.

c Ulm University, Germany.

E-mail: mikebarchuk@rambler.ru

Technological applications of optoelectronic devices based on (0001), i.e., c-oriented GaN are complicated by the piezoelectric effect along the [0001] direction. This phenomenon gives rise to a band bending, known as the quantum confined Stark effect [1].

Non-polar or semipolar GaN thin films overcome this problem. However, this type of material possesses a large number of defects, especially stacking faults (SF) so that a reliable method for the determination of the defect densities is of large importance.

We investigate non-polar a-plane oriented GaN epitaxial layers with the (11-20) surface orientation.

In the layers of a-plane GaN, two types of basal

plane stacking faults with the displacement vectors R = 1/6![]() and 1/3

and 1/3![]() are the most typical defects [2]. Another defect types

(extrinsic basal stacking faults with R=1/2(0001), prismatic stacking

faults with R=1/2

are the most typical defects [2]. Another defect types

(extrinsic basal stacking faults with R=1/2(0001), prismatic stacking

faults with R=1/2![]() ) can also occur but their formation energy is significantly

higher so that one can neglect their influence [3].

) can also occur but their formation energy is significantly

higher so that one can neglect their influence [3].

For the detection of SFs by x-ray

diffraction, the visibility criterion can be applied. If g.R

¹ n (g is the diffraction vector, n is an integer), the

diffuse x-ray scattering from the SFs has the form of [0001]-oriented streaks

perpendicular to the fault planes; if g.R

= n the defects are generally invisible by x-ray diffraction [4]. In the latter

case, (for example in ![]() diffraction) a

broadening of the diffraction maximum is observed caused by another defects

such as dislocations, wafer curvature, and surface roughness.

diffraction) a

broadening of the diffraction maximum is observed caused by another defects

such as dislocations, wafer curvature, and surface roughness.

We investigated a series of 4 samples grown by MOVPE technique [5] with various densities of stacking faults.

The x-ray diffraction (XRD) measurements were performed using a custom built rotating anode setup. A double bent parabolic multilayer mirror and a Ge(220) channel cut monochromator were used to produce a parallel beam of CuKα1 radiation. The diffracted radiation was measured by a linear multichannel detector.

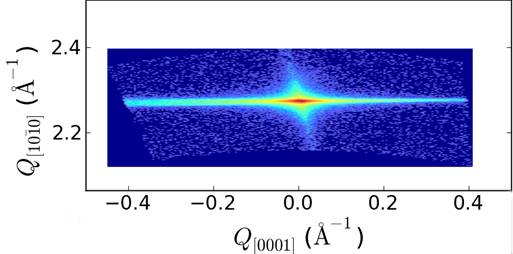

The reciprocal space maps of diffracted

intensity were measured in a non-coplanar Bragg geometry. In order to reach the

diffractions ![]() and

and ![]() , in which the visibility criterion is fulfilled, and using

the scattering plane containing the [0001] streak direction, this scattering

plane had to be tilted by 30 deg with respect to the surface normal. In this tilted

plane, diffractions

, in which the visibility criterion is fulfilled, and using

the scattering plane containing the [0001] streak direction, this scattering

plane had to be tilted by 30 deg with respect to the surface normal. In this tilted

plane, diffractions ![]() and

and ![]() are symmetric. In

are symmetric. In ![]() and

and ![]() diffractions we were

able to observe the [0001]-streaks arising from the various types of SFs

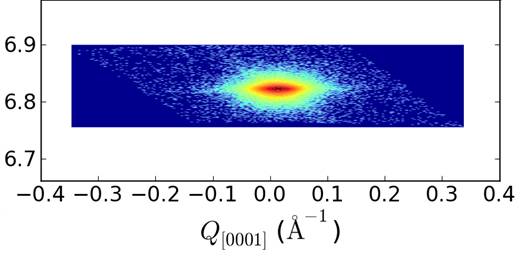

(Fig.1). For comparison, we measured also the reciprocal space maps in

diffractions we were

able to observe the [0001]-streaks arising from the various types of SFs

(Fig.1). For comparison, we measured also the reciprocal space maps in ![]() , where the visibility criterion is not fulfilled. In this

diffraction, the SF-related streak does not appear indeed (Fig.1, the right

panel).

, where the visibility criterion is not fulfilled. In this

diffraction, the SF-related streak does not appear indeed (Fig.1, the right

panel).