Laboratory Rotan

Z. Šourek

Institute of Physics, Academy of Sciences of the Czech Republic, v.v.i., Na Slovance 2, 182 21 Praha 8, Czech Republic

sourek@fzu.cz

The current Laboratory Rotan (Fig. 1) in the Institute of Physics, Academy of Sciences of the Czech Republic, v.v.i., was established in 1992 when the first X-ray generator with rotating anode in the Czech Republic was put into operation. The staff of the new laboratory was put together from members of the reputable X-ray laboratories founded by A. Kochanovská, R. Bubáková or M. Polcarová. I would like to devote several words to remind these personalities in the first part.

Figure 1. Laboratory Rotan in the Institute of Physics, Academy of Sciences of the Czech Republic, v.v.i.

The enormous importance of A. Kochanovská for the Czech crystallography generally and for the industrial applications of the X-ray diffraction in particular is well known. She was the head of the X-ray microstructure analysis department in the Research Institute of Physics of Skoda Works since 1935. Several years later this unit was integrated into our institute and she continued with her scientific work there till 1968. Her successors were J. Čermák [1] and later today’s Rotan staff member M. Čerňanský.

R. Bubáková gave the first experimental evidence of the validity of the dynamical X-ray diffraction theory. Publications Bubáková – Drahokoupil – Fingerland [2] on the theory and applications of the double and triple crystal diffractometers came to be one of the essential pillars of the field known at the present as high resolution X-ray diffraction. The students of R. Bubáková, O. Pacherová and Z. Šourek, are also engaged in the today’s Rotan laboratory.

M. Polcarová was internationally recognized expert in the field of X-ray diffraction topography. Her discovery of previously unobserved magnetic domain structures [3] got into the textbooks.

The laboratory is now equipped with two X-ray generators with rotated anode. The new diffractometer Bruker D8 DISCOVER SUPER SPEED SOLUTION has been purchased two years ago. It is furnished with the rotating anode TURBO X-RAY SOURCE providing up to 18 kW of power. On hand is Cu anode with line focus only. The Eulerian cradle and the cooling stage Anton Paar DCS 350 with the temperature range from -100 °C to +350 °C are available, too. The modular concept (horizontal θ/2θ goniometer, parabolic Göbel mirror, two different Bartels monochromators based on Ge single crystals, two analyzers of the diffracted beam - the LiF single crystal monochromator of the diffracted beam, and the two-beam analyzer PATHFINDER based on Ge single crystals, and the dynamic scintillation NaI detector) allows its using for high-resolution X-ray diffraction, X-ray reflectometry, texture and stress analyses, and for standard powder diffraction with the parallel beam geometry. The interpretation of the experimental results can be made easily by the software packages TOPAS for quantitative phase analysis of polycrystalline materials and LEPTOS - the unified and self-contained software for the analysis of X-ray reflectometry, high-resolution X-ray diffraction including grazing-incidence diffraction, and residual stress.

Apart from the new diffractometer, a high-resolution X-ray goniometer Bede 200 equipped with the triple-axis stage on the detector axis and HUBER goniometer supplied with the parallel beam arrangement together with the X-ray sensitive TV camera and appropriate detectors are also available. Both last-named goniometers are used with the 18 kW rotating anode X-ray generator Rigaku RU 300 produced in 1992. For this facility several anodes giving a wide range of wave lengths and also several focus sizes are available.

We have also a conventional X-ray powder θ/θ diffractometer X’Pert PRO from PANalytical which is a flexible instrument equipped with Co anode. The ultra rapid X’Celerator detector enables very fast and precise phase analysis and size-strain determination. A parabolic mirror and a parallel plate collimator are useful preparatives in the case of a rough sample surface, in a study of thin layers and in the determination of macroscopic residual stresses. The ATC-3 cradle can undertake texture determination. This equipment also enables the measurement of macroscopic residual stresses in ψ-geometry and particular studies of single crystals. The high temperature chamber Anton Paar HTK2000 enables measurement under vacuum 10-4 mbar to 2300 °C. The measured data are processed by several software programs from X'Pert HighScore Plus used to phase analysis and Rietveld refinement, continuing by program Topas for Rietveld analysis enabling a precise description of instrumental profiles and determining a microstrain and a crystallite size.

Another powder diffractometer is furnished with a unique high-angle monochromator in the primary beam. It considerably narrows the spectral interval of the X-ray radiation and thus enables the significant enhancement of the accuracy and the angular resolution of diffraction line profile measurements. This arrangement is operated by the high performance 3 kW Seifert X-ray generator ISO-DEBYFLEX 3003. The crystal orientation is performed by the Laue technique, the source is the Seifert X-ray generator of the same type with W anode. A free Orient express program is used for interpretation.

The joint Laboratory Rotan cooperates with almost all sections of the institute and contributes to further technological research in many fields. In this laboratory, the structural problems of various branches of physics of condensed matter are solved in a wide spectrum of materials by different and often unique X–ray techniques. There are studied relations between structural properties of materials, technologies of their preparation and their mechanical, electrical, and optical properties and finally their suitability for practical application.

We are taking part in many projects. In the case of polycrystalline materials it often concerns the determination of the grain size, crystal phase ratio, recently also texture analysis, but primarily the quantitative phase analysis takes place, most frequently in the connection with thin layers preparation.

X-ray phase analysis can substantially help during the process of preparation of hard and superhard TiN nanocomposite coatings both by the low-energy ion bombardment and the excimer laser ablation. The latter technology supplies us with a lot of samples including biocompatible materials and the influence of different growth conditions could be observed. On the basis of our measurements the first demonstration of the possibility to prepare the single thermoelectric layer with the high figure of merit ZT by laser ablation was given [4]. The result is i.a. explained by the fact that the layers consist of a few certain phases of the Bi2(m+n)Te3n type. We characterise also ferroelectric layers prepared by the sol-gel method and nanoscopic ferroelectrics as well as nanoscopic ferromagnetic films. Systematical attention is paid to the real structure of surface of mechanically treated steel as well as depth gradients of macroscopical strain, crystallite size and microstrains [5]. Complex structural analysis of stresses caused by surface machining of iron materials were performed by the precise and quick phase analysis. By the same method we follow the changes of martensitic and austenitic phases in the intermetalic compounds exhibiting shape memory effect. The amorphous phase ratio of metal glasses, isostructural glasses, crystals and glass-ceramic composites for optoelectrical applications were also determined.

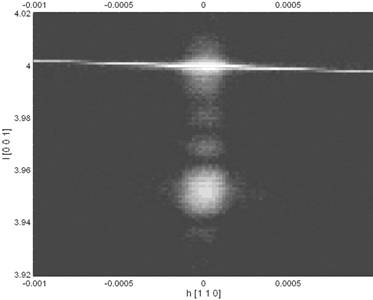

As regards single crystal investigations we can use high resolution X-ray diffraction and X-ray reflectometry. Implicit advantage of the high resolution X-ray diffraction consists in its remarkable sensitivity for exceptionally small lattice deformations. We studied semiconductor superlattices grown on the intentionally off-cut GaAs substrates. Off-cut angle as well as lateral periodicity of the interface steps was identified. At present a great attention is paid to GaMnAs (Fig. 2) since - thanks to its unique properties - it is a promising material for prospective spintronic applications. The determination of Mn atom sites in the GaMnAs unit cell, which essentially affects properties of this material, is the recent topic of many projects [6]. Also the structural investigations of bulk GaN crystals are in progress. X-ray reflectometry, surface-sensitive analytical technique used to characterize surfaces, thin films and multilayers, is a very useful tool for the determination of surface and interface roughness, average multilayer density, etc. Mainly metal and semiconductor multilayers with imperfect interfaces are studied by this way.

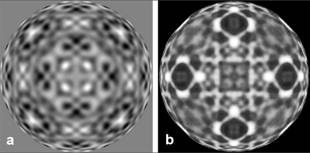

Though very intensive X-ray sources are available in the Laboratory Rotan we welcome to join projects with the use of synchrotron radiation. We perform both necessary preliminary experiments in the home laboratory and took part in the synchrotron radiation experiment itself, usually in ELETTRA or ESRF (Fig. 3). Also new X-ray optic elements for use by synchrotron radiation facilities are checked in our laboratory.

The group also cooperates on development of novel techniques used in X–ray analysis, presently for example on the development of X–ray holography with atomic resolution [7].

Figure 2. The reciprocal space map in the vicinity of the symmetrical (400) reflection of GaMnAs / GaAs sample with the 49 nm thick layer, CuKa radiation.

Figure 3. Comparison of the absorption holograms of 300 mm silicon wafer exposed in the Laboratory Rotan by 8 keV (a) and at the synchrotron radiation source Elettra by 14 keV (b).

References

1. J.

Čermák, J. Phys. E, 3, (1970), 615.

2. R. Bubáková, J. Drahokoupil, A. Fingerland,

Czech. J. Phys B., 11, (1961), 199.

R. Bubáková, J. Drahokoupil, A. Fingerland, Czech. J. Phys B., 12, (1962), 764.

3. M. Polcarová, A. R. Lang, Appl. Phys.

Let., 1, (1962), 13.

4. J. Walachová, R. Zeipl, J. Zelinka, V.

Malina, M. Pavelka, M. Jelínek, V. Studnička, P. Lošťák, Appl. Phys. Lett.,

87, (2005), 81902.

5. J. Drahokoupil, N. Ganev, M. Čerňanský, P.

Boháč, R. Čtvrtlík, M. Stranyánek, Z.

Kristallogr. Suppl., 27, (2008),

89.

6. V.Holý, Z.Matěj, O.Pacherová, V.Novák, M.Cukr,

K.Olejník, T.Jungwirth, Phys. Rev. B, 74, (2006),

245205.

7. M. Kopecký, E. Busetto, A. Lausi, Z. Šourek,

J. Kub, M. Cukr, V. Novák, K. Olejník, J. P. Wright,

J. Appl. Crystallogr. 41, (2008), 544.

Acknowledgements.

The cooperation of O. Pacherová, J. Drahokoupil, and J. Kub, my colleagues from Laboratory Rotan, in the preparation of this contribution is gratefully acknowledged.