X-ray

diffraction determination of pearlitic steel properties

(Sledování vlastností pearlitické oceli v rtg. difrakci)

D. Šimek1,

D. Rafaja1, M. Motylenko1, V. Klemm1,

G. Schreiber1,

G. Lehmann2, R. Schmidtchen2, A. Oswald2

1TU-Bergakademie

2TU-Bergakademie

simek@fzu.cz

Introduction

Ferrito-pearlitic

steels are ones of the mostly produced materials for common industrial and

construction purposes. The properties of the steel do not depend only on its

chemical composition, but on the preparation, i.e. the thermo-mechanical

history, leading to a different microstructure. The steel is easily-formable at

higher temperatures (above 911 °C), when the structure of the steel is fcc

cubic (austenite), the recrystallization and recovery takes place and the

deformability is practically unlimited. At lower temperatures, primary ferrite

(bcc cubic) phase starts to nucleate at grain boundaries, expelling the

excessive carbon into the austenite. The amount of primary ferrite depends on the

amount of carbon, on the time for which the material is held above the

eutectoid temperature (727 °C) and on the grain boundary surface too

(cross-section for the diffusion process). The rest austenite decomposes below eutectoid

temperature into a mixture of two stable phases – ferrite and cementite

(orthorhombic Fe3C). The transformation is of displacive nature

(martensitic) but employing a diffusion of excessive carbon away from the newly

self-forming ferrite phase. Depending on the undercooling, the transformation

occurs during a limited time span, which limits an effective distance the

diffusion can affect. The resulting microstructure thus differs from dendritic structure

or needle-shaped bainite (for faster cooling) to a lamellar structure called

pearlite (slower cooling). The thickness of the lamellas is inversely

proportional to the undercooling [1].

Mechanical

properties

The mechanical

properties of the resulting pearlite can be roughly described as follows: The

yield stress of pearlite is inversely proportional to a certain power of its

interlamellar spacing S:

![]() . (1)

. (1)

The equation is referred to as

Hall-Petch relationship and originally describes an enhancement of the yield

stress with the refinement of the grains (mh = 1/2).

The extrapolation to an infinitely thick lamellas s0 yields negative values for mh = 1/2,

thus mh = 1 is usually considered. Alternatively an

expression based on the dislocation motion in within lamellas was derived [2],

where s ~ S–1ln(SVa/b), b

is the Burgers vector and Va a volume portion of ferrite in

pearlite. This expression is equivalent to (1) and mh = 1

for large S and deviates towards mh = 1/2

for thinner lamellas. The past studies of fully pearlitic eutectoid and

hypereutectoid (carbon content ≥ 0.73 wt.%) steels [3, 4] with

experimental values of S typically ranging from 150 to 250 nm did

not allow to determine properly the nature of the dependence.

The behaviour of the hypoeutectoid

(carbon content < 0.73 wt.%) steel is even more complex, as it is

a composite formed from primarily crystallized ferrite grains with a size at

the order of microns and the pearlitic colonies of similar size (several

microns). The combination of micro- and nano-scale originated effects

superimpose and the early investigations of yield stress [3] were not much

successful in description of the composite behaviour. Recently, self-consistent

simulation procedures were introduced [5], which allow modeling of the

stress-strain curves at higher stages of deformation at least.

Experimental

The samples

were hot-rolled under different temperatures in an industrial type of rolling

stage with one to 14 passes through the rolls. After the rolling, the resulting

circular or elliptical profile was cooled down either on the air, in the water,

in a molten lead bath or their combination (e.g. first rest on the air, then

lead bath). The aim was to produce a variety of microstructures with different

mechanical properties. Specimen of the resulting materials were cut (both

normally and laterally), embedded into a resin matrix, ground, polished and

etched. The resulting surface (originally inside the profile) was investigated

by means X-ray diffraction on a Bragg-Brentano goniometer and also metallographically

investigated in an optical microscopy and scanning electron microscopy (SEM).

SEM allowed to determine basic microstructural parameters (volume portion of

pearlite and mean pearlite interlamellar spacing) directly. The choice of

samples for detailed metallographic investigation was made upon the results

obtained from X-ray diffraction.

X-Ray diffraction results

The

diffraction revealed a presence of residual stress in the steel, which is

expressed as an anisotropic shift of the diffraction lines [6]. The reason

could be the partial coherence of certain crystallographic planes of ferrite

and cementite in the pearlite arising from the displacive nature of the

eutectoid transformation. Furher on, an anisotropic dislocation-originated

broadening was observed (Fig. 1). The magnitude and anisotropy of the

integral breadth was evaluated according to

![]() . (2)

. (2)

Here l is the

radiation wavelength, binst instrumental broadening, bsize broadening due to a finite coherent

domain size (negligible) and edisl a root-mean-square microstrain in á100ñ direction, the anisotropy the

microstrain is described by parameter q [7]. The resulting values of q×e2disl are plotted versus e2disl in Figure 2, the q parameter

corresponds well with the expected presence of edge dislocations with Burgers

vector b = a/2×á111ñ. The magnitude of squared

dislocation microstrain differs by almost one order for different pearlitic

samples, so differs also the density of the dislocations.

|

Figure 1. Typical Williamson-Hall plot of the ferrite diffraction lines broadening. Broken line corresponds to instrumental broadening, cranky line connects the fitted theoretical values. |

Figure 2. Squared dislocation microstrain

and its anisotropy observed in diffraction line broadening. |

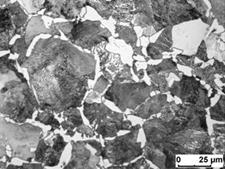

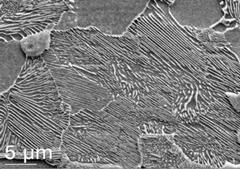

Microscopy

Figure 3

shows a microscopic view on the ferrito-pearlitic steel in three different

magnifications. Optical microscopy (Fig. 3a) can be exploited to determine

the pearlite volume fraction, since primary ferrite is displayed as light

areas. SEM allows to gain a mean interlamellar spacing in pearlite by means of

statistical methods [8]. The transmission electron microscopy (TEM) was

utilised to reveal the details of microstructure. As obvious in Figure 3c,

there are deformation fields present on the ferrite-cementite interface in

pearlite. The origin of these can be found in the presence of misfit dislocations

accommodating the difference in lattice spacing of the originally continuous

lattice planes (before the transformation). The dislocations are almost equally

spaced in a particular pearlitic colony and their mutual distance ranges from

20 to 30 nanometres. The primary ferrite grains as well as the inner volume of

the ferritic lamellas in pearlite are practically free of any dislocation.

(a) (b) (c)

Figure 3. Optical microscopy (a) and scanning electron microscopy (b) image of ferrito-pearlitic steel and a detailed transmission electron microscopy (c) image of ferrite and cementite lamellas in the pearlite

Results

The assumption was made that the misfit dislocations are responsible for the X-ray diffraction line broadening. Another assumption was made that the density of the dislocations is proportional to the density of the lamellas. Together, the dislocation squared magnitude of the dislocation line broadening (or the squared dislocation originated microstrain) should be proportional to the density of the lamellas (Fig. 4). Ultimate tensile stress (UTS) is roughly proportional to the weighted average of the pearlite and ferrite strength. The strength of the pearlite is inversely proportional to its interlamellar spacing (1), thus even UTS should be proportional to the density of lamellas, more-over to the squared dislocation microstrain (Fig. 5).

|

Figure 4. Correlation of lamellar density and dislocation originated squared microstrain. |

Figure 5. Correlation of ultimate tensile

stress and dislocation originated squared microstrain. |

References

1. R. F. Mehl, W. C. Hagel, Progress in Metal Physics 6,

(1956), pp. 74134

2. L. M. Brown & R. K. Ham, in Strengthening

Methods in Crystals, edited by A. Kelly & R. B. Necholson, London,

1971, p. 12

3. K. K. Ray, D.

Mondal, Acta Metall. Mater. 39, (1991), pp. 22012208

4. A. M. Elwazri, P.

Wanjara,

5. S.

Allain, O. Bouaziz, Mat. Sci.

6. D. Šimek, D. Rafaja, M. Motylenko, V. Klemm, G. Schreiber, A. Brethfeld, G. Lehmann, Steel Research Int. 79, (2008), pp. 800806

7. T.

Ungár,

8. J. Ohser & U. Lorz, in Freiberger Forschungshefte B 276, Technischer Verlag für Grundstoffindustrie, Leipzig, Stuttgart, 1994, p. 104

Acknowledgements.

The

authors also wish to thank to the German Scientific Council (DFG) for

supporting the project # RA 1050/10 in frame of the priority

programme SPP 1204.