MStruct course

Z. Matěj

Department

of Condensed Matter Physics, Faculty of Mathematics and Physics,

Charles University, Ke Karlovu 5, 121 16 Praha 2

matej@karlov.mff.cuni.cz

Outline

MStruct is a free computer program for Micro-Structure analysis from powder diffraction data. Purpose of this

course is a presentation of current possibilities of the MStruct program and a practical demonstration of the program for

solution of few problems concerning microstructure analysis by x-ray powder diffraction.

In the

first part a short introduction about the program is given. In the second part

a solution of few problems using the program is demonstrated:

1) residual stress evaluation in thin

TiO2 anatase films,

2) evaluation of crystallites size

distribution in anatase bulk nanopowders,

3) dislocation density determination in

an ECAPed Copper sample,

4) complex analysis of TiO2

anatase-rutile films on ITO glass substrates.

A short

insight into the proposed problems 1) – 4) is given in the text. Which

particular problems will be presented during the course depends on interest of

possible participants.

About the computer

program – introduction

MStruct is a free computer program for MicroStructure

analysis from powder diffraction data.

·

It

is practically a typical Rietveld program like many others famous programs: FullProf — Rodriguez-Carvajal; GSAS —Larson&VonDreele&Toby;

TOPAS — Kern, MAUD — Lutterotti; BRASS

— Birkenstock; Jana — Petříček; etc.

·

It

includes physically relevant models for peak broadening and shifts like PM2k — Leoni&Scardi and CMWP-fit — Ribárik&Ungár.

·

It

accounts for simple residual stress models, thin film absorption correction and

asymmetrical diffraction geometry like MAUD

— Lutterotti.

MStruct program utilizes free GPL projects for

Crystallography:

·

ObjCryst-FOX — Free Objects for Crystallography — Vincent Favre-Nicolin &

Radovan Černý

·

cctbx — Computational Crystallography Toolbox — Grosse-Kunstleve et al.

The program

is based on these GPL projects, extending them by routines for microstructure

effects modelling. MStruct is

available for free under the GPL license here: http://xray.cz/mstruct/.

|

|

|

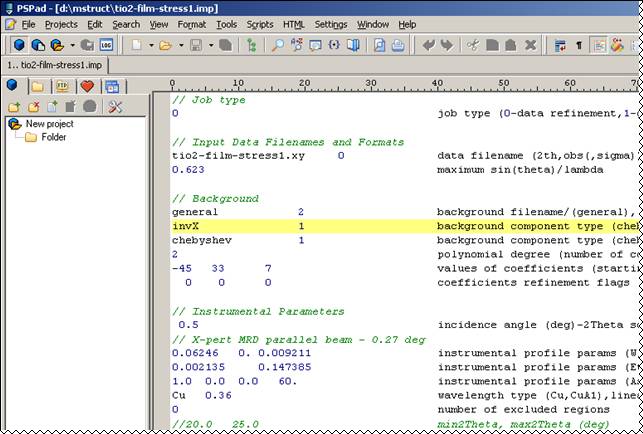

Figure 1. Editing of an input parameter file for MStruct in a PSPad freeware code editor |

Program

still has no GUI. Hence it relies on editing

input text files in an advanced text editor (Fig. 1) and on using some

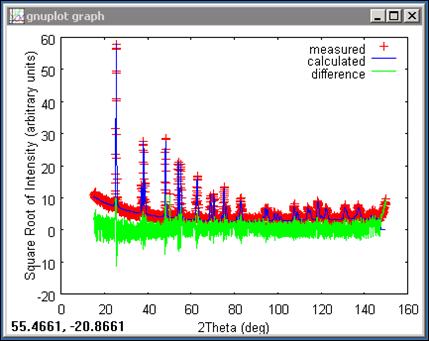

external plotting utility like gnuplot (Fig. 2) or commercial MATLAB.

|

|

|

Figure 2. Plotting MStruct

fitting results using free gnuplot program. |

Solution of

selected problems – practical examples

Tutorial no.

1: Residual stress evaluation in thin TiO2 anatase films

In this

example a powder pattern of TiO2 anatase thin film on a silicon

substrate is analysed. The x-ray pattern was measured as a wide range 2Theta

scan in the parallel beam (PB) geometry with low constant incidence angle Omega = 0.5°. Additional x-ray residual

stress measurements done using an Eulerian cradle and classical sin2Y method showed a presence of residual stress in the films. The aim of

this tutorial is an evaluation of a stress value in the film from the single

2Theta scan. A simple stress state is assumed in the film. It is described by

an absolute stress value and

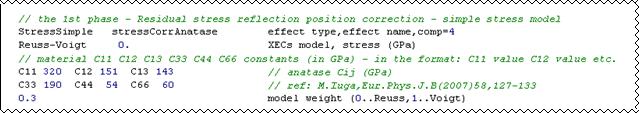

Reuss-Voigt grain interaction model weight. An appropriate section has

to be inserted into a MStruct input

parameter file to add an effect (Fig. 3).

|

|

|

Figure 3. Residual stress effect section for anatase

phase in an input parameters file. |

In the PB setup

used possible sample displacement is

small – less than few microns – and it has no effect on diffraction lines positions.

2Theta Zero value accuracy should also

be better than 0.01°. The strongest effect on diffraction lines positions has a

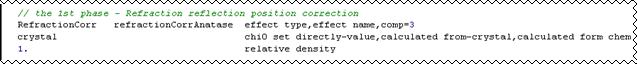

refraction effect of incidence x-rays

on the surface of the film. It causes 2Theta independent diffraction lines

shift which is equivalent to the Zero

shift error for a given material layer and it varies with the incidence angle Omega. The program can correct for this

effect (Fig. 4). The refinable parameter involved is a relative film density nr which is rather kept constant during refinement on

the value determined from reflectivity measurement of an angle of total

external reflection of x-rays acmeas and value calculated for the particular film

material accalc:

![]()

. (1)

. (1)

|

|

|

|

|

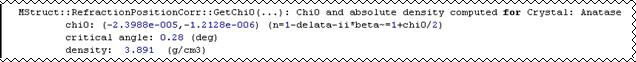

Figure 4. Top: Refraction correction section for

anatase phase in an input parameters file. Crystal structure is used to

account for the effect. |

Beside

described residual stress and refraction correction effect this example shows

also basic manipulation with line broadening effects, absorption effect and

arbitrary texture model. Detailed description can be found on the web: [1] http://xray.cz/mstruct/. Models involved are

described in detail in [2-3].

Tutorial no.

2: Evaluation of crystallites size distribution in anatase bulk nanopowders

In this

example a nanocrystalline TiO2 anatase bulk powder prepared by hydrolysis

of titanium isopropoxide in solution of hydrogen peroxide is analysed. The

sample was measured using a conventional Bragg-Brentano setup. The aim of

the example is an analysis of the crystallites size distribution accounting

properly for instrumental broadening and possible influence of crystal defects.

The analysis is a typical example of the whole powder pattern fitting/modelling

method established in [4].

Instrumental

resolution is taken from a measurement of LaB6 standard in the same

setup. Line broadening connected with a presence of crystal defects is

described by a phenomenological pseudo-Voigt function. Parameters involved are

a microdeformation e(%) and a

parameter determining Gaussian-Lorentzian character of a microdeformation part

of the diffraction profile. It is assumed in agreement with SEM images that

crystallites have spherical shapes. If no sophisticated technique is utilized produced

crystallites are usually polydisperse and hence it is appropriate to include

some description of grain size distribution into the model. Crystallites size

distribution of ceramic particles can usually be well described by the

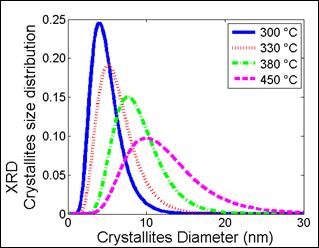

log-normal distribution. This is the first choice used in the example. Refined

size distributions for powders prepared from a same metal precursor and

calcinated at different temperatures are shown in Fig. 5. The second choice tested

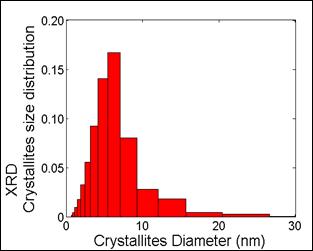

is a model [5] using a histogram representation of crystallites size

distribution. An example of the refined distribution is depicted in Fig. 6. (The histogram model

in MStruct is still under

development. However, some results can be tested.).

|

|

|

|

Figure 5. Crystallites size distribution of anatase nanopowders prepared from a same precursor and calcinated at different temperatures – model with log-normal distribution. |

Figure 6. Crystallites size distribution represented by histogram. |

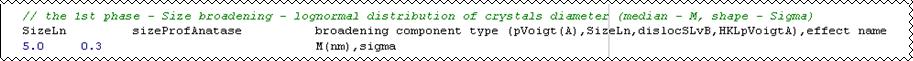

The

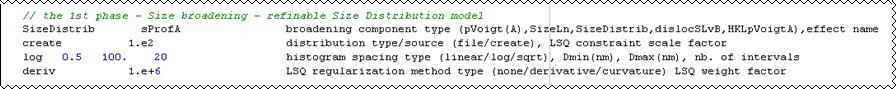

appropriate sections for the above models in a MStruct parameter file are depicted in Fig. 7.

|

|

|

|

|

Figure 7. Sections in input parameters files for a

size broadening models for anatase crystalline phase. |

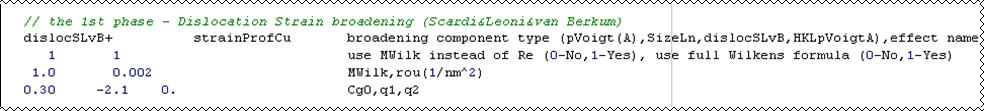

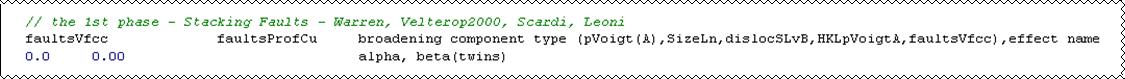

Tutorial no. 3: Dislocation density determination in an ECAPed Copper sample

In this

example a Copper sample treated by ECAP is analysed. The sample was measured in

the conventional Brag-Brentano setup with variable slits and PSD detector to

enhance data statistics of high angle reflections. In metal samples treated by

ECAP a high amount of defects is generated. Diffraction line broadening is

usually induced mainly by presence of dislocations, by small size of coherently

diffracting domains and by twin faults. The whole powder pattern modelling [4,

6] is a method which can estimate e.g. dislocation density values in such

materials. In this example a simple model describing [4, 6,7] these effects

will be used to determine coherently diffracting domains size, twinning probability,

edge-screw character of dislocations, dislocations density and Wilkens

characteristic parameter of their arrangement. An appropriate part describing

the effects is depicted in Fig. 8 and a typical pattern fit is shown in Fig. 9.

|

|

|

|

|

Figure

8. Sections in input parameters files for broadening

effects connected with defects in ECAP Copper. |

|

|

|

Figure 9. Powder pattern fit of an ECAPed (1 pass) Copper. |

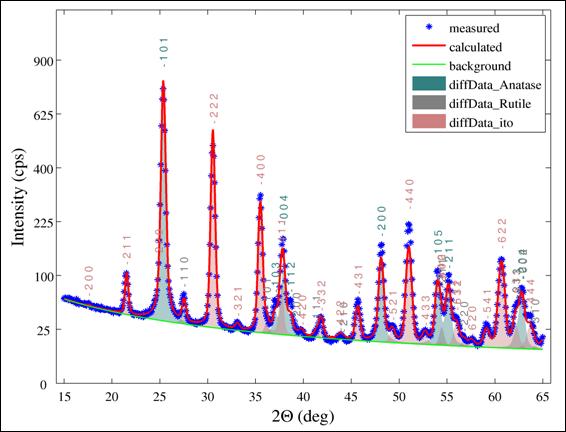

Tutorial no. 4: Complex analysis of TiO2 anatase-rutile films on ITO glass substrates

In this example a sol-gel TiO2 film on ITO glass substrate is studied. Film has thickness of about 200 nm and it was measured in parallel beam (PB) geometry with low incidence angle. Electron density of ITO is higher than el. density of TiO2. This helps to suppress ITO signal in PB setup. The film was calcinated at a relatively high temperature and it contains both anatase and rutile. The aim of this study is to roughly estimate crystallite size and relative anatase and rutile fractions. This tutorial employs refraction and stress corrections described in tutorial no. 1, peak broadening corrections used in tutorial no. 2 and if scale factors and absorption correction are further examined also some information about film thickness can be deduced from diffraction experiments.

|

|

|

Figure 10. Powder pattern fit of a TiO2 sol-gel film on an ITO glass substrate. |

References

1. Z. Matěj,

R. Kužel, MSTRUCT – program for MicroStructure analysis by powder

diffraction, http:/www.xray.cz/mstruct.

2. Z. Matěj, L. Nichtová, R. Kužel, Mater.

Struct. Chem., Biol., Phys. Technol., http://xray.cz/ms,

15 (1), (2008), 46.

3. Z. Matěj, R. Kužel, L. Nichtová, Powder Diffr.,

25 (2), (2010), in press [DOI:

10.1154/1.3392371].

4. P. Scardi, M. Leoni, Acta Crystallogr.,

A58,

(2002), 190.

5. M. Leoni, P. Scardi, J. Appl. Crystallogr., 37,

(2004), 629.

6. G. Ribárik, T. Ungár, J. Gubicza, J. Appl. Crystallogr., 34, (2001), 669.

7. L. Velterop, R. Delhez, Th. H. de Keijser,

E. J. Mittemeijer, D. Reefman, J. Appl.

Crystallogr., 33, (2000), 296.

Acknowledgements.

Grant

Agency of Charles University is kindly acknowledged for partially supporting

the program development trough the grant No. 258200, CSCA is

kindly acknowledged for providing space for the program presentation and

finally the authors kindly acknowledge the Academy of Sciences of the Czech

Republic for Grant No. KAN400720701 and the Ministry of Education of

the Czech Republic for the research program No. MSM0021620834.