X-ray scattering methods and new X-ray laboratory for coplanar and non‑coplanar reciprocal space mapping of solid and liquid surfaces at the Institute of Physics SAS

M. Jergel1,

K. Vegso1, P. Šiffalovič1, M. Weis1, Y. Halahovets1,

Š. Luby1,

1Institute

of Physics SAS, Dúbravská cesta 9, 845 11,

2Polymer

Institute SAS, Dúbravská cesta 9, 842 36,

Keywords: (GI)SAXS,

Abstract

The contribution gives an overview of

applications of X-ray scattering at the

Historical background

Utilization of X-ray scattering at the

Another impetus for development of X-ray

scattering methods at IP SAS dates back to the early 90-ties when novel

multilayer-based structures for X-UV optics and spintronics with the individual

layer thickness down to several nm started to be prepared at a newly

established Department of Multilayers. The research was focused on interface phenomena

which are crucial for multilayer structures. Here, specular X-ray reflectometry

and diffuse (non-specular) scattering at grazing incidence coming from randomly

rough interfaces provided a basic interface characterization in terms of the

interface width, interface roughness and its correlation properties. To perform

these studies, the X-ray instrumentation was extended by a high-resolution

diffractometer (Stoe) equipped with a non-dispersive double-crystal GaAs(400)

monochromator utilizing Fankuchen effect in the primary beam. Such a

monochromator provided a good compromise between the beam intensity and

spectral purity. Evaluation of the interface diffuse scattering was a

challenging task as the underlying theory was formulated in the same period. Effects

of deposition conditions and ion-beam treatment on the interface quality or multilayer

stability under thermal load induced by excimer laser irradiation or rapid

thermal annealing are typical examples of the multilayer studies of that period

(e.g. [2, 3]). They continued later with pioneering studies of coplanar and

non-coplanar X‑ray scattering effects on patterned multilayers

(multilayer gratings), utilizing also instrumentation at the collaborating Crystallographic

Laboratory CNRS in

Present X-ray research and instrumentation

In 2005, a Consortium for multidisciplinary

research of materials MULTIDISC was established from four institutes of SAS

including the

The new diffractometer and software stimulated new X-ray related research at IP SAS. Rietveld refinement (with TOPAS code), stress profiling and texture analyses of nanocrystalline alloys started at the Department of Metal Physics. Reflectivity studies (with LEPTOS evaluation code) and coplanar reciprocal space mapping in an extremely large dynamical range of 9 orders of magnitude became possible at the (renamed) Department of Multilayers and Nanostructures which allowed measurements of ultrashort-period multilayers with the period below 1 nm. The Department started collaboration with industrial and academic partners in advanced interface characterization of extreme multilayer optics giving a feedback for technology development. A combination of reflectometry with grazing-incidence small-angle X-ray scattering (GISAXS) measurements (BW4 beamline at DESY Hamburg) proved to be necessary to achieve the lateral resolution at nanometer level and to address special questions such as multilayer growth mechanism, clustering effects at ultrashort periods or interface scaling behaviour and morphology in terms of the power spectral density and its replication across the stack (e.g. [7]). X-ray studies of Néel coupling in spin valves exemplify application of the X-ray reflectometry to spintronic multilayers [8].

Since 2000 the research scope of the

Department of Multilayers and Nanostructures was extended by colloidal metallic

nanoparticles (mostly Ag and superparamagnetic Fe2O3) prepared

in collaboration with the Polymer Institute SAS. The nanoparticles are monocrystalline,

covered with a ~1 nm thick organic shell (surfactant) to prevent

agglomeration. The typical size is 6‑7 nm with a maximum dispersion

of 10%. The interest in the nanoparticles is driven by development of supported

and self-standing nanoparticle membranes for sensors and actuators or by novel

spintronic elements with nanoparticle arrays. Therefore the effort was focused

on studies of self-assembling phenomena where GISAXS with synchrotron radiation

proved to be a very convenient tool (ID10A at ESRF Grenoble and BW4 at DESY

From synchrotron to laboratory

GISAXS measurements of nanostructures such

as multilayers or nanoparticle assemblies have been confined to intense X-ray

sources so far as the scattering effects are weak. Because of well-known

reasons, synchrotron facilities cannot provide immediate or sufficiently

flexible access which aggravates systematic investigations. Therefore it was

decided to build a laboratory X-ray set-up with a microfocus source at the

Department of Multilayers and Nanostructures which will allow not only GISAXS (and

SAXS) but also non-coplanar grazing incidence diffraction (

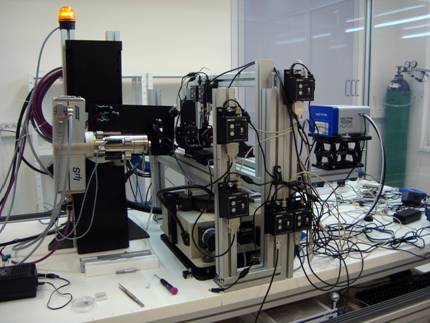

Figure 1. A total view of the set-up with microfocus source.

The X-rays (CuKa) are delivered by an air-cooled 30 W Incoatec Microfocus

Source (ImS) equipped with a 2D focusing Montel optics

(5 mrad divergence). The X-ray beam is reflected twice in L-shaped

monolith with optical surfaces coated with laterally graded multilayers (two

Göbel Mirrors). Suppression of the Kb component is more effective here than with a single-reflection 2D

focusing while the flux is still high (108 photon/s). The

optics housing is evacuated by a membrane pump. The nominal focal distance

(source to image) is 560 mm and the measured focal spot size is 270 mm (FWHM). The optics monolith is adjustable to maximize the useful

intensity as well as the exit aperture of the optics housing to block the

direct and singly reflected beams. Another aperture of optional size in front

of the sample defines the primary beam size. The sample is located in the focus

and the sample-detector distance controls the magnification of the scattering

pattern at

As the set-up is designated also for liquid

surfaces, the non-coplanar measurements are performed in the horizontal plane

while the coplanar ones are designed vertically. For them, the X-ray tube

housing with attached optics can be vertically translated and simultaneously rotated

around a horizontal axis to change the angle of incidence of X-rays on the same

spot. Independent translation and rotation are possible as well. The adjustments

of apertures, sample or beam-stop are facilitated by a visible semiconductor

laser beam which is set before to follow exactly the path of the primary X-ray

beam exiting the optics housing. The dynamic range is enhanced by a set of

rotating absorbers in the primary beam. For measurements of solid samples in

transmission or reflection geometries, a sample stage is used which can be

replaced by a container such as LB trough for liquid samples. To change the vertical

position, the detector is fixed on a lab-jack which is attached to a

horizontally rotating arm of a goniometer (Stoe) placed below a console

supporting the sample stage. A Soller slit of 5 mrad horizontal divergence

can be fixed on the detector arm to define the 2q angle for

The first SAXS and GISAXS measurements were

done on silver behenate which is used as a standard for SAXS and allows a

detector calibration. The horizontal beam position was adjusted with a small

MarCCD camera (delivered with the ImS source) which

has the pixel size smaller by one order of magnitude than

|

|

|

|

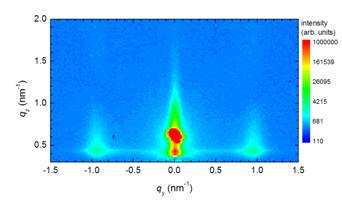

Figure 2a. GISAXS pattern of a Fe2O3 nanoparticle monolayer deposited on silicon measured on the set-up at IP SAS at an angle of incidence of 0.47°. |

Figure 2b. The qy cuts of the GISAXS patterns across the Yoneda peak calibrated on the same central peak intensity (full line - set‑up at IP SAS, dashed line - Nanostar). |

SAXS measurement of a colloidal solution of

~6 nm silver nanoparticles with 350 mm aperture showed the form factor with even the second oscillation which

proves a small dispersion of the nanoparticle size and high sensitivity of the

set-up. Diffraction from a polycrystalline copper foil gave well resolved rings

with grainy structure due to a small diffracting volume. The

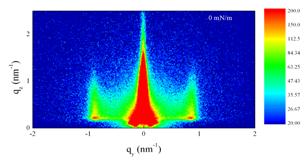

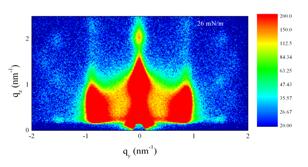

Time-resolved experiments were tested on a Langmuir film composed of silver nanoparticles used also for the SAXS test mentioned above. The film was created by spreading a colloidal solution onto the aqueous subphase and subsequently compressed with a constant velocity by movable barriers. The GISAXS was measured with 850 mm aperture at 0.2° angle of incidence (slightly above the critical angle of water) at the initial and final barrier positions in steady-state regime for 180 s as well as dynamically during the barrier movement (0.5 s exposition time). The surface pressure changed from 0 mN/m (discontinuous monolayer - gas phase) up to 26 mN/m (solid phase). From the very beginning, the film exhibited truncation rods at qy~0.8 nm-1 suggesting self-aggregation of the nanoparticles into locally ordered domains (Fig. 3a). The peaks became temporarily broader with increasing pressure above 5 mN/m which may be explained by boundary effects during the domain coalescence before a continuous monolayer was formed. This process was completed presumably at ~15 mN/m as at higher pressures, the truncation rods became modulated with the peaks located at different qz for different truncation rod orders (contrary to Yoneda peaks) suggesting a phase transition (Fig. 3b). In particular, the monolayer collapsed and a 3D ordered multilayer stack with a local order not only in the lateral but also in normal direction was established.

|

|

|

|

|

Figure 3a. GISAXS pattern of the Langmuir film of silver nanoparticles at zero surface pressure. |

Figure 3b. GISAXS pattern of the Langmuir film of silver nanoparticles at the surface pressure of 26 mN/m. |

|

Keeping the barriers at 26 mN/m surface pressure, the multilayer stack of silver nanoparticles was exposed to in-situ ozone treatment in a laboratory made UV reactor with a low pressure mercury lamp (hn = 4.9 eV, 6.7 eV) which was temporarily installed on the set-up. Such a treatment is an efficient way to remove the surfactant shell which is necessary for some applications of nanoparticle assemblies. A 10 minute exposure resulted in a disappearance of the truncation rods and loss of the ordered multilayer structure while after another 10 minute exposure, the GISAXS pattern was transformed into that of the aqueous subphase (the subphase was measured for reference still before the nanoparticles were applied). Obviously, the surfactant stripping resulted in a collapse of the Langmuir film and immersion of metallic nanoparticles which sank to the bottom of the trough. Comparing with our previous studies at synchrotron sources [xx], these results document principal differences between the nanoparticle behaviour on liquid and solid surfaces under similar treatments. They also confirm excellent performance of the new set-up which enables us laboratory experiments confined before solely to synchrotron sources.

Outlook

Future X-ray related research at IP SAS will continue in developments of complex structural characterization based on efficient combination of different X-ray techniques. The interest in new approaches to X-ray structural analysis is triggered by development of advanced nanostructures such as those for X-UV optics, spintronics, solar cells or sensors. They include nanostructures built on bottom-up (nanoparticles) and top-down (thin films) principles or combination of both of them (hybrid nanostructures). In addition to ex-situ experiments providing information on (meta)stable structure, time-resolved studies will be done to give insight into dynamics of the processes of interest. It is important that the Department of Multilayers and Nanostructures has its own technology base. It will be under permanent technical development financed by several new projects funded from Structural Funds of EU.

Acknowledgement

The construction of the new

multipurpose X-ray set-up was supported by Structural Funds of EU, project no.

ITMS 26240120011 of the Ministry of Education of the

References

1. M. Jergel, P. Mrafko, J. Non-Cryst. Solids, 85, (1986), 149.

2. M. Jergel, V. Holý, E. Majková, Š. Luby, R. Senderák, J. Appl. Cryst., 30, (1997), 642.

3. R. Senderák, M. Jergel, Š. Luby, E. Majková, V. Holý, G. Haindl, F. Hamelmann, U. Kleineberg, U.Heinzmann, J. Appl. Phys., 81, (1997), 2229.

4. M. Jergel, P. Mikulík, E. Majková, Š. Luby,

R. Senderák, E. Pinčík, M. Brunel, P. Hudek, I. Kostič, A. Konečníková , J.

Phys. D, 32, (1999), A220.

5. D.K. Agnihotri, V.E. Asadchikov, E. Bontempi,

D.K. Bowen, C.-H. Chang, P. Colombi, L.E. Depero, M. Farnworth, T. Fujimoto, A.

Gibaud, M. Jergel, M. Krumrey, T.A. Lafford, A. Lamperti, T. Ma, R.J. Matyi, M.

Meduna, S Milita, K.S akurai, L. Shabel'nikov, A. Ulyanenkov, A. Van der Lee,

C. Wiemer, J. Appl. Cryst., 41, (2008), 143.

6. R.J. Matyi, L.E. Depero, E. Bontempi, P. Colombi,

M. Jergel, M. Krumrey, T.A. Lafford, A. Lamperti, M. Meduna, A. Van der

Lee, C. Wiemer, Thin Sol. Films, 516, (2008), 7962.

7. P. Šiffalovič,

8. P. Šiffalovič, L. Chitu, Y. Halahovets, M. Jergel,

R. Senderák, E. Majková, Š. Luby, J. Appl. Phys., 101, (2007),

033538.

9. P. Šiffalovič, E. Majková, L. Chitu, M.

Jergel, Š. Luby, A. Šatka, S.V. Roth, Phys. Rev. B, 76,

(2007), 195432.

10. P. Šiffalovič,

11 P. Šiffalovič, L. Chitu, E. Majková, K. Vegso,

M. Jergel, Š. Luby, I. Capek, A. Šatka, G.A. Maier, J. Kečkeš, A. Timmann,

S.V. Roth, Langmuir, 26, (2010), 5451.