Study of the phase composition of Fe2O3

nanoparticles

Václav Valeš1, Jana Poltierová-Vejpravová1, Petr

Brázda2,

1Department of Condensed

Matter Physics, Faculty of Mathematics and Physics,

2Department of Inorganic

Chemistry, Faculty of Science,

Introduction

Important physical properties

of nanoparticles are determined mainly by their atomic structure, especially by

their phase composition and the presence of structure defects. X-ray

diffraction is a good tool for studying the structure of the nanoparticles, its

application for very small particles is however limited by very small intensity

of the scattered wave. For this reason special experimental setups, like e.g.

diffraction with small incidence angle, are used and many experiments have to

be done at synchrotrons. Standard methods of the measured data analysis based

on the description of the diffraction using instrumental functions and

functions of physical broadening of the lines fail in the case of very small

particles. An ab-initio calculation method (based on the Debye formula [1, 2])

has to be used instead.

In this work the Debye formula

is used for the description of the diffraction of iron oxide samples measured

at ANKA synchrotron in

Measured samples

The great interest in Fe2O3

nanoparticles is caused mainly by magnetic properties of these particles,

namely extremely high room temperature coercivity of epsilon phase of these

iron oxide nanoparticles. The samples were prepared by ex-situ annealing of

organic precursors and then measured at ANKA synchrotron in

Theoretical

description

Debye formula in Eq. (1),

which has been used for the x-ray data analysis describes the intensity

distribution of the samples consisting of the same randomly oriented particles,

knowing the positions of the atoms in one such a particle.

![]()

(1)

where the double sum goes over

all atoms in the particle, Q is the

length of the scattering vector, fi

is the atom form factor of the i-th

atom and rij is the

distance between i-th and j-th atom. The formula is valid for any

arrangement of atoms in any particle; no lattice is needed; only exact

positions of atoms in the particle are important. The only technical limit of

using of this equation is the number of terms in the double sum. For instance,

a particle of Fe2O3 of diameter of 13 nm contains about

105 atoms, which means that there are 1010 interatomic

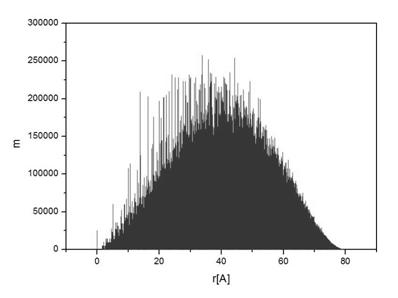

distances that have to be taken into account for every Q. For this reason, the distribution function of atomic pairs was

calculated and a histogram of all interatomic distances was created; an example

of such histogram is shown in Fig. 1 corresponding to a spherical particle with

the radius of 40 Å, the histogram has been constructed using the step

width of 0.01 Å.

|

|

|

|

Figure 1. Calculated

histogram of interatomic distances in a spherical Fe2O3

particle of radius of 40 Å. The histogram step is 0.01 Å. |

Figure 2. Calculation of

diffraction curves for different phases of Fe2O3. The

full line corresponds to the pure maghemite particle of radius of 50 Å; the dotted one to the pure ε-Fe2O3

particle of the same radius; and the dashed line represents the diffraction

from the particles of radius 50 Å, which consist of

the core (radius 40 Å) of maghemite and the shell of ε-Fe2O3. |

Since we introduced the histogram

of interatomic distances, we can rewrite the Eq. (1) using calculated data from

the histogram, i.e. we know the multiplicity of each of interval of distances.

The rewritten form of Debye formula in equation (2) enables us to perform

calculations for much larger samples. For the intensity we can write

![]()

(2)

where mi is the multiplicity factor for the i-th interval of distances. The

expression in Eq. (2) is valid only for one type of atoms in the particle,

which is not our case (because of different atom form factors). This fact

requires only some technical changes, which do not affect the fundamental

meaning of Eq. (2).

The phase transition from one

phase to the other is supposed to take place from the particle surface to its

center. For this reason the core-shell model of the particle (particle

consisting of two different phases) has been introduced to the Debye formula

program. In order to have a brief look in to the behavior of the simulated data

calculated by our model, diffraction curves for different phases were

calculated (Fig. 2). From this picture the difference between the maghemite and

ε phases of Fe2O3 can be seen as well as the effect

of the core-shell structure of these two phases, which causes some “mixture” of

the diffraction pattern of both phases.

Data analysis

Several samples from the

series described above were analysed by the Debye-formula approach using the

core-shell model, assuming that the interface of the two phases moves from the

surface to the center of the particle. The data from the Figs. 3 – 5 (samples A

– C) were fitted by hand and the results are summarized in Table 1; the errors

were estimated from this fit too. The background was approximated ad-hoc by a

polynomial of the third power. The broad peak around 13º is caused by the

amorphous SiO2 matrix and for our fitting is not important. The fits

describe the measured data well and the parameters of the core-shell model were

obtained. The sample D (Fig. 6) could not have been fitted because of a too

large size of the particles that made the simulation extremely time-consuming.

|

|

|

|

Figure 3. Sample A.

Measured data and fit of the sample annealed at the 900 ºC as the

highest temperature. |

Figure 4. Sample B.

Measured data and fit of the sample annealed at the 950 ºC as the

highest temperature. |

|

|

|

|

Figure 5. Sample C.

Measured data and fit of the sample annealed at the 1000 ºC as the

highest temperature. |

Figure 6. Sample D.

Measured data of the sample annealed at the 1100 ºC as the highest

temperature. |

Table

1.

Results obtained from the measured data fitting

|

Sample |

Total radius (Å) |

Maghemite (%) |

ε-Fe2O3 (%) |

|

A |

40 ± 4 |

34 ± 5 |

66 ± 5 |

|

B |

50 ± 5 |

26 ± 3 |

74 ± 3 |

|

C |

58 ± 5 |

0 ± 8 |

100 ± 8 |

From the fitting of the

measured data we obtained the total size of analyzed samples (A – C) and the

fraction of the maghemite and ε phase assuming the core-shell model with

maghemite as a core. It can be seen that the size of the particles increase

with increasing annealing temperature and that the fraction of maghemite

decreases and it completely vanishes at the temperature of 1000 ºC. This

corresponds to the assumption presented above. As for the sample D, which has

not been analysed, the hematite diffraction peaks appear.

Both he core-shell model of

the nanoparticles and the Debye formula are suitable tools for the analysis of

our samples. In the future we have to investigate, whether it is possible to

distinguish between the core and the shell, i.e., whether we can determine

which phase is in the core and which one is in the shell. A method, which would

enable us to analyze larger particles, has to be implemented as well.

References

1. A. Cervellino, C. Giannini, A. Guagliardi and D.

Zanchet, Eur. Phys. J. B 41 (2004), 485.

2. A. Cervellino, C. Giannini and A. Guagliardi, J. Appl. Cryst. 36 (2003), 1148.

3. Chang-Woo Lee, Sung-Soo Jung and Jai-Sung

Lee, Materials Letters 62 (2008), 561.

4. M. Gich, C. Frontera, A. Roig et al, Chemistry of Materials 18 (2006), 3889.

5. P. Brázda, D. Nižňanský,

J.-L. Rehspringer, J. Poltierová Vejpravová, J. Sol-Gel Sci. Technol., 51

(2009), 78-83.