Influence of protective gas on the phase composition of Mg-Ni-Fe-H based nanocomposite prepared by Spark synthesis

P. Roupcovį1, 2, O. Schneeweiss1

1Institute

of Physics of Material, Czech Academy of Science, v.v.i., Brno,

2Institute

of Materials Engineering,

roupcova@ipm.cz

The

metallic composites based on Mg(MgO) with 3d metals containing nanocrystalline

particles belong to the most expected candidates for hydrogen storage materials.

Their practical application, however, are connected with some difficulties due

to high temperature of hydrogen desorption and relatively slow kinetics of

absorption and desorption. This disadvantage could be overcome if these alloys

would be applied in a nanocrystalline form. The nanocrystalline alloys or

composites exhibit much faster kinetics of hydrogen absorption and desorption

and lower temperature of hydriding/dehydriding conventional crystalline

materials with the same composition [1-3]. The metallic hydride based on Mg-TM

and their nanocrystalline form is promising the improvement of properties. The

MgH2 contains approximately 7.6 wt. % hydrogen but its high

stability (H=-75kJ mol-1) and high pressure of 0.18 MPa at

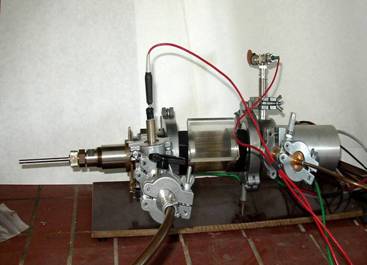

Spark erosion was performed in the two types of chamber. The first shows in the Fig. 1 do not provide the handling in protective atmosphere. This synthesis is a possible alternative among the methods for preparing a new Zr-Fe phase simultaneously yielding nanocrystalline particles. This method was used for the preparation of amorphous, nanocrystalline or crystalline powder materials. The conditions of erosion are characterised by high temperature (above 104 K) and pressure (~ 280 MPa) in a plasma channel, where a synthesis of the materials of electrodes with the surrounding occurs, and high cooling rate (~108 Ks-1) [7-8]. It allows to overcome the solubility limits reached by classic alloying treatments and to synthesize new materials. Moreover, there are some possibilities to modify its composition by varying the parameters of sparks (e.g., voltage or time) and/or chemical composition, temperature and density (pressure) of the gaseous or liquid dielectrics. The nanopowder was prepared by spark synthesis of electrodes of pure Mg (99.9 %) and Ni-Fe (99.9 %) in a hydrogen (5N) and hydrogen 10 % - argon 90 % atmosphere serving as dielectric [9-10]. The results obtained on samples handled in air were compared with the samples hold in envelopment with protective atmosphere.

Figure 1. The spark synthesis chamber works in floating gas.

The structure of the samples was checked by X-ray diffraction (XRD) using X’Pert diffractometer and CoKα radiation with qualitative analysis carried out by HighScore® software and the JCPDS PDF-4 database. For a quantitative analysis HighScore plus® with Rietveld structural models based on the ICSD database was applied. 57Fe Mössbauer spectra were collected by a standard transmission method at room temperature using a 57Co/Rh source. The calibration of the spectra is referred relative to α-Fe at room temperature. The computer processing of the spectra was done by the CONFIT package [11] yielding by intensities I of the components (atomic fraction of Fe atoms), their hyperfine fields Bhf, isomer shifts δ and quadrupole splittings Δ.

The TG/DTA results indicate presence of

hydrides and high adsorption capacity of moisture and air gases. We optimize handling of powder sample in various protected atmospheres due

its high sensitivity to oxidation and the trapping moisture and small molecule

of gases from air. The most significant problems were: purity of gases, size of

gasses molecules and absorption of X-rays. Although ability CO to protected the

nanopowder against oxidation was partial only, it was determined the most

effective gas. The XRD measurement observed FeNi3 and MgO phases in the all types of as-prepared samples handled in air and

in protected gasses expect the argon atmosphere. The Mössbauer spectra show in

figure 2 and 3 differences of amount of iron oxide phases. The sample handling

in air contains 18.7 atomic fraction (a. f.) of FeNi3 and

|

|

|

|

Figure 2. Powder handled in air. |

Figure 3. Powder handled in CO. |

References

1. W.

Liu, H. Wu, Y. Lei at all. J. Alloys Comp.,

261 (1997) 289.

2. T. Spassov, U. Köster, J. Alloys Comp., 287

(1999) 243.

3. L.E.A. Berlouis, E. Cambera, E. Hall-Barientoss at

all., J. Mater. Res., 16 (2001) 45.

4. K.H.J. Bushow, P.C.P. Bouten, A.R.

Miedema, Rep. Prog. Phys., 45 (1982) 937.

5. J. Huot, H. Hayakawa, E.Akiba, J. Alloys Comp., 248 (1997) 164.

6. J.J. Didissheim, P.Zolliker, K.

Yvon at all. Inorg. Chem., 23 (1984) 1953.

7. A. Zaluska, L. Zaluski, J. O. Strom-Olsen, Appl. Phys. A., 72 (2001) 157.

8. L. Chen, F. Wu, M. Tong, B.R .Long, Z.Q. Shang, H.

Liu, W.S. Sun, K. Yang, L.B. Wang, Y.Y. Li, J.

Alloys Comp., 293 (1999) 508.

9. J.L. Walter, Powder Metall., 31 (1988) 267.

10. A.E. Berkowitz, J.L.

Walter, Mater. Sci.

11. T. ˇįk, in Mössbauer Spectroscopy in

Materials Science,

edited by M. Miglierini and D. Petridis (

Acknowledgements.

This work was supported by the Czech

Ministry of Education, Youth and Sports (1M6198959201),