Electron

diffraction – SAED, CBED, PED

M. Klementovį

Institute

of Inorganic Chemistry of the ASCR, v.v.i., 250 68 Husinec-Ųe˛ 1001, Czech

Republic

klemari@iic.cas.cz

Keywords: electron diffraction, SAED, CBED,

PED

Introduction

Due to a much

stronger interaction of electrons with matter compared to X-rays, electron

diffraction has non-negligible advantages over X-ray diffraction. Nano-objects

that are too small for conventional X-ray diffraction experiment and would have

to be taken to a synchrotron can be studied in the laboratory by electron

diffraction. Electron diffraction is readily available on any TEM (transmission

electron microscope) where it can be further combined with other complementary

techniques such as imaging and/or spectroscopy. Moreover, electrons are

scattered by light atoms relatively more strongly, and electron diffraction

patterns can show reflections corresponding to a resolution beyond that

available with X-rays. However, the much stronger interaction of electrons with

matter as well as very small diffraction angles also cause strong dynamical

diffraction effects, such as multiple diffraction, which hinder structural

interpretation of electron diffraction patterns.

SAED –

Selected-area electron diffraction

In SAED [1],

a parallel beam (plane wave travelling in one direction) interacts with sample.

An aperture is used to define the area from which the diffraction pattern is to

be recorded from a thin sample. This aperture is typically located in the first

image plane below the sample. Typical size of an area studied by SAED is a few

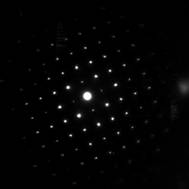

hundred of nanometers. SAED diffraction patterns are either simple spot patterns

corresponding to single-crystal diffraction or ring patterns corresponding to

powder diffraction from multiple crystals with a variable orientation (Fig. 1).

SAED is

commonly used for phase identification, determination of structural intergrowth,

determination of growth directions etc. Lattice parameters from SAED

have accuracy of approx. 5%, and due to multiple diffraction

kinematically forbidden reflections are often present.

CBED –

Convergent-beam electron diffraction

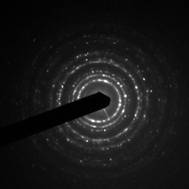

In CBED [2],

the incident electron beam is a cone of incident rays impinging on sample over

a range of angles. As a result, a diffraction spot will appear as a disc in the

back focal plane (Fig. 2). Such disc contains information from higher-order

Laue zones (HOLZ). Using convergent beam overcomes the limitation of SAED for

analyzing only areas of approx. 500 nm in size. However, with CBED, the areas

studied are limited by the beam size and the beam interaction volume (approx.

10 nm).

CBED yields

information about specimen thickness, unit-cell parameters (accuracy of approx.

0.01%), crystal system and 3D crystal symmetry (point group and space group).

PED –

Precession electron diffraction

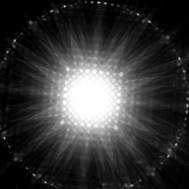

PED is

equivalent to the Buerger precession technique [3] used in X-ray diffraction

where the specimen as well as the photographic plate circumscribe the surface

of a cone (the precession movement) with

respect to the X-ray incident beam in order to record an undistorted image of

reciprocal space. In the electron precession technique, it is the electron beam

that is tilted and moved along the cone surface having a common axis with the

TEM optical axis and with the studied zone axis of the specimen (Fig. 3).

PED was

first proposed by Vincent & Midgley [4]. The data show reduced dynamical

effects because there are far fewer simultaneously excited reflections in the

off-zone condition. In addition, the precession integrates the diffraction

intensities through the Bragg condition, which provides data sets less subject

to minor sample tilt, and makes the interpretations of pattern symmetry more

reliable.

|

a) |

b) |

|

Figure 1. SAED: a) spot pattern – SnO2

along [001], b) ring pattern – RuO2. |

|

|

a) |

b) |

|

Figure 2. CBED: a) including HOLZ – SnO2

along [001], b) simulation of centre disc of CBED by JEMS – SnO2 along

[100] [5]. |

|

|

a) |

b) |

|

Figure 3. Electron diffraction of mayenite:

a) precession off, b) precession on [6]. |

|

References

2. J.B.

Poole, Philiops Tech. Runsch., 9,

33.

1. W. Kossel,

G. Möllenstadt, Ann. der Phys., 36, (1939), 133.

3. M.J. Buerger, The precession method in X-ray crystallography. John Wiley and Sons, Inc. New York. 1964.

4. R. Vincent, P.A. Midgley, Ultramicroscopy, 53, (1994), 271.

5. P. Stadelmann (2009). JEMS—ems java

version, CIME-EPFL,CH-1015 Lausanne, Pierre.Stadelmann@epfl.ch.

6. http://www.nanomegas.com/liveNew.php - downloaded on June 1, 2009.

Acknowledgements.

Financial support through project AV0Z40320502 is gratefully acknowledged.