X-ray high resolution imaging CCD camera based on a thin scintillator screen

J. Touš1, K. Blažek1, L. Pína2, B. Sopko3

1Crytur

spol. s r.o., Palackého 175, Turnov CZ-511 01,

2Faculty of Nuclear Sciences and Physical Engineering,

3Faculty

of Mechanical Engineering,

Keywords: high resolution imaging, YAG:Ce, LuAG:Ce, single-crystal imaging screen, micro-radiography, synchrotron beam inspection

Abstract

A high-resolution CCD X-ray camera based on YAG:Ce or LuAG:Ce thin scintillators is presented. The high resolution in low energy X-ray radiation is proved on several objects. The achieved spatial resolution of the images is better than 1 micron. The objects used for imaging are grids and small animals with parts of several microns in dimension. The high-resolution imaging system can be used for different types of ionizing radiation (X-Ray, electron, UV, and VUV) for non-destructive micro-radiography and synchrotron beam inspection.

Introduction

The spatial resolution of an X-ray and ionizing radiation imaging system is one of its most important parameters in X-ray non-destructive micro-radiography and radiation beam inspection. The imaging systems are mostly based on two-dimensional position-sensitive detectors (PSD). There are many different types of PSD detectors with each having its advantages and disadvantages [1]. X-ray micro-radiography is an X-ray imaging method well known from a number of medical and biological applications related to the imaging of very small objects. The sample is irradiated with X-rays with energies sufficient for penetrating the object and being detected with a fine resolution X-ray position-sensitive detector. Different parts of the sample usually have different integral (different integral absorption lengths can be caused by different materials or different thicknesses) attenuation lengths for X-rays of given energy and therefore the intensity of detected X-rays depends on the properties of the sample materials.

The presented high resolution imaging system is a combination of a high sensitive digital CCD camera and an optical system with a thin scintillator imaging screen. The screen is the YAG:Ce (Y3Al5O12) or LuAG:Ce (Lu3Al5O12) inorganic scintillator. High quality industrial YAG:Ce and LuAG:Ce single crystals were prepared by the Czochralski method [2] at Crytur. These materials have the advantages in the mechanical and chemical stability and the non-hygroscopicity. The imaging scintillator screen is optically transparent. The emission wavelength of YAG:Ce and LuAG:Ce is 550 nm and 535 nm, respectively.

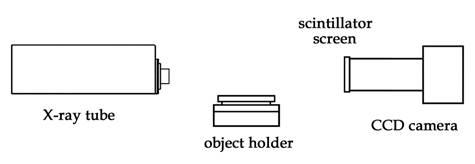

Figure 1. Experimental setup.

Experiments

The scheme of the experimental setup is

shown in Figure 1. The scintillator was placed in the focused object plane

of the optics. In the experiments, the scintillators have the shape of a round

plate with diameter of

Results and discusion

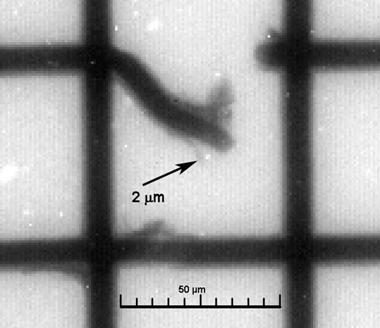

Figure 2 presents an image of a golden grid

made of wires which have a size of about 10 microns. The image was taken by using the LuAG:Ce

20 µm screen. The effective pixel size of the CCD camera used was

0.74 µm. The X-ray microfocus source was operated at 40 kV/2mA. The

image acquisition time was 5 s and the averaging was performed with

samples of 25 images.

Figure 2. Radiographie of a gold-grid taken by using LuAG:Ce

thin screen.

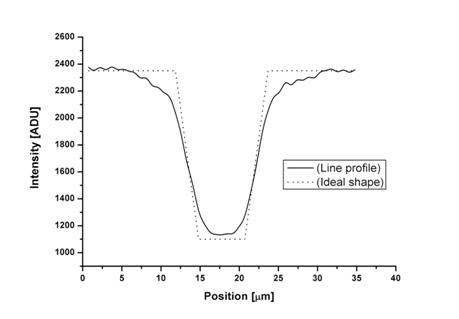

It shows that the resolution of the imaging system is in the order of micrometers. The line profile of one grid wire is shown in Figure 3. The profile is compared with the geometric profile of the grid wire, which has trapezoidal shape with a base of 10.7 µm and top 6.8 µm wide (measured in an SEM image of the grid).

Figure 3. Line profileof the grid wire.

The optical properties of YAG:Ce and

LuAG:Ce materials allow to

achieve the very high spatial resolution of 1 micrometer, which is about ten

times higher than standard x-ray imaging CCD cameras (standard X-ray imaging

CCD cameras have pixel size from 10 to 24 mm, also due to charge capacity and

use mainly non-transparent phosphors). The spatial resolution of the screen depends

on screen thickness, photon energy and the depth of absorption of the photon. An

optical system using a magnifying lens was used to transfer

the scintillator screen image to the CCD image area surface.

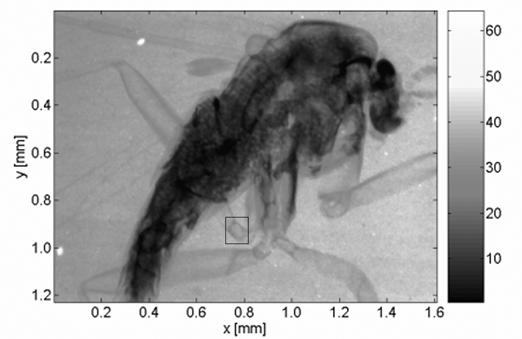

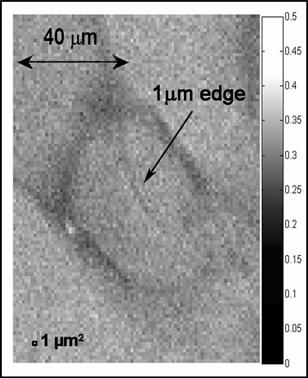

Several biological samples were studied in the next experiments. Here only Drosophila is presented. The image is shown in Figure 4 with the grayscales indicating the transparency of the sample.

Figure 4. Microradiography of the body of

Drosophila melanogaster.

The images were taken by the CCD camera in the same setup as the images of the grid, using a YAG:Ce 20 µm screen and a magnifying lenses. The acquisition time was set to 20 s.

The zoom image showing selected details of the fly’s leg in Figure 5 demonstrates that a resolution of about several µm is achievable by the used imaging system. The effective pixel size of the system is about 0,65 µm.

Figure 6. Microradiography of Drosophila

melanogaster – a detail of the leg.

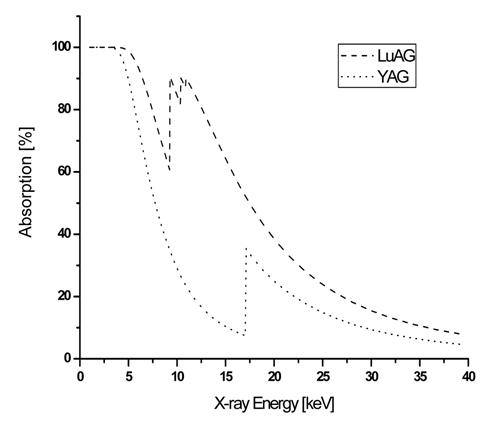

Figure 7. Absorption of X-ray radiation in

20 microns thick layer of YAG and LuAG [3].

The intensity of the light generated by LuAG:Ce is about 1,51 times the value of YAG:Ce. The light was detected by the CCD and averaged in a squared ROI of 200 x 200 pixels. The LuAG:Ce single crystal is more dense compared to YAG:Ce (density: 6.73 to 4.57 g.cm-3) and the X-rays are absorbed stronger by LuAG (1.7 times more of X-ray radiation (photons) is absorbed in the range between 1 and 40 keV), as can be seen in Figure 7. Attenuation coefficients are taken from [3].

Conclusion

In the experimental setup presented, a high resolution imaging system based on CCD camera with lenses and precisely manufactured YAG:Ce and LuAG:Ce single crystal screens was used for X-ray micro-radiography.

The mean absorption depth of X-ray radiation in the scintillator depends on photon energy and the material. The YAG:Ce and LuAG:Ce screens are optically transparent so the image of interaction points is easily transferred to the CCD. However, the advantage of the material transparency decreases with the thickness of the imaging plate. If the scintillator is thinner, the mean absorption depth is lower and the created image is sharper due to less blurring of the image due to less lateral spread of the scintillation photons. Hence, the thinner the imaging plate is, the better is the resolution achieved in the image. On the other hand, the detection efficiency decreases with scintillator thickness.

The experiments proved that the YAG:Ce and LuAG:Ce screens are suitable for imaging with high spatial resolution. The submicrometer spatial resolution using synchrotron radiation has been already achieved [4]. The resolution of the presented imaging system is about one micrometer.

The LuAG:Ce screen has higher conversion efficiency than the YAG:Ce screen, so that the signal to noise ratio of the image is better.

References

1. van Eijk, Carel W. E., Inorganic

scintillators in medical imaging; Phys. Med. Biol. 47 (2002) R85-R106.

2. Brandle, C.D., Czochralski growth of

oxides, J. Crystal Growth 264 (2004)

3. X-Ray Form Factor, Attenuation, And

Scattering Tables, http://physics.nist.gov/.

4. Koch, A., X-ray imaging with submicrometer

resolution employing transparent luminescent screens, J.Opt.Soc.Am. A/Vol. 15,

No. 7/July 1998,

Acknowledgements

This work was supported by the grant

of the Ministry of industry and trade of the