Real structure depth profile of shot-peened surface of a corrosion-resistant steel

J. Drahokoupil1,2, N. Ganev1, M. Čerňanský2, M.

Stranyánek2,3, R. Čtvrtlík2,3

1 Faculty of Nuclear Sciences and Physical Engineering, Czech Technical University, Trojanova 13,120 00 Praha 2, Czech Republic.

2 Institute of Physics of the ASCR, v.v.i., Na Slovance 2, 182 21 Praha 8, Czech Republic

3 Joint Laboratory of Optics of Palacky University and Institute of Physics of the ASCR, v.v.i., 17. listopadu 50, 772 07 Olomouc, Czech Republic.

jandrahokoupil@seznam.cz

The main goal of this paper is to

characterize surface layers of corrosion-resistant steel affected by shot peening. Several experimental methods were used for

investigation of samples prepared by using two different levels of shot peening intensity.

X-ray diffraction was applied as a main technique for particle size,

microscopic and macroscopic residual stress determination. Combination of X-ray

diffraction with electrolytic

polishing enables to study the depth profile of aforesaid quantities. Nanoindentation and optical microscopy were also applied on

polished cross sections of the samples. It was observed that more intensively

shot-peened sample differs from the lesser

intensively one mainly in the wide of affected zone, which was ca. 0.4 mm and

ca. 0.2 mm respectively. Significant correlation was observed between the depth

profiles of macroscopic residual stress and particle size. No change in phase

content due to surface treating was found.

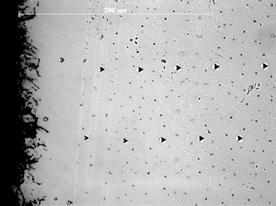

The

obtained depth profiles of residual stresses are plotted in Fig. 1. The lesser

intensively shot-peened sample is marked as C11, the more intensively one as C13. A micrograph of the cross section

prepared from the sample C11 is shown

in Fig.2. Black triangles are residual nanoindentation impressions.

Fig. 2. Sample C11, zoom 50x.

Acknowledgement

The research was supported by the Project № 106/07/0805 of the Czech Science Foundation and by COST 532 action, project No. OC095 and COST 533 action, project No. OC097 of the Ministry of Education, Youth and Sport of the Czech Republic, and by Project MSM 6840770021 of the Ministry of Education, Youth and Sport of the Czech Republic.