X-ray Diffraction Analysis of Heat-Affected Particles of Tool Steel Ch3F12 Powder

R. Cízlová, M. Kusý

Slovak University of Technology, Faculty of Materials

Science and Technology, Institute of Materials Science, J. Bottu 23, 917 24

Trnava, Slovak Republic

romca82@post.sk, martin.kusy@stuba.sk

The investigated tool steel Ch3F12 belongs to the group of tool steels of ledeburte type. This steel is produced by powder metallurgy e.g. rapid solidification (gas atomisation) usually. Powder metallurgy belongs to effective processes of steel production. High quality of products (homogeneous structure, liquation is suppressed) is obtained by PM. At the same time good mechanical, technological and utility properties, which are required from the tool materials, are reached. Materials do not solidify according to equilibrium phase diagram during rapid solidification. It results in final microstructure of elements composed of various metastable phases depending on the size of undercooling and on condition of heat dissipation through the surface of solidifying droplet. As-cast rapidly solidified (RS) particles of Ch3F12 alloy typically consist of metastable austenite and other metastable phases [1]. One of the effects of the rapid solidification is austenite supersaturation with carbon and alloying elements. After rapid solidification and following thermal exposition e.g. (upon the process of compaction or heat treatment) the phase transformation of this austenite occurs and causes a change of materials properties. Therefore, the aim of this analysis was to determine the phase quantity using X-ray diffraction analysis. Analysis revealed the change of the quantity of metastable austenite depending on the temperature of heat-treatment of RS powder particles in comparison with the phase constitution in as-cast state. Furthermore, results show temperature dependence of cell parameters, size of crystallites and crystal strain of RS powder particles.

The experiment comprised of annealing the experimental materials at following temperature 300, 400, 500, 540, 560, 580, 600, 650 and 700 °C. The second step was quantitative X-ray diffraction phase analysis, which was performed using program MAUD (Microstructural Analysis Using Diffraction) utilizing the Rietveld method [2]. The change of unit cell parameters, size of crystallites and crystal strain of RS powder particles were evaluated in dependence on the annealing temperature. Mechanical properties of powder particles were revealed with the microhardness measurements.

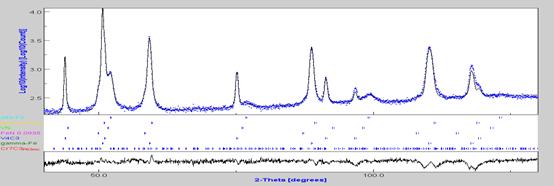

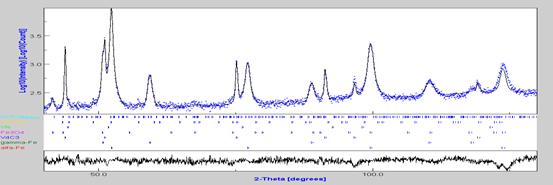

Analysis showed that thermal exposition of RS particles of Ch3F12 alloy trigger change of the austenite rich in carbon to the ferrite. Simultaneously, the carbide phases are precipitated. This process appears either upon the cooling from the temperature of thermal exposition or at thermal exposition temperature. The transformation from austenite to ferrite was observed to start at 400 °C and finish at 560 °C. Between 400 °C and 500 °C the carbide phases was precipitated in the form of the fine precipitates. Over 500 °C the quantity of Cr7C3 becomes highest contributing to the maximum microhardness. Above 540 °C the phases Cr7C3 and Cr23C6 coarsen, therefore the microhardnes decreased. This behavior is also connected together with the fact that from 560 °C the sample does not contain longer precipitate hardened austenite [3]. Analysis further showed that transformation from austenite to ferrite is connected with the change of lattice parameters, crystallites and microstrain. Quantities of phases in dependence on the annealing temperature are displayed in Fig.1. The Fig. 2 and 3 shows difference in diffraction patterns and phase quantities. Data in Fig. 2 represents the powder particles in as - cast state where the powder contains 68 vol.% of austenite, 23 vol.% V4C3, 6 vol.% ferrite and 3 vol.% of minor phases. Diffraction pattern in fig. 3 were taken at room temperature from the sample annealed at 540 °C, which contained 10 vol.% austenite, 22 vol.% V4C3, 62 vol.% ferrite, 4 vol.% Cr7C3 and 1,5 % Cr23C6, 0,5 vol.% VN.

Fig. 1 The dependence of phase quantity on the annealing temperature

Fig. 2 X-ray diffraction pattern of the Ch3F12 powder in as-cast state

Fig. 3 X-ray diffraction pattern of the Ch3F12 powder annealed at 540 °C

The presence of phase transformation from austenite to ferrite was showed to take place during thermal exposition. The kinetics of phase transformation – the austenite changed into the ferrite and precipitates of carbide phases were evaluated using X-ray diffraction analysis. In terms of mechanical properties characterized using microhardness the Ch3F12 tool steel is thermally stabile from 540 °C to 600 °C [3]. The microhardness decreases sharply above 600 °C. It is due to coarsening of the carbide precipitates and ferrite.

We acknowledge financial support of

Slovak Grant Agency VEGA provided to project VEGA 1/4107/07 and VEGA 1/3190/06.

1. M. Kusý, Dissertation thesis, MtF STU (2001)

2. R. Černý, P. Fejdi, V. Kavečanský,

Jesenná Rietveldovská škola, Liptovský Hrádok

(2002)

3. P.

Grgac, R. Moravcik, M. Kusy, I. Toth, in Materials Science and

Engineering A 375

- 375, (2004), pp. 581 - 584