Application of X-ray Powder Microdiffraction in Non-destructive Microanalysis of Colour Layers and Microtraces

V. Šímová Grunwaldová1, M. Kotrlý2,

P. Bezdička1,

1Institute

of Inorganic Chemistry ASCR, 250 68 Rez,

2Institute

of Criminalistics Prague, Strojnicka 27, PO box 62/KUP, 170 82

Keywords: micro-XRPD, mineral pigments, paintings, microtome slice

Introduction

Analysis of pigment phases is one of standard operations in many material fields as well as in the forensic science sphere. It is required for expert examination of a whole range of evidence (car paints, abrasion of lacquer systems of tools and instruments, fragments of interior and exterior paints and plaster coats, painting pigments etc. – exhaustive listing could be very lengthy). The existing analytical practice, requiring the sample to be divided for individual instrumental methods, was beginning to prove unsatisfactory because in a number of cases stated above it is necessary to study every single layer separately and the results of stratigraphy studies can contribute to expression or dismissal of the generic match possibility in comparisons. Furthermore, considering the sample inhomogenity, it was often possible to arrive at misleading information.

Methodology

Therefore, the

The role of powder microdiffraction, which in most cases allows direct exact phases identification, is important in this complex methodology. Measurements were made on an X’PertPRo diffractometer made by a Dutch company PANalytical. It is a combination of a common X-ray tube, a capillary, which focuses the X-ray beam into the diameter of 0.1 mm, and a position-sensitive detector. The set enables phase analysis from the area of hundreds of square micrometers in hours.

It was established that successful measurement of raw samples is possible, e.g. artwork fragments, layers applied on mats of various shapes (glass slide, thin wire etc.) or powders. At the same time it is possible to measure samples fixed in the filler and polished in their cross section, or microtome sections from these filled samples. Only such polished section allows measurement of each layer in technological sequence. With raw fragments it is sometimes very difficult to find the measuring area, so that in the area of low angles there is no shading caused by surface unevenness. In the case of polished sections, problematic are fillers most commonly on the basis of polyester resin, which causes diffraction lines widening and worsens background noise. The same effect applies to generally present organic binders in samples of colour layers in paintings or polychromy. For sample adjustment, a thin silicone non-diffractive mat proved useful. It is made of monocrystalline silicone drawn in the direction (100). The ingot was then cut into slices of 0.3 mm in such a way, that the cut was conducted in the angle of 7 degrees to the plane perpendicular to growth direction (100). Thus, the diffraction phenomenon does not occur in the mat material. These mats can be used universally and apart from XRD analysis, also transmission FTIR and SEM/EDS can be performed from one cut adjustment. With SEM/EDS it is in some cases necessary to lower the operating voltage with ultrathin sections).

Perfectly polished section in clear filler, which does not demonstrate UV luminescence, is optimal for the purposes of optical microscopy, SEM/EDS and colorimetry. Microscopic methods are realized first; therefore the polishing step cannot be left out. However, for the purposes of powder X-ray microdiffraction it is necessary to roughen the polished section surface or cut it – to get rid of the filler traces, which contaminate it during polishing. For IR microspectrometry both the filler and rough surface bring complications – therefore the best surface treatment is microtome cutting or the preparation of a microtome section for transmission measuring.

Figure 1. Microphotograph of the painting sample section with indicated measuring points.

Measuring geometry of powder X-ray microdiffraction can be changed for samples of various heights. It is necessary to eliminate as much as possible the contribution of the filler into the whole analytical signal of polished and microtome sections measurement. Although this contribution does not disable the measurement itself, the interpretation of the consequent diffractogram is influenced in the area of low angles in case of all types of fillers. It is necessary to take into account that the detection limit of phase determination with light elements is ca. 5 mass %.

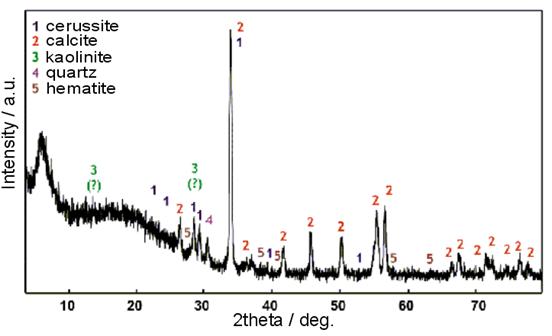

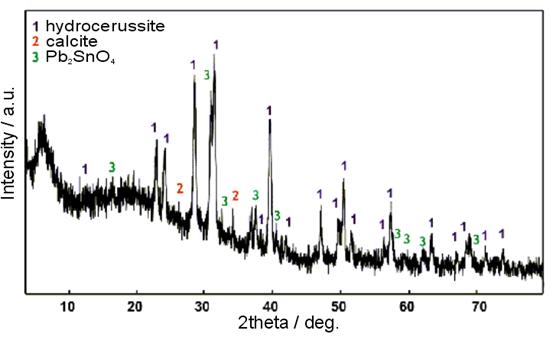

Fig. 1 illustrates the application on a real sample microtome section of a painting in Bylapox resin. The sample is composed of three basic layers – the underlayer, under-painting and painting. Results of the analysis are presented in fig. 2 and 3.

Figure 2. Diffractogram of the sample section brown underlayer in point 2.

Figure 3. Diffractogram of the sample section yellow colour layer in point 3.

Acknowledgements.

The authors acknowledge the

financial support from the