Keywords

nanoindentation,

NanoTestTM, thin films

Abstract

The depth

sensing indentation technique is increasingly being used to probe the mechanical

properties of materials. There is referenced the Oliver-Pharr method for

analyzing indentation load-depth data in this paper. We determined the hardness

and the elastic modulus of thin films prepared by magnetron sputtering

experimentally using The NanoTestTM instrument. Load was applied by

force in horizontal direction. This untraditional arrangement of the experiment

allows just original construction of the NanoTest platform.

1. Introduction

The chemical

resistant and the high hardness of diamond-like carbon films allow some tribology

applications. Amorphous carbon films commonly have resistance against abrasive

and adhesive wear and the low coefficient of friction. Special thin films can

enlarge the operating lifetime of product. Research and development of new and

superior procedures of the surface treatment of material can bring significant

increase of product manufacture qualities moreover savings of the critical

materials. An Investigation of mechanical properties allows produce layers and

coatings with exactly defined features.

The Instrumented

indentation offers advances in sensitivity and data acquisition. These benefits

are significant in materials science particularly regarding fundamental

mechanisms of mechanical behaviour at micrometer and even sub-micrometer length

scales.

We examined a-C

a a-C:Si films from amorphous carbon on Si substrates. The thin films produced

by the DC magnetron sputtering from carbon target in chemically poor argon in

vacuum chamber (with the stuck Si little sheet in the second case) of

commercial vacuum machinery the Leybold Z 550M. A description of the

sputtering equipment and deposition parameters were published previously e.g. [1].

Thickness of the layers was measured by the ALPHA STEP 500 apparatus. Sample a-C

no. 516: 1,62 mm, sample a-C:Si no. 846-1: 2,29 mm. We measured certain silicon films as well. Its

indentation behaviour is more complicated by cracking and pressure-induced

phase transformation [2, 3].

2. Instrumented

indentation

Depth sensing indentation

(DSI) also known as instrumented indentation or nanoindentation [4] is

increasing being used to evaluate the mechanical properties of materials having

very fine microstructure such as thin films. In contrast to traditional

hardness testers instrumented indentation systems allow the application of a

specified force or displacement course. The force and the displacement are

controlled and measured simultaneously and continuously over a complete loading

cycle. Moreover the extremely small force and displacement resolutions often <

1 mm are possible.

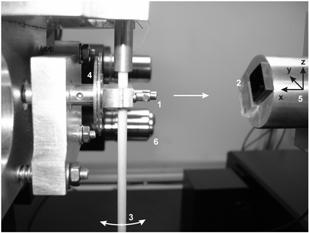

Fig.

1.

Indentation part of the NanoTestTM

system: 1 – indenter, 2 – samples, 3 – pendulum, 4 – capacitor plates, 5 –

sample holder with x-y-z nano-feedings, 6 – microscope.

Many

instrumented indentation systems can be found on the market. We used commercial

the NanoTestTM NT600 platform. The instrument makes use of its

unique pendulum design (Fig. 1). The pendulum pivoted on

frictionless bearings combines vibrating stability with the ability to carry out

a wide range of measurements. To measure nano-mechanical properties a very

small calibrated diamond indenter is brought into contact with the sample

surface and a load is applied by means of a coil and magnet located at the top

of the pendulum. The resultant displacement of the probe into the surface is

monitored with a sensitive capacitive transducer in real time as a function

of load [5].

After reaching

a predefined maximum value the load is reduced and the penetration depth

decreases due to the elastic recovery of the deformed material. The depth and

load are monitored continuously which allows both hardness and elastic modulus

to be determined.

3. Analysis of

the nanoindentation data

Different

analytical approaches were developed to extract mechanical properties,

generally the hardness H and the

elastic modulus E. The Oliver-Pharr

method introduced in 1992 [6] and refined in 2004 [7] comes from former publications

such as [8]. This principle is used in the characterization of mechanical behavior

of materials at small scales. By this techniques a mechanical properties can be

determined directly from indentation load and displacement measurements without

the need to image the hardness impress. For this reason, the method has become

a primary technique for determining the nano-mechanical properties of thin

films and small structural features.

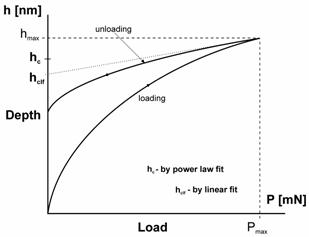

Fig. 2. One cycle of load-displacement data and contact

depth determination.

In principle the method was developed to

measure the hardness and elastic modulus of material from indentation

load-displacement data obtained during one cycle of loading and unloading

(Fig. 2). Parameter

P is the load and h the displacement relative to the

initial non-deformed surface. The

method is essentially an extension of the method proposed by Doerner and Nix [8]

(linear fitting – Fig. 2). Experiments have shown that unloading curves

are distinctly curved and P-h

raw data are usually well approximated by the power law

relation (1). Where a , hf and m are

constants.

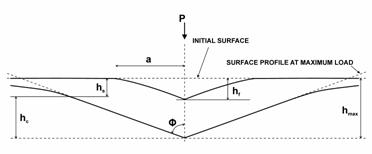

Fig. 3. Schematic illustration of the unloading

process [6, 7].

There are three

important quantities that must be measured from the curves. The maximum load Pmax, the maximum

displacement hmax and S the elastic unloading stiffness [7] (contact

stiffness [9]) defined (3) as the slope of the upper portion of the

unloading curve during the initial stages of unloading. Another important quantity

is the final depth hf the

permanent depth of penetration after the indenter is fully unloaded. The

accuracy of hardness and modulus measurement depends on how well these

parameters can be measured experimentally.

There are a

cross section of an indentation and the analysis parameters in Fig. 3. Total

displacement is written as (2). Distance hs

is the displacement of the surface at the contact perimeter.

The contact

depth hc (likewise called

plastic depth [8]) is the depth of indenter in contact with the

sample under maximal load (4). The geometric constant for the Berkovich

indenter e = 0,75. This value comes

from modelling [6] by a paraboloid geometry.

The area of

contact is determined by the geometry of the indenter and the depth of contact

by area function (5) which relates the cross-sectional area of the

indenter to the distance from its tip. This function must be established

experimentally prior to analysis. For a perfect Berkovich indenter the Ac = 24,5·hc2. A real

indenter is never perfect due to some tip rounding. The function may be determined

for an example as (6) type where L

and K are constants.

Measurements of

the initial unloading slope can be used to determine the reduced modulus Er. The reduced modulus is

related to the contact area and measured stiffness by (7).

The equation (8) takes

account effects of non-rigid indenters on the load-displacement behaviour. Ei and ni are

Young´s modulus and Poisson´s ratio for the indenter (diamond) which can be

taken as 1 141 GPa and 0,07 respectively [5], E and n are properties of the sample.

The data

obtained using the Oliver-Pharr method can be used to determine the indentation

hardness defined by equation (9).

4. Experiment

We measured

both carbon samples stuck on the one dural sample holder by quick drying cyanoacrylate

industrial superglue Permabond. The silicon films we affixed by a wax on another

dural holder. The melting temperature of the wax is approximately 60°C.

The experiment

we programmed in the control NanoTest software. The indents we arranged to a matrix

(Fig. 4). The matrix consisted from several single indents in one column

measured at one maximum load with the indentation offset 30 mm. The dimension of the matrix in horizontal

axis is given by number of experiments at one maximum load. There is possible

up to 100 indentation experiments each containing up to 100 indentations to be

scheduled in the NanoTest control software [5].

Fig. 4. The matrix of indents defined in the NanoTest

software.

The experiment was controlled by electronic control unit and the computer. Before the auto-run we left the instrument and prepared samples at the constant temperature 26°C during 6 hours.

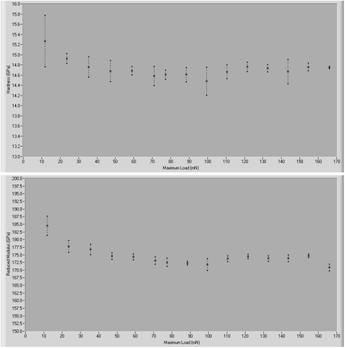

5. Results

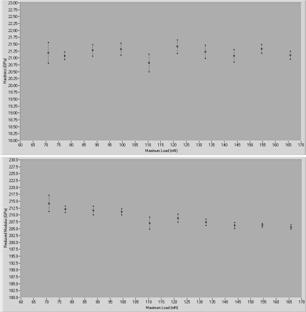

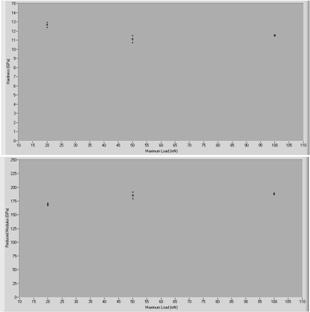

Determined dependencies

of hardness and reduced elastic modulus versus maximum load on measured carbon

films are in the following figures. Some measurement results on silicon film

are shown too.

Fig. 5. Hardness and reduced modulus vs. maximum load

on carbon film (sample no. 516).

Fig. 6. Hardness and reduced modulus vs. maximum load

on carbon film (sample no. 846-1).

Fig. 7. Hardness and reduced modulus vs. maximum load

on silicon film (sample no. 941).

Acknowledgements

This work was supported by Institutional Research Plan No. AV0Z10100522.

References

1. V. Kulikovsky, P. Bohac, F. Franc, A. Deineka,

V. Vorlicek, L. Jastrabik, Hardness, intrinsic stress, and structure of the a-C

and a-C:H films prepared by magnetron sputtering. Diamond and Related Materials, 10 (2001) 1076–1081.

2. G.M. Pharr, W.C. Oliver & D.R. Clarke,

Hysteresis and discontinuity in the indentation load-displacement behavior of

silicon. Scripta Metallurgica, 23 (1989)

1949–1952.

3. G.M. Pharr, W.C. Oliver & D.S. Harding, New

evidence for a pressure-induced phase transformation during the indentation of

silicon. Journal of Materials Research,

6 (1991) 1129–1130.

4. M.R. VanLandingham, Review of Instrumented

Indentation. Journal of Research of the

National Institute of Standards and Technology, 108 (2003) 249–265.

5. B. Beake, S. Goodes et al : Micro Materials

NanoTest User Manual Version 2.0. Wrexham 2003. Micro Materials Ltd.

6. W.C. Oliver, G.M. Pharr, An improved

technique for determining hardness and elastic modulus using load and

displacement sensing indentation experiments. Journal of Materials Research, 7 (1992) 1564–1583.

7. W.C. Oliver, G.M. Pharr, Measurement of

hardness and elastic modulus by instrumented indentation: Advances in

understanding and refinements to methodology. Journal of Materials Research, 19 (2004) 3–20.

8. M.F. Doerner, W.D. Nix, A method for

interpreting the data from depth-sensing indentation instruments. Journal of Materials Research, 1 (1986)

601–609.

9. J. Gong, H. Miao & H. Peng, Analysis of

the nanoindentation data measured with a Berkovich indenter for brittle

materials: effect of the residual contact stress. Acta Materialia, 52 (2004) 785–793.