CRYSTALLOGRAPHY

OF THE Sb-Te-Ni SYSTEM

F. Laufek1,3,

M. Drábek1, R. Skála2, I. Císařová3

1Czech

Geological Survey, Geologická 6, Praha 5, 152 00, Czech Republic

2 Institute of Geology, Academy of Sciences of the Czech Republic, Rozvojová 135, Praha 6, 165 02, Czech Republic

3 Faculty of Science, Charles University, Hlavova 8, , Praha 2, 128 43, Czech Republic

The new unnamed

nickel antimonide telluride Ni2SbTe2 was found as 6

μm grain by Vavřín and Frýda [1] at the Kunratice Cu-Ni deposit (North

Bohemia). This ternary phase is in a close association with melonite (NiTe2);

this assembly is included in pyrrhotite (Fe1-xS). In order to

determine the crystal structure of this phase (from the synthetic analogue) and

to further explore the Ni-Sb-Te phase diagram, the crystallography of this

ternary system was investigated. The phases were prepared using the silica

glass tube method. Our experiments were performed in the Experimental laboratory

of Czech Geological Survey. High-purity elements – tellurium (99.999 %),

antimony (99.99 %) and nickel (99.995 %) were used as starting materials.

Before being used for syntheses, nickel was heated for 1 hour in a stream of H2

at 800 ˚C. Carefully weighted samples were loaded into the high purity

silica tubes and tightly fitting silica rods were placed on the top of the

reagents in order to reduce the vapour volume during heating. The silica tubes

with the charge were sealed under vacuum and then heated in the horizontal

furnaces in which the temperature was controlled electronically. The maximum

temperature variation did not exceed 4 ˚C. The samples were heated at

400˚C or at 800˚C for three weeks. The experiments were terminated

either by quenching in a cold bath or by slow controlled cooling to room

temperature.

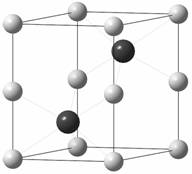

The crystal

structure of the new phase Ni2SbTe2 prepared at

800˚C (experiment terminated by quenching), determined from X-ray single

diffraction data, is hexagonal, NiAs type, with lattice parameters: a = 3.9108(2), c = 5.2489(3) Å, space group P63/mmc (no.

194). The antimony and tellurium occupy the crystallographic position 2c; the position 2a is occupied by nickel atoms (Fig. 1)

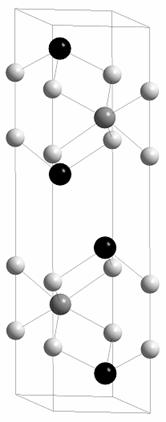

The crystal

structure of Ni2SbTe2 prepared at 400 ˚C (experiment

terminated by slow controlled cooling to room temperature within interval 22

hours), originally described by [2], refined from single X-ray diffraction

data, is hexagonal with lattice parameters

a = 3.9110(2), c = 15.696(1) Å, space group P63/mmc (no. 194). The antimony and tellurium atoms occupy different

crystallographic positions, antimony 2c

and tellurium 4f. (Fig. 2). The

crystal structure can be described as “hybrid” of NiSb and NiTe2

with an elongated c-axis. In NiSb structure, the close packed anion layers are

all Sb with ABAB stacking and all octahedral holes are filled with Ni. If every

third plane of Ni atoms is removed from NiSb and Sb replaced with Te in two out

of three layers, we can obtain the Ni2SbTe2 structure

(low temperature modification). The atom stacking sequence is CABCAC (A – Ni, B

– Sb, C – Te). The interlayer Te – Te distance is 3.543 Å. It is also to

be noted that this interatomic distance is larger than Te2

pair-cointaining phases (2.763 Å in HfTe2 and 2.793 Å in

ZrTe2 ) or in elementary Te (2.84 Å) [3], but shorter than the van der Waals distance

4.12 Å

(default van der Waals radius for Te is taken

from [4]). The weak

interlayer Te bonding results in a layered structure which corresponds to

plate-like morphology of crystals.

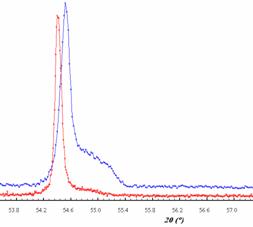

The situation

in the case of crystal structure of Ni2SbTe2 prepared at

400˚C (experiment terminated by quenching) is more complicated.The X-ray

powder diffraction pattern corresponds to the high temperature phase,

nevertheless diffraction profiles of 201

and 110 lines are asymetrical. This

assymetry disappears in the powder pattern of Ni2SbTe2

prepared at 800 ˚C (experiment terminated by quenching, Fig. 3). On the

Selected Area Electron Diffraction (SAED) pattern of reciprocal planes h0l it is possible to observe weak

reflections near 1/3 and 2/3 of the distance between the sharp strong

diffractions. These weak reflections are systematically shifted from 1/3 to the

left and from 2/3 to the right, i.e. closer to the sharp strong diffraction.

In fact, there

is a large number of compounds that exhibit Sb – Te bonding in which Sb is

formally cationic. Examples of such compounds include K3SbTe3,

TlSbTe2, SnSb2Te4, BaSbTe3 and NaSbTe2 [2]. In many compounds the Sb and Te atoms are

mixed on the same crystallographic site and thus are not new structure types.

These include e.g. Ni2SbTe, Mn2SbTe, Co2SbTe,

FeSbTe, Pd2SbTe and Cr2SbTe [5]. Virtually, there are

very few compounds which have Sb and Te atoms on distinct crystallographic

positions. Examples of such compounds are Ni7-δSbTe2,

Cu9.1Sb3Te and the new compound Ni2SbTe2.

Our research showed that the crystal structure of this phase depends on the

temperature during the formation.

The phase Ni2SbTe2 forms a solid solution with end members having a composition of 42,1 % Ni, 13,0 % Sb, 44,9 % Te and 43,0 % Ni, 28,4 % Sb, 28,6 % Te (at.%) at 400ºC. The most characteristic feature is a small change of the nickel content as well as significant differences of the antimony and tellurium content

This work was supported by

a Grant Agency of Charles University (project number 43-203391).

This work was supported by

a Grant Agency of Charles University (project number 43-203391).

![]()

Fig. 1. Crystal structure of Ni2SbTe2 prepared at 800˚C (experiment

terminated by quenching)

![]()

Fig. 2. Crystal structure of Ni2SbTe2 prepared at 400˚C (experiment terminated by slowly cooling to room temperature)

Fig. 3. Diffraction profile of 110 line of Ni2SbTe2 prepared at 400˚C (above) and at 800˚C, CoKα1

1. Vavřín, I. & Frýda, J. Věštník ČGÚ, 73 (1998) 177-180.

2. Reynolds T.K., Kelley R.F. & DiSalvo F.J. J. Alloy Comp., 366 (2004) 136 -144.

3. Bensch, W., Heid. W., Muhler, M., Jobic, S., Brec, R. & Rouxel, J. J. Solid State Chem. 121 (1996) 87 - 94.

4. Bondi, A. J.Phys.Chem. 68 (1964) 441-451.

5. Inorganic Crystal Structure Database (ICSD), 2003