Y-hexaferrite thin films deposited by chemical solution deposition on different substrates studied by XRD

Radomír Kužel1, Milan Dopita1, Lukáš Horák1, Josef Buršík2

1Charles University,

Faculty of Mathematics and Physics, Ke Karlovu 5, Praha 2 121 16, Czech

Republic,

2Institute of Inorganic Chemistry of the Czech Academy of Sciences,

v.v.i., Husinec-Řež 1001, 250 68, Czech Republic

radomir.kuzel@matfyz.cuni.cz

Thin films of several phases of hexagonal ferrites with a potential of magnetoelectric effect (ME) were prepared by a chemical solution deposition method, and the number of processing parameters was tested and optimized with the of minimizing the amount of impurities that could spoil the magnetic properties of the final material. With the aim of preparation of highly oriented ferrite films, several substrates were used, and different substrate/seeding layer/ferrite layer architectures were proposed. [1-5].

The mechanism of ME in Y-type hexaferrite films appears to be significantly influenced by lattice parameters. New Y-ferrite phases were prepared with the composition BaxSr2-xCo2Fe11.1Al0.9O22, and it was found that the magnetic structure is non-colinear ferrimagnetic type. These films could be prepared with good out-of-plane and in-plane orientation directly on STO - SrTiO (111) substrate, but the M-phase seeding layer usually leads to better results. The ME effect was identified to be maximum for equal content of barium and strontium but the dependence on x is now studied in more detail. In the project, we investigate the influence of the degree and type of preferred orientation of the films as well as their real structure on the ME effect. By using different substrates, different preferred orientations and strains can be obtained.

Symmetrical q-q scans often indicated a strong preferred orientation (000l) on STO (111). This is the so-called out-of-plane orientation. In case of fiber texture, its degree can be well characterized by the w scans (rocking curves). For the estimation of the alignment of planes perpendicular to the substrate, measurement of additional asymmetric Bragg reflections is necessary, simply by the φ scans (rotation on the axis perpendicular to the film plane). The lattice parameters of the films were obtained by evaluating the maxima positions of about 30 diffraction profiles measured at different sample inclinations and φ angles corresponding to the maxima, i.e., by creating a powder-like pattern [6].

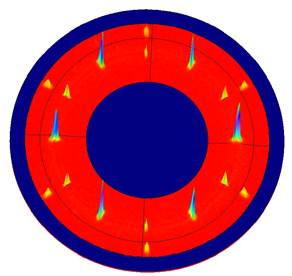

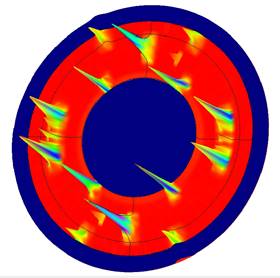

Several sets of Y-films were investigated. Films with different thicknesses were deposited on the STO substrate with orientations (111), (110), (100), and ceramics. In all cases, (00l) textures of Y-phases of different degrees were observed but only for (111) also a strong (111) texture was detected, as it can be expected. Then other substrates were used - MgO (111), LaAlO3 (111) - LAO, stabilized cubic zirconia (ZrO2) and MgAl2O4 (111). In this case, significant out-of-plane and in-plane orientations of Y-films were observed for LAO substrates with FWHMs of both w and φ scans of approximately 0.4°. For MgO substrates both orientations were also indicated with a slightly wider FWHMs (over 1°). On zirconia, the preferred orientations are relatively poor with clear domains in in-plane orientations. Another set of substrates used were differently oriented sapphire substrates (rhombohedral Al2O3) – c-cut (000l), a-cut (11-20), m-cut(10-10), r-cut (1-120). It seems that different pronounced textures of Y-hexaferrites can grow there including the (h00) orientation on a-cut of substrate, or (hh0) on m-cut of substrate. Some illustrations of preferred orientation with a few domains are shown in Fig. 1.

|

|

|

|

Figure 1. Illustrations of preferred orientation of Y-films. Partial pole figures (119) for the film grown on MgAl2O4 substrate (left), and (024) for the film grown on Al2O3 a-cut. |

|

1. Shin, KW; Soroka, M.; Shahee, A; Kim, KH;

Buršík, J.; Kužel, R; Vronka, M; Aguirre, MH: Advanced Electronic Materials.

v. 8 (2022).

2101294.

2. J. Buršík, R. Uhrecký, D. Kaščáková, M. Slušná, M. Dopita, R. Kužel, Journal of the European Ceramic Society 36 (2016) 3173–3183.

3. R. Uhrecký, J. Buršík, M. Soroka, R. Kužel, J. Prokleška , Thin Solid Films. 622 (2017) 104–110.

4. M. Soroka, J. Buršík, R. Kužel, J. Prokleška, M.H. Aquirre, Thin Solid Films, 726 (2021) 138670.

5. M. Soroka, J. Buršík, R. Kužel, L. Horák, J. Prokleška, M. Vronka & V. Laguta. Journal of European Ceramic Society. 43, (2023) 6916-6924.

6. R. Kužel, J. Buršík, M. Dopita, L. Horák, M. Soroka, Materials Structure 30 (2024) 328-331.

The authors appreciate the support by the grant of the Czech Grant Agency, no. 24-12710S.