Crystallization with an automated apparatus for temperature-controlled flow-cell dialysis with real-time visualization

N. Junius3,1,2, E. Oksanen1,2,3, M. Terrien2,1,3, C. Berzin3,1,2, J-L. Ferrer3,1,2, M. Budayova-Spano1,2,3*

1Univ. Grenoble Alpes, IBS, F-38044 Grenoble, France, 2CNRS, IBS, F-38044 Grenoble, France, 3CEA, IBS, F-38044 Grenoble, France

*monika.spano@ibs.fr

Much instrumentation developments in crystallization have concentrated on massive parallelization assays and reduction of sample volume per experiment to find initial crystallization conditions. Yet improving the size and diffraction quality of the crystals for diffraction studies often requires decoupling crystal nucleation and growth. This in turn requires controlling variables such as precipitant and protein concentration, equilibration rate, temperature, that are all difficult parameters to control in the existing setups.

We have developed a temperature controlled dialysis button for our previous device [1] and also constructed a prototype of an automated integrated apparatus for the rational optimization of crystal growth by mapping and manipulating temperature-precipitant concentration phase diagrams [2]. Moreover as the crystallization process is based on dialysis, it allows to explore crystallization conditions without consuming the protein sample, so the conditions can be changed in a reversible fashion.

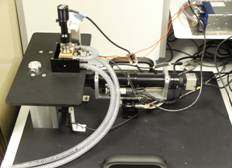

This new crystallization bench (Figure 1) comprises a flow-cell dialysis set-up in thermal contact with Peltier modules. A microscope-mounted video camera allows for real-time observation in the dialysis chamber. There is also a dry air system preventing condensation. Each parameter is controlled using the user-friendly supervision software, resulting in reducing any handling on the bench during the experiment. The control software of the apparatus, written under LabVIEW (Figure 2), enables real-time visualization of the dialysis chamber, direct measurements of crystal size, temperature control thanks to a PID electronic temperature controller in the range of 233-353±0.1K and control of the chemical composition thanks to a pressure-driven flow controller.

This instrument, makes possible the rational optimization of large crystal growth based on knowledge of a multidimensional phase diagram.

|

|

|

Figure 1. Photograph of the new apparatus for the temperature-controlled flowing reservoir dialysis. |

Figure 2. Graphical user interface for system setup, viewing, monitoring, treating images, recording sequences, temperature control, pumping solutions, measuring crystal. |

1. Budayova-Spano, M., Dauvergne, F., Audifren, M., Bactivelane, T., Cusack, S. (2007). Acta Cryst. D63, 339-347.

2. Budayova-Spano, M. (2010). Patent FR10/57354, UJF, (extension: EP117730945, US13821053, JP2013528746).