First test measurements at the new structure powder diffractometer (SPODI) at the FRM-II

R. Gilles1,

M. Schlapp1,2, M. Hoelzel1,2, B. Krimmer1, H.

Boysen3, H. Fuess2

1 Technische Universität München, ZWE FRM-II, Lichtenbergstr. 1, 85747

Garching, Germany.

2 Technische Universität Darmstadt, FB Material- und Geowissenschaften,

Petersenstr. 23, 64287 Darmstadt, Germany.

3 Ludwig-Maximilians-Universität, Depart. für Geo- und Umweltwissenschaften,

München, Theresienstr. 41, 80333

München, Germany.

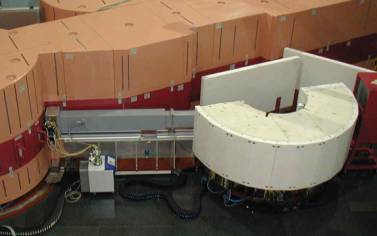

In a collaboration of the Technische Universität Darmstadt and the Ludwig-Maximilians-Universität München, funded by german government (BMBF), we build up the new Structure Powder Diffractometer (SPODI) at the neutron source FRM-II in Garching near München (see Fig. 1). The instrument operates in the angle-dispersive mode with a previously selected wavelength. This contribution will give an overview of the status and the innovations of new components included in the concept [1, 2, 3]. Particular highlights of the set-up are for example the sophisticated supermirror neutron guides (trumpet shape) for thermal neutrons, the high take-off angle 155° realized with 17 slabs of an unconventional orientation (551) of the germanium monochromator (each slab consists of 37 wafers !), the 300 mm high collimators with tapered sidewalls to enlarge the effective detection area, the position sensitive detector providing 2D array detection with multifarious evaluation procedures, the space optimized shielding with different special materials (to improve the signal to background ratio) etc. The realisation of this layout aims at higher intensity, improved resolution and better profile shape. Monte Carlo simulations of the complete instrument including the sample for testing were carried out to match the components. First test measurements of single components at other neutron facilities promise many applications of SPODI.

Fig. 1: Set-up of the Structure Powder DIffractometer SPODI at the FRM-II.

The design and status of the new Structure POwder DIffractometer (SPODI) is reviewed. To solve complicated structures reliably by powder diffraction not only high resolution and intensity are essential, but, in particular, also ²good² peak profiles that can be described as perfect as possible. For strongly overlapping reflections, uncertainties in the exact shape can lead to a wrong distribution of the intensities. Moreover, such knowledge virtually increases the resolution of the instrument far beyond that given by the widths of the peaks. Similar arguments hold for a good peak to background ratio which can be achieved not only by a low background, but also by narrow tails of the peaks. Finally, such ²good² peak shapes should be maintained up to large scattering angles 2q. Based on these considerations computer simulations have been used to optimise both each single component and their interaction along the instrument. The resulting concept together with test measurements of single components at neutron sources have been described in reference [1, 2, 3, 4, 5]. The high flux at the sample position with neutrons of very low vertical divergence because of the 5m distance to the monochromator allows the unique possibility to integrate a small-angle apparatus in the whole system [6].

Currently

the alignment of the single monochromator slabs is done to optimize the

focusing of the beam at the sample position

(Fig.

2).

Fig. 2: Photograph of the germanium monochromator (551) installed in the monochromator drum. The inset displays rocking curves of a single monochromator slab.

[1] Gilles R., Artus G., Saroun J., Boysen H., Fuess H., Physica B, 276 – 278, (2000), 87.

[2] Gilles R., Saroun J., Boysen H., Fuess H., Proceedings of the HERCULES X EuroConference (2000), Grenoble.

[3] Gilles R., Krimmer B., Saroun, Boysen H., Fuess H., Materials Science Forum, 378-381 (2001), 282.

[4] Gilles R., Krimmer B., Boysen H., H. Fuess, Applied Physics A 74 [Suppl.] (2002), 148.

[5] M. Hoelzel, R. Gilles, M. Schlapp, H. Boysen, H.

Fuess, to be published in Physica B.

[6] M. Schlapp, M. Hoelzel, R. Gilles, A. Ioffe, T.

Brueckel, H. Fuess, H. von Seggern, to be published in Physica B.

Acknowledgement

The

support of this study by the German BMBF under grant FKZ03-FU5FRM is gratefully

acknowledged.